TIME AND COST EFFICIENCY ANALYSIS OF ACEH TENGAH REGENCY POM WORKSHOP PROJECT: A CRITICAL PATH METHOD APPROACH

Hafnidar A. Rani 1![]()

![]() ,

Fida Filaya Maina 1

,

Fida Filaya Maina 1![]() , Muhammad Shafly Aqsha 2

, Muhammad Shafly Aqsha 2![]() , Muhammad Hafidz Mubarak 3

, Muhammad Hafidz Mubarak 3![]()

1 Department

of Civil Engineering, Universitas Muhammadiyah Aceh, Banda Aceh, Aceh,

Indonesia

2 Faculty

of Computer Science, Universiti Tun Hussein Onn Malaysia, Johor, Malaysia

3 Department of Information Technology, Universitas Ubudiyah Indonesia,

Banda Aceh, Indonesia

|

|

ABSTRACT |

||

|

The study

addresses construction delays in the Aceh Tengah Regency POM Workshop

project, valued at IDR 6,414,000,000 and spanning approximately 1,507 m2

across two floors. Motivated by the need for a comprehensive understanding of

activity relationships and critical paths, the research aims to assess

project duration, costs, and efficiency. Employing the Critical Path Method

(CPM) due to data constraints, the study elucidates activity dependencies,

network planning, and critical paths. Data collected from relevant

stakeholders include schedule and cost budget plans. The analysis reveals a

potential acceleration of 21 days, reducing the project duration from 126 to

105 days with a 99.74% probability. Cost control indicates an escalation to

IDR 6,949,573,170.20 after calculating direct costs, with a daily increase of

0.92%. The findings underscore the significance of CPM in project management,

offering insights into optimizing timelines and costs. The study highlights

the importance of efficient project management methodologies in addressing

construction delays and managing project budgets effectively. |

|||

|

Received 05 April 2024 Accepted 06 May 2024 Published 21 May 2024 Corresponding Author Hafnidar

A. Rani, hafnidar.ar@unmuha.ac.id DOI 10.29121/IJOEST.v8.i3.2024.604 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Critical Path

Method, Time and Cost, Construction Project |

|||

1. INTRODUCTION

The construction industry plays a vital role in societal development, enriching communities through infrastructure projects aimed at improving quality of life. However, effective project management within this sector is essential for the timely and cost-efficient delivery of these initiatives Rani (2021). Traditional scheduling methods, such as the Gantt chart and S-curve, have limitations in presenting comprehensive project information, activity interdependencies, and critical path identification, hindering efficient project execution Syammaun et al. (2019). To address these shortcomings, this study adopts the Critical Path Method (CPM) to enhance time and cost control in construction projects Rahma & Kamandang (2023).

Building upon prior research Wicaksono & Setiawan (2023) that has highlighted the impact of project scheduling methods on cost outcomes, this study seeks to contribute to the optimization of construction project management practices. By employing CPM, the research aims to uncover insights into the interrelationships among project activities and critical paths, enabling better prioritization and resource allocation Yang & Kao (2012). Through a contextualized narrative, the study immerses the reader in the challenges and complexities of construction project management, illustrating the need for innovative approaches to address scheduling and cost control issues.

The study's critical question emerges from firsthand experiences and observations within the construction industry, highlighting the necessity for improved project management techniques. The goal is to investigate how CPM can offer more comprehensive insights into project scheduling and cost implications, ultimately informing strategies for efficient project delivery. By weaving together personal insights, industry context, and methodological rationale, the introduction sets the stage for the study's objectives, emphasizing the importance of addressing time and cost management challenges in construction projects.

In summary, this study builds upon existing literature by

adopting CPM as a theoretical and operational framework to address time and

cost management challenges in construction projects. Through a thorough

exploration of project scheduling methods and their implications, the research

aims to contribute to the advancement of construction project management

practices and fill existing research gaps in the field.

2. MATERIALS AND METHODS

According to Rani (2021), project management

involves the processes of planning, organizing, leading, and controlling the

activities of members and resources to achieve the goals set by an organization

or company. To achieve these goals, management encompasses several functions,

including the following:

1) Planning

involves setting organizational goals and determining the strategies needed to

achieve them. Planning is future-oriented due to the uncertainty associated

with the future. It entails establishing initial steps to enable an

organization to achieve its objectives and involves efforts to anticipate

future trends and determine appropriate strategies and tactics to realize

organizational goals.

2) Organizing

involves assigning tasks and developing organizational structures that align

with the company's objectives. Organizing aims to coordinate various resources,

including human resources, to function optimally and fulfill their respective

roles and functions effectively.

3) Directing:

It entails actions aimed at ensuring that all group members strive to achieve

goals in line with the plan. The directing process aims to guide or control so

that work is carried out effectively and efficiently.

4) Controlling

involves assessing the activities that have been carried out. The controlling

function determines the quality of services or products produced.

According to Ammar et al. (2023), the breakdown of project

costs is the calculation of the total cost required for materials, labor, and

other expenses related to the construction or implementation of the building or

project. The cost budget plan (RAB) is an estimate of the costs required for

each task in a construction project, resulting in the total cost needed to

complete the project Al-Enezi & Al-Sabah (2023).

Optimization analysis can be defined as a process of decomposing project

duration to achieve the best acceleration duration using various alternatives

considered from a cost perspective Saleh et al. (2023). The process of shortening

activity time in a network to reduce time on critical paths, thus reducing the

total completion time, is referred to as project crashing. Time and cost have a

significant impact on the success or failure of a project Daoud et al. (2023).

To develop the time and cost planning for project implementation, it is

necessary to study job specifications, break down tasks, examine the relationships

between activities, create a network plan, conduct time and cost analyses for

each activity, create tables for time and cost implementation, optimize time

and cost processes, and ultimately achieve optimal time and cost Beste & Klakegg (2022).

Network planning (NWP) is a graphical representation of the activities

required to achieve a final goal Rani (2016). To achieve this goal,

symbols are required, consisting of:

1) Arrows

represent activities. Activities are defined as tasks that require a specific

duration or time frame for the use of resources. The arrowhead indicates the

direction of each activity, showing that an activity starts from the beginning

and progresses forward to the end, with the direction from left to right.

2) Small

circles represent nodes, indicating events. Events are defined as the start or

end of an activity or task.

3) Dummy (dashed

arrows) represents all activities, meaning activities that do not require

duration or resources.

With the Critical Path Method (CPM), the total time required to complete

various stages of a project is considered known, as is the relationship between

the resources used and the time required to complete the project Pramesti & Listyawan (2023). The network planning

technique used in the Critical Path Method (CPM) employs Activity on Arrow

(AOA), where arrows represent activities or tasks with various activity

notations Permatasari et al. (2023). The Critical Path Method

(CPM) is a significant planning technique as it can provide answers to

project-related questions, including:

1) Estimation

of the project completion time.

2) Determination

of the most economical project schedule.

3) Identification

of the sequence of project activities with numerous components and complex

dependency relationships.

4) Identification

of critical activities crucial for overall project completion, which may cause

project delays,

5) Assessment

of the impact of delays in specific activities on the project's schedule

target.

6) Evaluation

of whether the project is on schedule, behind schedule, or ahead of the

predetermined schedule at a specific date.

7) Assessment

of whether the expenditures at a specific date are equal to, less than, or

greater than the budgeted amount.

8) Evaluation

of the availability of sufficient resources to complete the project on time.

9) Minimization

of resource utilization fluctuations.

Determination of the best approach to expedite project completion within

minimal costs if a shorter duration is desired for the project.

PERT can be considered a development technique of CPM Astari et al. (2021), Aziz (2014). In PERT, three-time

estimates are used for each activity because the completion time of activities

cannot be determined with certainty, unlike in CPM, where a fixed time is used Aziz (2014), Trietsch & Baker (2012). PERT utilizes three

estimation figures representing optimistic time (o), most likely time (m), and

pessimistic time (p) Ketut (2015).

1) Optimistic

Time (O) is the minimum time, assuming an activity is completed under ideal

conditions where everything progresses smoothly without any issues. The

optimistic time estimate has a very low likelihood of being achieved. Formula:

To = Tm - 5%

2) Most

Likely Time (M) is the time, based on the estimator's judgment, representing

the most frequent duration for completing an activity if the work is repeated

under similar conditions.

3) Pessimistic

Time (P) is the maximum time assuming an activity is completed under adverse

conditions where execution is disrupted by various issues such as bad weather,

damages, personnel problems, material supply issues, and so on. The pessimistic

time estimate has a very low likelihood of being achieved. Formula: Tp = Tm +

10%.

A project represents the relationship between time and cost, where the

cost refers to direct costs such as labor costs, excluding indirect costs such

as administrative expenses, among others.

2.1. Research Stages

1) Problem

identification involves the expression of ideas or concepts through a

literature review, problem formulation, determination of research objectives,

methods used, problem formulation, and problem limitations.

2) Literature

Review: In this research, references are collected by reviewing literature

books, journals, the internet, and previous studies related to the ongoing

research.

3) Data

Collection: All necessary data for the research is collected through field studies

to obtain primary data. Primary data is obtained through direct communication

with relevant parties and obtaining permission to acquire data to support the

discussion of this research, as well as literature studies to obtain secondary

data for this research.

4) Data

Processing: After completing the data collection, data processing is carried out

using the CPM manually for time control and cost calculation. Additionally,

PERT is used only to assist in time control in calculating accelerated time

probabilities.

5) Critical

Path Method (CPM): This research will discuss the time and cost

obtained after implementing time and cost control using the CPM manually with

the planned stages in this research. The steps to be taken are as follows:

·

Develop a Work Breakdown Structure (WBS) for

each planned project activity.

·

Calculate the duration and cost of work based

on the planned schedule of the project.

·

Establish the dependencies of work items

based on the planned time to create logical dependencies related to project

activities.

·

Create network planning using the Critical

Path Method (CPM) manually. Each arrow will represent an activity.

·

Determine float time to identify delayed

activities. This includes calculating total float, free float, and independent

float.

·

Determine the critical path, which is chosen

because it has the longest duration and any delays will affect other

activities. The critical path will be highlighted in red in the network

planning for easy identification.

·

Calculate probabilities using PERT on the

accelerated network planning with target duration. This involves calculating

three times, then the standard deviation and variance, to obtain the z-value

for the probability percentage.

·

Calculate project costs using the equations

presented in the literature review and CPM manually. Cost calculation using the

CPM method involves equations as presented in the literature review.

3. RESULTS AND DISCUSSIONS

In creating this work breakdown, it is essential first to determine the

types of tasks to be performed, then arrange them according to the list of

tasks that need to be done first. After decomposing the work, normal work

duration calculations are performed.

1)

Compiling

Normal Work Duration and Costs

Based on the project's planned schedule data, the normal work duration

is 126 days, and the total normal direct cost is IDR 6,414,000,000.00 (six

billion four hundred and fourteen million Indonesian Rupiah). The work duration

is adjusted based on the number of work items.

2)

Compiling

Network Planning with CPM

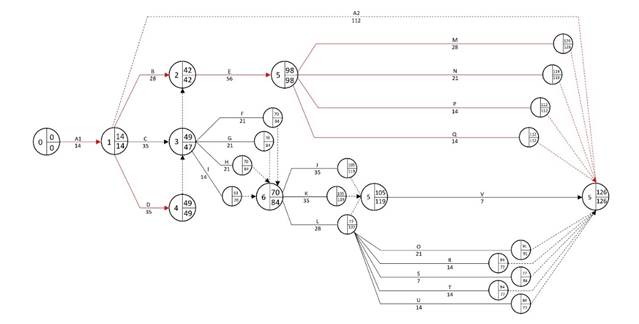

After establishing the dependencies between work items in the Aceh Tengah Regency POM Workshop project, a network plan using the Critical Path Method (CPM) can be created. The critical path, which has the longest duration, is identified, ensuring no delays occur on this path, as shown in Figure 1.

Figure 1

|

Figure 1 Critical Path Method with a Duration of 126 Days |

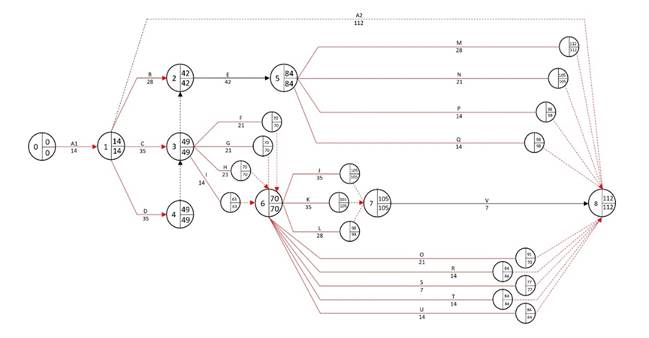

Furthermore, an alternative was made to accelerate the

project duration by 14 days during the wall construction marked with the symbol

E. Based on the acceleration diagram, it was found that all paths became

critical, with the project duration becoming 112 days, as presented in Figure 2.

Figure 2

|

Figure 2 Critical Path Method with a Duration of 112 Days |

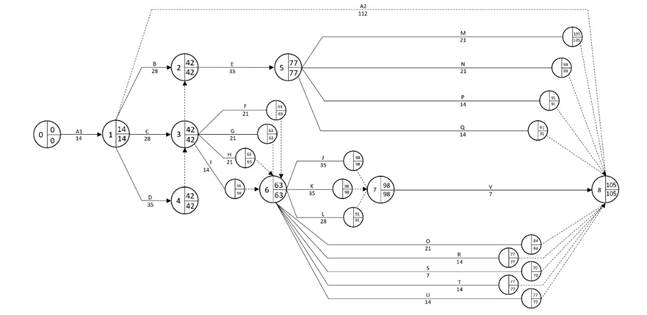

Therefore, an additional acceleration of 7 days was

implemented, resulting in all paths becoming critical again with a project

duration of 105 days, as shown in Figure 3.

Figure 3

|

Figure 3 Critical Path Method with a Duration of 105 Days |

3) Determining

the Critical Path

After creating a project scheduling diagram using the Critical Path

Method (CPM), it is found that there are 4 critical paths in the network

planning marked by symbols (A-B-E-M), (A-B-E-N), (A-B-E-P), and (A-B-E-Q) with

a work duration of 126 days. These paths are chosen because they have the

longest duration and have been calculated for Total Float, Free Float, and

Independent Float.

Table 1

|

Table 1 Calculation of Float Values After Acceleration by 7 Days |

|||||||||

|

No |

Activity Description |

Event |

SPA |

L |

SPL |

TF |

FF |

IF |

|

|

1 |

A |

Standard preparation work

and RK3K construction work |

0-1 |

14 |

14 |

0 |

0 |

0 |

0 |

|

2 |

B |

Concrete pavement work |

1-2 |

42 |

28 |

14 |

0 |

0 |

0 |

|

3 |

C |

Fence work |

1-3 |

42 |

28 |

14 |

0 |

0 |

0 |

|

4 |

D |

Block paving work |

1-4 |

42 |

28 |

14 |

0 |

0 |

0 |

|

5 |

E |

Curbing work |

2-5 |

77 |

35 |

42 |

0 |

0 |

0 |

|

6 |

F |

Earthwork and foundation

work |

3-6 |

63 |

21 |

42 |

0 |

0 |

0 |

|

7 |

G |

STR 0.00 work |

3-6 |

63 |

21 |

42 |

0 |

0 |

0 |

|

8 |

H |

STR 4.20 work |

3-6 |

63 |

21 |

42 |

0 |

0 |

0 |

|

9 |

I |

Floor 3 STR work |

3-6 |

63 |

14 |

42 |

7 |

7 |

7 |

|

10 |

J |

Steel roof work |

6-7 |

98 |

35 |

63 |

0 |

0 |

0 |

|

11 |

K |

Wall work |

6-7 |

98 |

35 |

63 |

0 |

0 |

0 |

|

12 |

L |

Floor, wall, and ceiling

cover work |

6-7 |

98 |

28 |

63 |

7 |

7 |

7 |

|

13 |

M |

Painting and column

relief work |

5-8 |

105 |

28 |

77 |

0 |

0 |

0 |

|

14 |

N |

Frame, door, and window

work |

5-8 |

105 |

21 |

77 |

7 |

7 |

7 |

|

15 |

O |

Railing work |

6-8 |

105 |

21 |

63 |

21 |

21 |

21 |

|

16 |

P |

Roof covering work |

5-8 |

105 |

14 |

77 |

14 |

14 |

14 |

|

17 |

Q |

Sanitation work |

5-8 |

105 |

14 |

77 |

14 |

14 |

14 |

|

18 |

R |

Electrical work |

6-8 |

105 |

14 |

63 |

28 |

28 |

28 |

|

19 |

S |

Plumbing and fire

extinguisher work |

6-8 |

105 |

7 |

63 |

35 |

35 |

35 |

|

20 |

T |

Air conditioning work |

6-8 |

105 |

14 |

63 |

28 |

28 |

28 |

|

21 |

U |

Ground water tank

structure work |

6-8 |

105 |

14 |

63 |

28 |

28 |

28 |

|

22 |

V |

Ground water tank

architecture work |

7-8 |

112 |

7 |

105 |

0 |

0 |

0 |

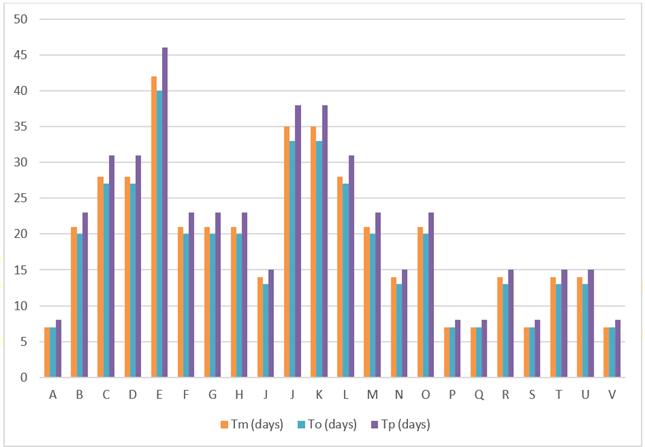

4) Calculation

of Triple Duration and Probability Using PERT

The use of this method aims to obtain probabilities, with the previous

accelerated time of 105 days in the network planning becoming the target

duration of 98 days. This method uses the calculation of three-time estimates:

optimistic time (To), standard time (Tm), and pessimistic time (Tp).

1) Calculation

of Triple Duration: This involves determining optimistic, most

likely, and pessimistic times. For example, for the standard preparation work:

2) Calculating

the Average Value (Te): Te is the average duration used for

constructing the PERT network.

3) Calculating

the Standard Deviation (Se): After obtaining the average value, the next

step is to calculate the standard deviation.

4) Calculating

the Variance (Ve): After calculating the standard deviation,

the variance is calculated.

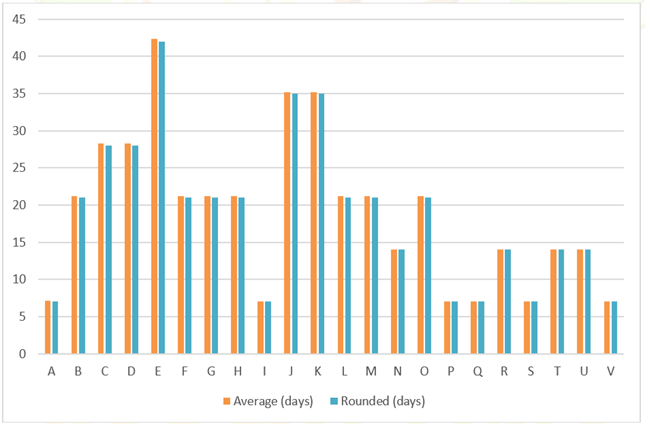

Figure 4

|

Figure 4 Calculation of Tm, To, Tp |

Figure 5

|

Figure 5 Calculation of Average Te |

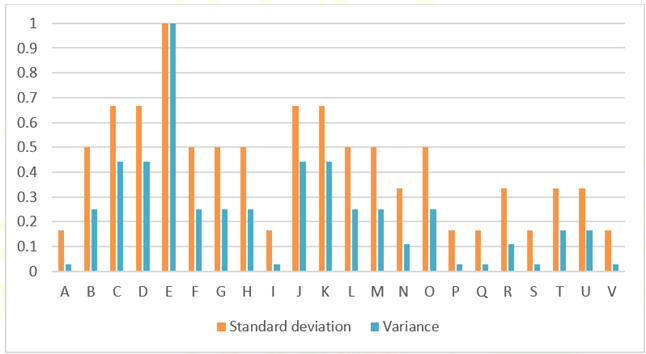

Using PERT analysis with Te and Ve values, the probability calculations

for critical path activities result.

Figure 6

|

Figure 6 Standard Deviation and Variance Calculation |

From the probability calculation results, it is determined that

completing the project within an accelerated duration of 98 days is not

feasible, reaching only 34.46%. Therefore, it is more efficient to use 105 days

as the probability reaches 99.74%.

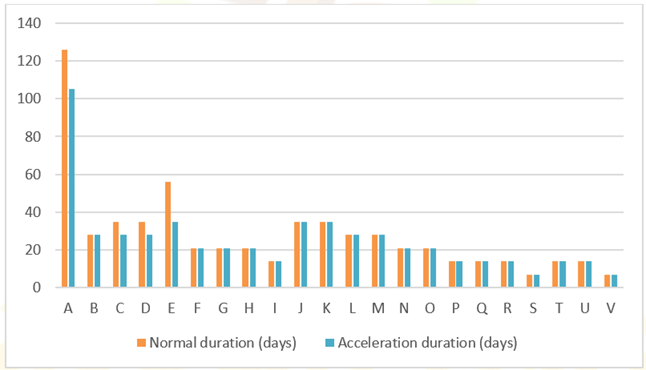

5) Time

Control

After implementing time control in the previous calculations, the next step is cost control based on the total cost of IDR 6,414,000,000.00 for both direct and indirect costs. However, in this cost control, only the normal direct costs amounting to IDR 5,778,378,378.38 are considered.

Figure 7

|

Figure 7 Time Control |

After calculating the daily costs with the normal duration in the table above, the next step is to calculate the costs after the duration is accelerated.

Table 2

|

Table 2 Cost Control |

|||||

|

No |

Activity |

Normal duration (days) |

Normal cost (IDR) |

Cost per day (IDR) |

Cost after acceleration

(IDR) |

|

1 |

A |

126 |

64,910,318.73 |

515,161.25 |

72,122,575 |

|

2 |

B |

28 |

763,494,628.39 |

27,267,665.29 |

763,494,628.12 |

|

3 |

C |

35 |

855,116,379.33 |

24,431,896.55 |

1,026,139,655.15 |

|

4 |

D |

35 |

903,506,599.34 |

25,814,474.26 |

1,084,207,919.12 |

|

5 |

E |

56 |

418,475,973.64 |

7,472,785.24 |

575,404,463.64 |

|

6 |

F |

21 |

73,353,273.99 |

2,619,759.75 |

73,353,273.99 |

|

7 |

G |

21 |

208,923,051.55 |

9,948,716.74 |

208,923,051.55 |

|

8 |

H |

21 |

191,325,984.81 |

9,110,761.18 |

191,325,984.81 |

|

9 |

I |

14 |

29,564,176.46 |

2,111,726.89 |

29,564,176.46 |

|

10 |

J |

35 |

417,469,486.63 |

11,927,699.81 |

417,469,486.63 |

|

11 |

K |

35 |

392,712,472.00 |

11,220,356.34 |

392,712,472.00 |

|

12 |

L |

28 |

418,986,902.07 |

14,963,817.93 |

418,986,902.07 |

|

13 |

M |

28 |

73,353,273.99 |

2,619,759.75 |

73,353,273.99 |

|

14 |

N |

21 |

152,409,097.68 |

7,257,576.08 |

152,409,097.68 |

|

15 |

O |

21 |

269,230,216.78 |

12,820,480.51 |

269,230,216.78 |

|

16 |

P |

14 |

57,750,000.00 |

4,125,000.00 |

57,750,000.00 |

|

17 |

Q |

14 |

3,024,500.00 |

216,035.71 |

3,024,500.00 |

|

18 |

R |

14 |

152,918,785.89 |

10,194,585.72 |

152,918,785.89 |

|

19 |

S |

7 |

15,588,000.00 |

2,226,857.14 |

15,588,000.00 |

|

20 |

T |

14 |

124,603,166.31 |

8,900,226.16 |

124,603,166.31 |

|

21 |

U |

14 |

37,477,919.77 |

2,676,994.26 |

37,477,919.77 |

|

22 |

V |

7 |

33,600,000.00 |

4,800,000.00 |

33,600,000.00 |

After performing the calculations above, the normal direct costs, which were previously IDR 5,778,378,378.38, increased to IDR 6,313,951,548.58. Hence, the cost control becomes greater than before, with an increase of IDR 535,573,170.2. The total cost after acceleration amounts to IDR 6,949,573,170.2.

Table 3

|

Table 3 Time and Cost Control |

|||||

|

No |

Activity |

Normal duration (days) |

Acceleration duration

(days) |

Normal Cost (IDR) |

Cost after acceleration

(IDR) |

|

1 |

A |

126 |

105 |

64,910,318.73 |

72,122,575 |

|

2 |

B |

28 |

28 |

763,494,628.39 |

763,494,628.12 |

|

3 |

C |

35 |

28 |

855,116,379.33 |

1,026,139,655.15 |

|

4 |

D |

35 |

28 |

903,506,599.34 |

1,084,207,919.12 |

|

5 |

E |

56 |

35 |

418,475,973.64 |

575,404,463.64 |

|

6 |

F |

21 |

21 |

73,353,273.99 |

73,353,273.99 |

|

7 |

G |

21 |

21 |

208,923,051.55 |

208,923,051.55 |

|

8 |

H |

21 |

21 |

191,325,984.81 |

191,325,984.81 |

|

9 |

I |

14 |

14 |

29,564,176.46 |

29,564,176.46 |

|

10 |

J |

35 |

35 |

417,469,486.63 |

417,469,486.63 |

|

11 |

K |

35 |

35 |

392,712,472.00 |

392,712,472.00 |

|

12 |

L |

28 |

28 |

418,986,902.07 |

418,986,902.07 |

|

13 |

M |

28 |

28 |

73,353,273.99 |

73,353,273.99 |

|

14 |

N |

21 |

21 |

152,409,097.68 |

152,409,097.68 |

|

15 |

O |

21 |

21 |

269,230,216.78 |

269,230,216.78 |

|

16 |

P |

14 |

14 |

57,750,000.00 |

57,750,000.00 |

|

17 |

Q |

14 |

14 |

3,024,500.00 |

3,024,500.00 |

|

18 |

R |

14 |

14 |

152,918,785.89 |

152,918,785.89 |

|

19 |

S |

7 |

7 |

15,588,000.00 |

15,588,000.00 |

|

20 |

T |

14 |

14 |

124,603,166.31 |

124,603,166.31 |

|

21 |

U |

14 |

14 |

37,477,919.77 |

37,477,919.77 |

|

22 |

V |

7 |

7 |

33,600,000.00 |

33,600,000.00 |

Based on the calculations above, it can be observed that

time and cost control change, resulting in more efficient time and cost

management. The calculation indicates a time acceleration of 105 days, compared

to the previous normal duration of 126 days, with a probability percentage of

99.74%. This means the project can be completed faster than 126 days.

Consequently, the project duration accelerates by 21 days and 0.83% per day.

Regarding cost control, the initial cost of IDR 6,414,000,000.00 increases to

IDR 6,313,951,548.58 when considering only the direct costs, showing an

increase of 0.92% per day. This amounts to a total of IDR 6,949,573,170.2.

Thus, the outcome of time and cost control demonstrates their interdependence;

if the project duration is accelerated, the cost will also increase

accordingly.

4. CONCLUSIONS and RECOMMENDATIONS

The implementation of time and cost control measures in the construction project of Loka POM in Aceh Tengah Regency has proven to be highly effective in optimizing project management, demonstrating the practical implications of employing such measures in construction projects. Through Critical Path Method analysis. This acceleration was further supported by probability calculations using the Program Evaluation and Review Technique, indicating completing the project within the shortened duration. Additionally, efficient cost management was achieved through cost control measures, resulting in a significant adjustment of the initial total cost. These findings highlight the importance of implementing comprehensive time and cost control measures to enhance project management efficiency. Overall, the conclusions drawn from this study are in line with established principles of project management and emphasize the significance of optimizing both time and cost parameters for successful project outcomes. The results provide valuable insights for project managers and stakeholders, offering a clear path toward improving project efficiency and achieving desired outcomes. Further research could explore the theoretical and methodological implications of these findings in diverse project management contexts, contributing to a deeper understanding of effective project optimization strategies.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

We extend our appreciation to Universitas Muhammadiyah Aceh for providing access to resources and facilities essential for conducting this research. Their support has been invaluable in the completion of this study.

REFERENCES

Al-Enezi, S. S. S., & Al-Sabah, R. (2023). Comparing Time and Cost Performance of DBB and DB Public Construction Projects in Kuwait. Journal of Engineering Research. https://doi.org/10.1016/j.jer.2023.11.016

Ammar, T., Abdel-Monem, M., & El-Dash, K. (2023). Appropriate Budget Contingency Determination for Construction Projects: State-of-the-Art. Alexandria Engineering Journal, 78, 88-103. https://doi.org/10.1016/j.aej.2023.07.035

Astari, N. M., Subagyo, A. M., & Kusnadi. (2021). Perencanaan manajemen proyek dengan metode CPM (Critical Path Method) dan PERT (Program Evaluation and Review Technique). Jurnal Konstruksia, 13(1), 164-180. https://doi.org/10.22225/pd.4.2.246.13-21

Aziz, R. F. (2014). RPERT: Repetitive-Projects Evaluation and Review Technique. Alexandria Engineering Journal, 53(1), 81-93. https://doi.org/10.1016/j.aej.2013.08.003

Beste, T., & Klakegg, O. J. (2022). Strategic Change Towards Cost-Efficient Public Construction Projects. International Journal of Project Management, 40(4), 372-384. https://doi.org/10.1016/j.ijproman.2022.04.006

Daoud, A. O., El Hefnawy, M., & Wefki, H. (2023). Investigation of Critical Factors Affecting Cost Overruns and Delays in Egyptian Mega Construction Projects. Alexandria Engineering Journal, 83, 326-334. https://doi.org/10.1016/j.aej.2023.10.052

Ketut, N. S. I. (2015). Rencana waktu yang paling mungkin pada proyek konstruksi dengan bantuan program @risk. PADURAKSA: Jurnal Teknik Sipil Universitas Warmadewa, 4(2), 13-21. https://doi.org/10.22225/pd.4.2.246.13-21

Permatasari, T. R., Setyaning, L. B., & Aziz, U. A. (2023). Analisis penjadwalan menggunakan metode Critical Path Method (CPM) pada pembangunan gedung Dindikbud Kabupaten Purworejo. Jurnal Surya Beton, 7(2), 169-175.

Pramesti, H. R., & Listyawan, A. B. (2023). Analisa pengendalian waktu dengan metode Critical Path Method (CPM) pada proyek Pembangunan Pondok Iqro’ Surakarta. Prosiding Seminar Nasional Teknik Sipil, Universitas Muhammadiyah Surakarta, 560-566.

Rahma, K. A., & Kamandang, Z. R. (2023). Analisis penjadwalan proyek Gedung bertingkat menggunakan metode CPM (Critical Path Method) dan PERT (Program Evaluation and Review Technique) (Studi kasus: Proyek Pembangunan tahap I Rumah Sakit Muhammadiyah Gresik). Jurnal Ilmiah Universitas Batanghari Jambi, 23(2), 1275-1279. http://dx.doi.org/10.33087/jiubj.v23i2.4126

Rani, H. A. (2016). Manajemen Proyek Konstruksi. Yogyakarta: Deepublish.

Rani, H. A. (2021). Fungsionalitas Manajemen Proyek dalam Kesuksesan Proyek Konstruksi. Yogyakarta: Deepublish.

Saleh, S. S., Alansari, I. S., Hamiaz, M. K., Ead, W., Tarabishi, R. A., Farouk, M., & Khater, H. A. (2023). I-OPC: An Intelligent Optimal Path Computation System using Critical Path Prediction and Deep Learning for a Time-Sensitive Network. Alexandria Engineering Journal, 84, 138-152. https://doi.org/10.1016/j.aej.2023.10.025

Syammaun, T., Rani, H. A., & Rahmat, F. (2019). Optimalisasi waktu dan biaya Dengan Metode Precedence Diagram Method. Tameh: Journal of Civil Engineering, 8(1), 1-12.

Trietsch, D., & Baker, K. R. (2012). PERT 21: Fitting PERT/CPM for use in the 21st century. International Journal of Project Management, 30(4), 490-502. https://doi.org/10.1016/j.ijproman.2011.09.004

Wicaksono, A. B., & Setiawan, B. (2023). Analisa pengendalian waktu menggunakan metode Critical Path Method (CPM) pada proyek struktur rangka atap baja Stasiun KCIC Karawang. Jurnal Darma Agung, 31(3), 50-58. http://dx.doi.org/10.46930/ojsuda.v31i3.3330

Yang, J. B., & Kao, C. K. (2012). Critical Path Effect-Based Delay Analysis Method for Construction Projects. International Journal of Project Management, 30(3), 385-397. https://doi.org/10.1016/j.ijproman.2011.06.003

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2024. All Rights Reserved.