THE EFFECT OF USING FLY ASH AS A CEMENT SUBSTITUTE ON THE QUALITY OF NICKEL SLAG-BASED PAVING BLOCKS

Sadli Soleman 1![]() , Mufti Amir Sultan 2

, Mufti Amir Sultan 2![]() , Kusnadi

2

, Kusnadi

2![]() , Nurmaiyasa

Marsaoly 2

, Nurmaiyasa

Marsaoly 2![]()

1 Master

of Civil Engineering Program Student, Khairun

University, Ternate, Indonesia

2 Department

of Civil Engineering, Khairun University, Ternate,

Indonesia

|

|

ABSTRACT |

||

|

The Rum Steam

Power Plant (PLTU) uses coal as an energy source. The waste produced from

this process is in the form of solid waste with an amount of ±5% of the total

waste. This solid waste is in the form of bottom ash and fly ash with a

content of 80-90% in the form of bottom ash and the remaining 10-20% in the

form of fly ash. Paving blocks are an important element in urban

infrastructure, used for roads, sidewalks and other public areas. In recent

years, attention to sustainability and the use of environmentally friendly

materials has increased. This research will focus on analyzing the

interaction of these two materials in paving block mixtures, with the aim of

producing construction materials that are more efficient and environmentally

friendly. The research results show that the substitution of cement with fly

ash in paving blocks made from nickel slag has a significant effect on the

mechanical and physical characteristics. The use of fly ash up to 20% shows

relatively good results with a reduction in compressive strength and density

that is not too significant, while the proportion of 30% shows a more drastic

reduction. Therefore, it is recommended to use a maximum proportion of 20%

fly ash as a cement substitute to achieve a balance between strength and

sustainability. |

|||

|

Received 10 December

2024 Accepted 08 January 2025 Published 15 January 2025 Corresponding Author Sadli Soleman, sadlisoleman@pu.go.id DOI 10.29121/granthaalayah.v12.i12.2024.5875 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Fly Ash, Nickel Slaf,

Paving Block |

|||

1. INTRODUCTION

The development of environmentally friendly and sustainable construction materials has received great attention from the construction industry. One of the most significant activities emphasized by engineers and scientists in the construction industry, specifically in the sectors using cement as a binding material, is the exploration of raw materials that can improve the durability of concrete. This effort is in line with the principles of sustainable construction, promoting the development of green concrete and environmentally friendly building practices (Li et al. (2004); Qingren et al. (2004)). The objective behind the concepts of green concrete and construction is to produce sustainable development without damaging natural resources (Suhendro (2014)).

Currently, several industries in North Maluku generate waste that is unused. For instance, in Tidore Kepulauan City, a Steam Power Plant (SPP) operates using coal as its primary energy source, contributing to waste production. The process generates solid waste, making up 5% of the total, consisting of 80-90% bottom ash and 10-20% fly ash Assi et al. (2020). Waste is not managed systematically and is instead disposed of in open areas. One potential approach to handling it is by repurposing it as an additive material in civil engineering applications, such as in concrete mixtures, mortar, bricks, paving blocks, and rigid pavements (Arshad et al. (2021), Cho et al. (2019), Gopalakrishnan (2018), Pangestuti et al. (2024), Rahim et al. (2020), Septiandini et al. (2021), Sultan et al. (2022)).

The Harita Nickel smelter, a nickel ore processing industry on Obi Island, South Halmahera Regency, primarily produces ferronickel and generates about 1 million tons of nickel slag annually. Along with the increase in production, more nickel slag is produced, which can cause the accumulation of nickel slag piles. To prevent the continued increase in nickel slag piles, it is necessary to find alternatives to the use of nickel slag.

The Ministry of Environment and Forestry (KLHK), through Government Regulation No. 22/2021, has officially excluded nine materials from the category of hazardous and toxic waste (B3). According to Attachment XIV of the regulation, these materials include iron and steel slag, nickel slag, mill scale, electric arc furnace (EAF) dust, PS ball, fly ash and bottom ash (FABA) from SPP, spent bleaching earth (SBE), and foundry sand.

The growing pace of development has led to an increasing demand for construction materials. Currently, cement-based building materials, such as paving blocks, are widely used by the public for various applications, such as footpaths, car parks, sidewalks, parking lots, and roads in housing complexes. The increasing need for building materials has led to the need for other raw materials as an alternative to the production of paving blocks. Since 1972, the Center for Settlement Research and Development, under the Ministry of Public Works, has conducted research and promoted the use of waste materials in building production. This initiative supports resource availability, aligns with government construction programs, and addresses industrial challenges. Additionally, utilizing waste materials fosters the growth of small businesses producing building components, adds value for waste managers, and creates new job opportunities.

2. MATERIAL AND METHOD

2.1. LOCATION OF MATERIAL COLLECTION

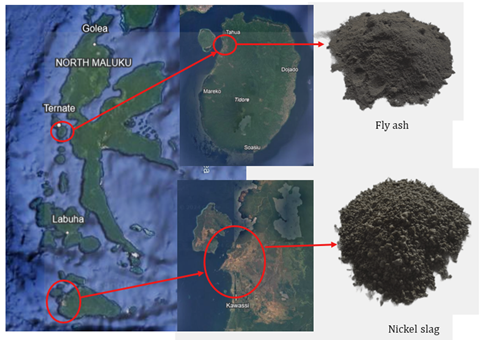

The basic material to form paving blocks using nickel slag is obtained from the nickel processing industry located on Obi Island, which is part of the administrative area of South Halmahera Regency. Fly ash is used as a partial replacement for cement as a binding material obtained from a steam power plant located on Tidore Island, included in the administrative area of Tidore Islands City. Visualization of each material used and the location of its collection are presented in Figure 1.

2.2. TEST OBJECTS

The mortar test specimens are 5x5x5 cm in size and paving blocks are 21x11x6 cm in size. The preparation of test specimens begins with a sieve analysis (ASTM C136-01, 2015), to remove slag particles that do not meet fine aggregate specifications. Subsequently, tests are conducted for mud content, water content, bulk density, and specific gravity in accordance with fine aggregate standards (ASTM C 127-01 & ASTM C 128-01, 2001). Then, the preparation of fly ash with retained sieve analysis No. 200.

The percentage of nickel slag as a substitute for cement used varies from 0% (control test object), 10%, 20%, and 30% based on the comparison of cement weight. The test object is in the form of a cube measuring 5x5x5 cm with a total of 100 pieces, then the test object is soaked in water for 28 days, after 28 days the compressive strength and absorption tests are carried out (ASTM 109 (2009); ASTM C642-97. (1997)).

Figure 1

|

Figure 1 Visualization of Material and Collection Locations in North Maluku |

3. REUSLT AND DISCUSSION

3.1. COMPRESSIVE STRENGTH

The compressive strength test of paving blocks was carried out with a composition of 1:2 and 1:3. The recapitulation of the compressive strength results of paving blocks at the age of 28 days can be seen in Table 1.

Table 1

|

Table 1 Recapitulation of the Compressive Strength Results of Paving blocks with compositions 1:2 and 1:3 |

||||||||||

|

No |

Nickel Slag Variations |

Maximum Load and

Compressive Strength |

Compressive Strength

Difference |

Compressive Strength

Reduction Percentage |

||||||

|

01:02 |

01:03 |

|||||||||

|

(kN) |

(MPa) |

(kN) |

(MPa) |

01:02 |

01:03 |

01:02 |

01:03 |

|||

|

1 |

0% |

55,40 |

22,32 |

38,80 |

15,09 |

- |

- |

- |

- |

|

|

2 |

10% |

42,40 |

17,26 |

25,20 |

10,76 |

4,98 |

4,33 |

22,39% |

28,69% |

|

|

3 |

20% |

29,80 |

12,60 |

25,80 |

7,81 |

9,63 |

5,11 |

43,31% |

48,23% |

|

|

4 |

30% |

24,60 |

9,62 |

13,20 |

5,30 |

12,61 |

9,79 |

56,70% |

64,87% |

|

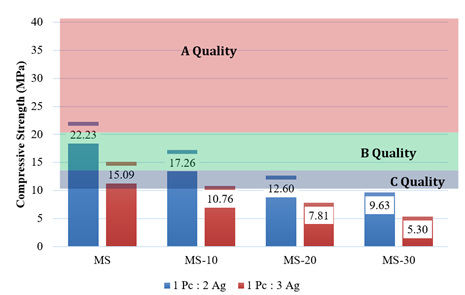

The results of the compressive strength test of paving blocks at the age of 28 days caused a decrease in strength and the average compressive strength obtained was as follows:

· Normal paving block 1:2 is 22.32 MPa, paving block containing 10% fly ash is 17.60 MPa, paving block containing 20% fly ash is 12.60 MPa, and paving block containing 30% fly ash is 9.62 MPa.

· Normal paving block 1:3 is 15.09 MPa, paving block containing 10% fly ash is 10.76 MPa, paving block containing 20% fly ash is 7.81 MPa, and paving block containing 30% fly ash is 5.32 MPa.

As more fly ash is added to the mortar and concrete mixture, the rate of strength gain decreases. Fly ash affects the initial strength gain probably due to the presence of free lime that is still reacting during the curing process. This may be because fly ash provides enough lime needed to react with the pozzolan in the hydration process. More lime inhibits the hydration process but is still sufficient to provide the required design strength (Kumar & Bendapudi (2011)).

3.2. WATER ABSROPTION

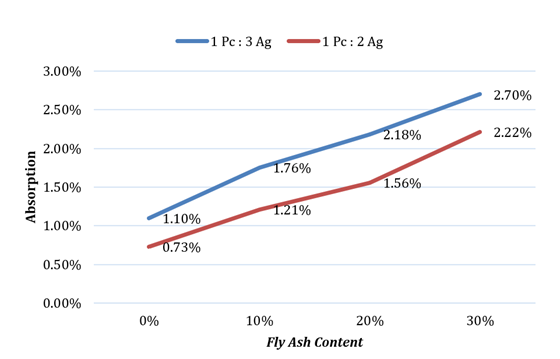

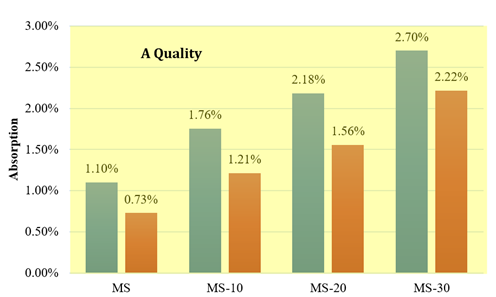

Pengujian penyerapan air pada benda uji paving block dilakukan pada umur 28 hari dengan jumlah Water absorption testing on paving block test specimens was carried out at the age of 28 days with a total of 5 test specimens for 2 compositions 1:2 and 1:3 respectively. The results of the measurement between water absorption and fly ash composition are evident on the test specimens. The results of the paving block absorption test at the age of 28 days can be explained as follows:

· Normal paving block 1:2 is 0.73%, paving block contains 10% fly ash is 1.21%, paving block contains 20% fly ash is 1.56%, and paving block contains 30% fly ash is 2.22%;

· Normal paving block 1:3 is 1.10%, paving block contains 10% fly ash is 1.76%, paving block contains 20% fly ash is 2.18% and paving block contains 30% fly ash is 2.70%.

Figure 2

|

Figure 2 Absorption of Paving Blocks with Fly Ash Variations |

3.3. QUALITY OF PAVING BLOCK

The quality standards for paving blocks refer to the Indonesian National Standard (SNI-03-0691, 1996) as shown in Table 2.

Tabel 2

|

Table 2 Paving Block Class Standards |

|||

|

Quality |

Compressive strength (MPa) |

Maximum average water absorption -rata maksimum |

|

|

Average |

Minimum |

(%) |

|

|

A |

40 |

35 |

3 |

|

B |

20 |

17 |

6 |

|

C |

13 |

12,5 |

8 |

|

D |

10 |

8,5 |

10 |

The quality of paving blocks based on compressive strength and absorption tests is shown in Figure 3 and Figure 4.

Figure 3

|

Figure 3 Paving Block Quality 1:2 and 1:3 Based on Compressive Strength |

Figure 4

|

Figure 4 Quality of Paving Blocks 1:2 and 1:3 Based on Absorption Level |

Based on Figure 3 and Figure 4, the quality of paving blocks can be grouped as follows:

· The composition of a 1:2 ratio of cement binder and nickel slag filler material produces paving blocks (MS) classified as grade B. These paving blocks are used for parking lots, housing complex roads, and car garages.

· The composition of 1:3 with cement binder and nickel slag filler material produces paving blocks (MS) classified as grade C. These paving blocks can be used for light traffic such as footpaths, pedestrians, or sidewalks.

· The composition of 1:2 with 80% cement binder + 20% fly ash (MS-20) and a composition of 1:3 with 90% cement binder and 10% fly ash (MS-10) produces paving blocks of grade D which can be used for road areas with very low traffic such as parks and yards.

· In the composition of 1:2 with 70% cement binder + 30% fly ash (MS-30), the composition of 1:3 with 80% cement binder and 20% fly ash (MS-20) and the composition of 1:3 with 70% cement binder and 30% fly ash (MS-30) paving blocks produced do not comply with the quality requirements set by SNI-03-0691.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

ASTM

109. (2009). Standard Test Method for Compressive

Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). www.astm.org,

ASTM

C 127-01, & ASTM C 128-01. (2001). Standard Test Method for Density,

Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM

International, West Conshohocken, PA, USA, 1-6.

https://doi.org/10.1520/C0127-12.1

ASTM C136-01. (2015). Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International, 04, 1-5. https://doi.org/10.1520/C0136

ASTM

C642-97. (1997). Standard Test Method for Density, Absorption, and Voids

in Hardened Concrete. In Annual Book of ASTM Standards (Issue March).

https://doi.org/10.1520/C0642-13.5.

Arshad,

M. T., Ahmad, S., Khitab, A., & Hanif, A. (2021). Synergistic use of

Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious

Composites. Crystals, 11(915), 2-14. https://doi.org/10.3390/cryst11080915

Assi, A., Bilo, F., Zanoletti, A., Ponti, J., Valsesia, A., La Spina,

R., Zacco, A., & Bontempi, E. (2020). Zero-waste Approach in

Municipal Solid Waste Incineration: Reuse of Bottom Ash to Stabilize Fly Ash.

Journal of Cleaner Production, 245, 1-12.

https://doi.org/10.1016/j.jclepro.2019.118779

Cho, Y. K., Jung, S. H., & Choi, Y. C. (2019).

Effects of Chemical Composition of Fly Ash on Compressive Strength of Fly Ash

Cement Mortar. Construction and Building Materials, 204, 255-264.

https://doi.org/10.1016/j.conbuildmat.2019.01.208

Gopalakrishnan, R. (2018). Strength and Durability of High

Volume Fly Ash Concrete in Severe

Environment. International Journal of Civil

Engineering and Technology (IJCIET), 9(11), 718-727.

Kumar, S. C., & Bendapudi, B. (2011).

Contribution of Fly Ash to the Properties of Mortar and Concrete.

International Journal of Earth Sciences and

Engineering, 6, 1017-1023.

Li, Z., Ding, Z., & Zhang, Y. (2004). Development Of Sustainable Cementitious Materials. International Workshop on Sustainable Development and Concrete Technology, 55-76.

Pangestuti, E. K., Julianto, E. N., Ayu Hapsari, R. N., Sholahudin, F., Aida, N., Ardiasnyah, D., Bagaskara, P., & Heriyanto, F. R. (2024). Utilization of Fly Ash and Bottom Ash as a Mixture for Making Paving Blocks. IOP Conference Series: Earth and Environmental Science, 1381(1). https://doi.org/10.1088/1755-1315/1381/1/012015

Qingren, W., Qiongyu, H., Hongguang,

L., & Yongjun, Z. (2004). Research On Using

Waste Sludge Of Smelting

Lead And Zinc To Sinter Cement Clinker. International Workshop on Sustainable Development and Concrete Technology, 171-191.

Rahim, I. R., Caronge,

M. A., & Amqhaar, M. M. (2020). Effect of Fly Ash as

Partial Replacement of Cement in Aggressive Environment. In International Association of Lowland Technology (Vol. 22,

Issue 2).

SNI-03-0691. (1996). Bata beton (Paving Block). In Standar Nasional Indonesia. Badan Standardisasi Nasional.

Septiandini, E., Widiasanti, I., Pamungkas, C. A., Putri, A.

S. S., Mulyono, T., & Abdul, N. Z. P. (2021). Compressive Strength

of Pervious Concrete Paving Blocks for Pavement With the Addition of Fly Ash.

IOP Conference Series: Materials Science and Engineering, 1098(2), 1-7.

https://doi.org/10.1088/1757-899x/1098/2/022046

Suhendro, B. (2014). Toward Green Concrete for Better

Sustainable Environment. Procedia Engineering, 95, 305-320.

https://doi.org/10.1016/j.proeng.2014.12.190

Sultan, M. A., Kusnadi, K., & Adingku, J. (2022). Determination of Geopolymer Mortar Characterization Using Fly Ash and Pumice Sand. International Journal of GEOMATE, 23(100), 86-94. https://doi.org/10.21660/2022.100.3630

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2024. All Rights Reserved.