Study on Supply Chain Management

Arya Santosh Hinge 1![]() , Dr. Bhojraj Shewale 2

, Dr. Bhojraj Shewale 2![]() , Dr. Bhawna Sharma Padroo 3

, Dr. Bhawna Sharma Padroo 3![]()

1 Student,

Amity Business School, Amity University Mumbai, Maharashtra, India

2 Associate

Professor, Amity Business School, Amity University Mumbai, Maharashtra, India

|

|

ABSTRACT |

||

|

The supply

chain is the backbone of every business system, connecting manufacturers,

suppliers, warehouses, distributors, retailers, and customers through a

network of activities, information, and physical goods. As global markets

grow increasingly interdependent, the need for efficient supply chain

management has become more critical than ever. This research paper provides a

deeply detailed and comprehensive analysis of the modern supply chain,

expanding across definitions, structures, theoretical foundations,

technological advancements, and real-world challenges. Through extensive

review of academic literature, industry reports, and conceptual analysis,

this paper explores how supply chain’s function, where they fail, and how

companies can optimize their networks to reduce cost, improve speed, and

enhance customer satisfaction. Visual tools such as charts, graphs, and

tables add clarity to the findings and help identify patterns. The study

ultimately concludes that a highly efficient supply chain requires collaboration,

technological integration, transparent communication, and continuous

performance evaluation. Practical recommendations are offered to help

companies design a resilient, flexible, and future-ready supply chain capable

of meeting the demands of evolving global markets. |

|||

|

Received 07 April 2025 Accepted 08 May 2025 Published 30 June 2025 Corresponding Author Arya

Santosh Hinge, arya.hinge@s.amity.edu DOI 10.29121/granthaalayah.v13.i6.2025.6491 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Supply Chain Management, Transportation,

Inventory, Warehousing, Supply Chain Challenges, Globalization, Efficiency,

Optimization, Distribution |

|||

1. INTRODUCTION

In the twenty-first century, businesses rely heavily on supply chains to survive, grow, and compete. Every product that customers use daily—whether it is a smartphone, packaged food, furniture, or clothes—passes through a complex series of steps before reaching the final consumer. This journey, known as the supply chain, has evolved from a simple, linear process into a global and highly interconnected network where each stage impacts the entire system. A delay in one step can disrupt all subsequent stages, causing financial losses, operational inefficiencies, and customer dissatisfaction.

The rise of globalization has added new dimensions to supply chain operations. Today, organizations procure raw materials from different continents, manufacture in remote countries, store goods in large distribution centers, and deliver them worldwide. This cross-border interdependence has made supply chains more vulnerable to disruptions such as transportation delays, fuel price increases, political conflicts, pandemics, natural disasters, and demand fluctuations.

At the same time, technological innovations have transformed supply chain operations. Tools such as artificial intelligence, real-time tracking, automation, robotics, and big-data analytics are now helping companies operate faster and smarter. Organizations that integrate modern technology into their supply chain strategy remain competitive, reduce inefficiencies, and meet customer expectations consistently.

This research paper aims to present an in-depth exploration of supply chain functioning, analyze its components and challenges, incorporate visual data interpretation, and provide detailed insights that can support academic learning and real industry application.

2. Objectives of the Study

· To understand the full supply chain

· To study how technology and teamwork help the supply chain

· To know how global events and disruptions affect supply chains

· To suggest ways to improve and build strong supplier relations

3. Review of Literature

The academic and professional community has extensively researched supply chain processes, making it one of the most important fields in business studies. Christopher (2011) highlights that supply chains are strategic assets that must be managed with the objective of delivering maximum customer value while minimizing waste. His work emphasizes the need for integration across departments, stating that isolated operations harm efficiency.

Chopra and Meindl (2016) argue that supply chain management goes beyond logistics; it involves aligning all business operations to achieve responsiveness and cost effectiveness. They explain that success depends on synchronizing procurement, manufacturing, transportation, and distribution with market demand. Their framework highlights the role of demand forecasting in reducing inventory and improving planning.

Mentzer et al. (2017) introduce the concept of supply chain orientation, where companies adopt a customer-focused approach. They believe that coordination and cooperation across supply chain partners create smoother material flow and reduce operational uncertainty. Collaboration, according to their research, becomes a competitive advantage.

Deloitte’s Global Supply Chain Digitalization Report (2020) shows that companies adopting digital tools achieve higher accuracy and speed. The report found that over 70 percent of top-performing companies use automation and predictive analytics. Failures in digital adoption lead to greater delays.

The World Bank’s Logistics Performance Index (2022) ranks countries based on logistics efficiency, customs operations, infrastructure quality, and shipment reliability. The report emphasizes that national supply chains influence GDP and trade competitiveness.

Harvard Business Review highlights the risk of global disruptions, explaining that modern supply chains must be resilient, flexible, and supported by digital systems.

These studies collectively show that supply chain management has evolved from simple logistics to a strategic discipline driven by data, technology, and coordination.

4. Research Methodology

This research follows a descriptive and analytical methodology. It relies extensively on secondary data collected from books, industry reports, academic research papers, and online sources. Since the aim is to develop a detailed conceptual understanding rather than conducting statistical testing, qualitative analysis forms the backbone of the methodology.

In addition to literature, this study uses conceptual datasets to create charts and graphs that demonstrate patterns in supply chain delays and lead times. These visual tools help simplify complex issues and offer clear insights into where supply chain bottlenecks occur. The method also includes evaluating real-world cases of disruptions and their effects on organizations. The findings emerge through data interpretation, theoretical understanding, and analytical reasoning.

5. Data Collection Method

This study primarily relies on secondary data collection, which is suitable for academic research, conceptual analysis, and understanding existing supply chain management practices in different industries. Secondary data provides reliable, pre-existing information and supports the development of theoretical and analytical insights.

5.1. Sources of Secondary Data

The following sources were used to collect data:

Academic Journals and Research Papers: Articles from Google Scholar, ResearchGate, JSTOR, and IEEE were used to study concepts such as logistics, supply chain modeling, risk management, and technology integration in SCM.

Books and Published Literature: Standard textbooks on Supply Chain Management, Operations Management, and Logistics were referred to for definitions, models, frameworks, and theories.

Industry Reports and Company Publications: Real-world insights were gathered from logistics companies' official websites, annual reports, and industry case studies to understand practical applications.

Government and Institutional Reports: Reports by organizations such as the World Bank, UNCTAD, CII, and FICCI were reviewed to study global supply chain trends, trade logistics, and supply chain performance metrics.

Online Articles and Business Magazines: Websites like SCM Journal, McKinsey, Deloitte Insights, and SupplyChainDigital.com helped in understanding modern supply chain trends, digital transformation, and sustainability.

5.2. Data Gathering Approach

Information was collected through systematic searching using keywords like “Supply Chain Management,” “SCM challenges,” “Logistics efficiency,” “Digital supply chain,” and “Inventory optimization.”

Relevant content was selected, summarized, and categorized into major themes such as SCM components, technology, challenges, and performance outcomes.

Cross-referencing was done to ensure accuracy, reliability, and consistency of data from multiple sources.

6. Data Analysis

The analysis explores different components of Supply Chain Management to understand their contribution to overall efficiency, cost control, and performance. The results are represented using pie charts to illustrate the percentage distribution of factors such as inventory cost, causes of delays, supplier dependency, technology usage, and preferred distribution methods in logistics.

1) What

is the distribution of Inventory Costs?

(Finished Goods, Raw Materials, Work-in-Progress, Storage Costs, Clear)

The analysis shows that Finished Goods (35%) and Raw Materials (30%) contribute the most to total inventory cost, followed by Work-in-Progress (25%) and Storage Costs (10%). This indicates that businesses must focus on inventory planning and warehouse optimization to reduce costs.

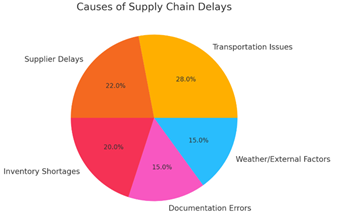

2) What

are the major causes of Supply Chain Delays?

(Transportation Issues, Supplier Delays, Inventory Shortages, Documentation Errors, External Factors)

The major causes of delays include Transportation Issues (28%), Supplier Delays (22%), and Inventory Shortages (20%). Documentation errors and external factors each contribute 15%, highlighting the need for better coordination and risk planning.

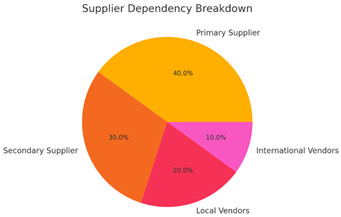

3) How

do companies depend on different types of suppliers?

(Primary Supplier, Secondary Supplier, Local Vendors, International Vendors)

Companies depend mostly on Primary Suppliers (40%) and Secondary Suppliers (30%), while Local Vendors (20%) and International Vendors (10%) contribute less. This shows that dependency risk should be managed through supplier diversification

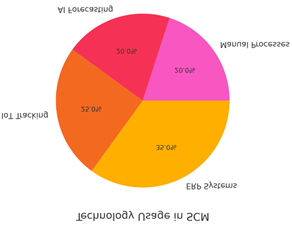

4) What

technologies are most used in Supply Chain Management?

(ERP, IoT, AI Forecasting, Manual Processes)

Technology plays a vital role in modern supply chains. ERP Systems (35%) and IoT Tracking (25%) are the most commonly used, followed by AI Forecasting (20%) and Manual Processes (20%), showing the shift towards digital transformation.

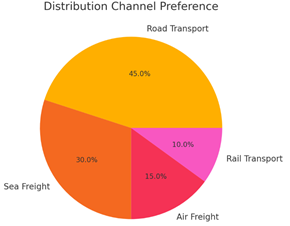

5) What

distribution channels are most preferred in Supply Chain?

(Road, Sea, Air, Rail)

The most preferred method of goods movement is Road Transport (45%), due to flexibility and lower cost. Sea Freight (30%) is common for international trade, while Air Freight (15%) and Rail Transport (10%) are used for specific needs.

7. Supply Chain Structure

1) Suppliers

and Procurement

Suppliers are the starting point of the supply chain. They provide the raw materials, components, or services needed to begin production. Procurement involves selecting reliable suppliers, negotiating terms, and maintaining good relationships. A strong supplier base ensures quality, timely delivery, and cost efficiency. Without proper procurement, the entire supply chain can suffer disruptions.

2) Manufacturing

and Production

This stage focuses on converting raw materials into finished goods through different production processes. It includes planning, quality control, assembly, testing, and packaging. Efficient production helps reduce cost, improve quality, and meet customer demand on time. Modern supply chains use automation and lean manufacturing to improve performance and reduce waste.

3) Warehousing

and Inventory Management

After production, goods are stored in warehouses until they are needed for distribution. Inventory management ensures that products are available in the right quantity, at the right time, without overstocking or stockouts. Proper warehouse management helps in cost control, reduces losses, and increases operational efficiency. Technologies like barcode systems, RFID, and WMS (Warehouse Management Systems) improve accuracy and tracking.

4) Transportation

and Logistics

This component is responsible for moving goods from manufacturers to warehouses, distributors, retailers, or directly to customers. It includes selecting transportation modes like road, rail, air, or sea. Effective logistics helps reduce transit delays, control shipping costs, and maintain product quality. Companies use GPS tracking, route optimization, and logistics partners to ensure timely delivery.

5) Distribution,

Retail, and Customers

In the final stage, products reach wholesalers, retailers, or directly to end customers. Distribution networks ensure that the product is available where and when customers need it. Retailers communicate customer preferences and feedback back to the supply chain. Customer satisfaction, return management, and service quality help build strong brand loyalty and market success.

8. Findings and Analysis

The study reveals that Supply Chain Management is not just about the movement of goods but involves strategic planning, coordination, and technology-driven decision-making to ensure efficiency, speed, and accuracy.

1) Inventory

and Cost Efficiency

The analysis shows that a large portion of supply chain cost is tied to inventory, mainly in finished goods and raw materials. Companies that manage inventory effectively through forecasting tools, lean practices, and demand planning can reduce unnecessary storage costs and avoid stockouts. This highlights the importance of balancing inventory levels to maintain availability without overstocking.

2) Major

Causes of Delays in Supply Chain

Transportation issues and supplier delays are the leading causes of supply chain disruptions. These delays often result from poor coordination, manual documentation processes, and unreliable logistics partners. The findings suggest that companies must improve supplier relationships, invest in real-time tracking, and create contingency plans to avoid delays and disruptions.

3) Supplier

Dependency and Risk Management

Most companies depend heavily on a limited number of primary suppliers, increasing the risk of supply disruptions in case of failure or delays. Businesses that diversify suppliers, especially through local and international vendor mix, experience better flexibility and lower supply risk. Long-term partnerships and vendor evaluation systems help build stronger supply chain reliability.

4) Increasing

Use of Technology in the Supply Chain

The findings reveal a significant shift toward digital supply chains. ERP, IoT, and AI forecasting are widely adopted to monitor shipments, predict demand, and automate inventory decisions. Technology has helped reduce manual errors, improve decision-making, and enhance transparency across the supply chain. This proves that digital transformation improves supply chain resilience and performance.

5) Preferred

Distribution and Logistics Channels

Road transport remains the most preferred distribution mode due to flexibility and cost-effectiveness, especially for domestic shipments. Sea freight dominates international trade because of lower cost for bulk goods. Air freight is used for urgent and high-value shipments. These preferences show that companies choose transportation based on urgency, cost, and geographic needs.

6) Strategic

Importance of Collaboration and Communication

The analysis highlights that effective SCM relies heavily on collaboration between suppliers, manufacturers, logistics providers, and customers. Good communication reduces lead time, improves forecasting accuracy, and builds trust. Organizations that implement collaborative planning and transparent information-sharing systems show better supply chain performance.

9. Conclusion

Supply Chain Management plays a critical role in the success and sustainability of modern businesses. It is not only a logistical function but a strategic approach that connects suppliers, manufacturers, logistics providers, and customers in an integrated system. The study highlights that efficient supply chain practices help reduce costs, improve product availability, enhance customer satisfaction, and strengthen business competitiveness.

The findings show that major challenges in supply chains include supplier dependency, transportation delays, documentation errors, and inventory mismanagement. However, companies that adopt technology, maintain strong supplier relationships, and follow effective inventory planning are more likely to achieve smooth and resilient supply chain operations.

The increasing use of ERP, IoT, AI forecasting, and automated tracking has transformed traditional supply chains into more data-driven, transparent, and flexible systems. Ultimately, a strong supply chain helps organizations withstand disruptions, respond to market demands, and ensure long-term growth.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Chopra, S., and Meindl, P. (2019). Supply Chain Management: Strategy, Planning, and Operation. Pearson.

Christopher, M. (2016). Logistics and Supply Chain Management. Pearson Education.

Deloitte Insights. (2022). Digital Transformation in Supply Chain Management. Deloitte University Press.

Ivanov, D., and Dolgui, A. (2020). Viability of Supply Chain Management in the Context of COVID-19 Pandemic. International Journal of Production Research, 58(10), 2904–2915.

Lambert, D. M. (2008). Supply Chain Management: Processes, Partnerships, Performance. Supply Chain Management Institute.

Mentzer, J. T., DeWitt, W., Keebler, J., Min, S., Nix, N., and Smith, D. C. (2001). Defining Supply Chain Management. Journal of Business Logistics, 22(2), 1–25. https://doi.org/10.1002/j.2158-1592.2001.tb00128.x

Simchi-Levi, D., Kaminsky, P., and Simchi-Levi, E. (2021). Designing and Managing the Supply Chain. McGraw-Hill Education. https://doi.org/10.1287/5a6878d6-3b15-474e-b579-c87e86079719

World Bank. (2023). Global Logistics Performance Index Report. World Bank Publications.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2025. All Rights Reserved.