RESEARCH FOR BUILDING INTELLIGENT DIGITAL CONTROL CONTAIN IN VIETNAM AND A MATHEMATICAL FORMULA TO CALCULATE THE CONVEYOR SYSTEM LENGTH

1 Postgraduate,

Business Administration, Foreign Trade University, Hanoi, Viet Nam

|

|

ABSTRACT |

||

|

This article investigates a novel approach to converting container seaports into digital transformations on old port platforms to maximize land area for production. This model is not only suitable for Vietnam but is also applicable to numerous container seaports worldwide, ranging from small to large, including those considered smart. According to VCCI (2022), digital technology can unlock the potential of seaports. Despite the information provided by VCCI indicating that the port system in Vietnam extends across the country, it has not received adequate investment in IT applications. Royal Haskoning DHV, a leading global technical consulting group in the fields of industry, seaports, maritime, and technical infrastructure, aims to steer Vietnam's seaports, including container seaports, towards a greener and smarter direction. The first step in this transformation is supply chain integration. According to their perspective, improvements in transport links promise to enhance efficiency and reduce congestion in the port area. Scheduled timings for trucks, setting timelines for loading and unloading goods, and the digitization of processes enable managers to interact with the supply chain in real-time. Valdés Figueroa & Pérez (2020) suggests that the future of logistics digitization involves a shift from individual developments to logistics intelligence, in the article titled “Digital transformation in Latin American and Caribbean logistics”. In terms of technology, planning layers, industry guidelines, and the foundation of programs, plans, and projects must be appropriately anchored at higher political levels. This alignment will enable the synchronization of industry rules and regulations with the logistics landscape, promoting the digitization of processes to reduce inefficiencies, cost overruns, and negative externalities. This, in turn, enhances productivity and competitiveness, fostering economic growth and social inclusion among populations both now and in the future. The study

introduces a new idea for efficiently incorporating digital technology into

the reform of container seaports, making them smarter and stimulating

production. This, in turn, contributes to the economic growth of the region

and the country as a whole. |

|||

|

Received 25 April

2024 Accepted 30 May 2024 Published 04 July 2024 Corresponding Author Nguyen Le

Hai Khanh, khanhlhnguyen@gmail.com DOI 10.29121/granthaalayah.v12.i6.2024.5670 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Numerical Control, Container Seaport,

Smart Seaport, Conveyor System, Container Scanner, Container Rotating

Platform |

|||

1. INTRODUCTION

The Ocean Economy is an essential contributor to the GDP of coastal countries, with seaports, including container seaports, serving as hubs for terminal activities in the commodity production cycle. Moreover, seaports not only bring economic benefits but also play a role in addressing national security and territorial integrity concerns for a nation. This aligns with considerations of a political, economic, and technical nature, including the importance of military seaports.

In their 2021 paper titled "Revisiting port sustainability as a foundation for the implementation of the United Nations Sustainable Development Goals (UN SDGs)" Alamoush et al. (2021), presented a research framework that categorizes actions and provides measures and plans to effectively implement policies in container ports. Using a document review and commentary method, they concluded that the relationship between the sustainability of container ports and the United Nations' Sustainable Development Goals closely aligns. The sustainability of container seaports encompasses actions and measures both inside and outside the port, extending to rail and road infrastructure.

Karaś (2020) discussed technological innovation, particularly digital control innovation at container seaports, in the article titled "Smart Port as a Key to the Future Development of Modern Ports". This innovation presents an opportunity to establish smart container seaports. However, determining which technology to use and how to implement it remains a significant challenge. Consequently, it can be concluded that the continuous introduction and development of the concept of smart seaports are inevitable trends that will influence the development direction of current container seaports.

Seaport trade involves various parties, including domestic and foreign business consumers, marine operators, and others. To make the transportation of goods smarter and more sustainable, the infrastructure of seaports needs to be adjusted, upgraded, and rebuilt for transshipment operations both on ships and on land. This, in turn, creates conditions for the convergence of road traffic and maritime systems.

In the present day, the development of seaports, including smart container seaports, emphasizes their role in responding to additional traffic and the complexity of freight distribution through the transport network. Digital technology, automation, IoT, cloud computing, numerical control, and other advancements are gradually replacing human labor in various aspects of social life—from everyday purchases and e-commerce transactions to areas requiring precision and caution, such as healthcare and education. This marks the emergence of a new concept, the "Smart Container Seaport”.

The container seaport can handle the transshipment of heavy and large goods through large container ships that are impractical for transport by road. Large seaports serve as focal points and transshipment hubs for maritime activities. On the other hand, smaller ports, particularly those well-connected to road and rail transport systems, serve as sources of goods through short-term sea transportation using inland waterway transport.

Therefore, constructing a smart container seaport would be a strategic move towards achieving sustainable development and making a significant contribution to the international trade development for businesses and the entire country. Simultaneously, it is crucial to capitalize on Vietnam's coastline, which spans approximately 3260 km.

2. LITERATURE REVIEW

Mudronja et al. (2020), in their article titled "Seaports and Economic Growth: Panel Data Analysis of EU Port Regions", make a clear statement that container seaports play a crucial role in the development of regional economies, as the activities of seaports have positive effects on the economy.

The successful operation of container seaports relies on the application of new scientific technologies and a greater emphasis on innovation. The future use of such technologies is expected to reduce costs, streamline business operations, enhance transparency, attract new business entities, and give rise to new business forms.

Presently, various factors indicate that container seaports exert a significant impact on the economic growth of port areas. However, it is imperative to consider other factors influencing regional economic growth, such as investments in research and development (R&D) and human resources.

These factors are often underestimated, as they are

intricately linked to investments in infrastructure and superstructure at

container seaports. Therefore, having a specific guide is essential to redirect

towards a more useful path, optimizing labor

productivity, and increasing economic efficiency at container seaports.

This study introduces a research model that applies numerical control to production activities in container seaports, incorporating a high-tech element into operations—the conveyor system for containers. Additionally, the researcher provides a mathematical formula to calculate the required length for constructing and installing the conveyor belt, aiming to optimize investment and accelerate production in container seaports.

The final section of this paper proposes essential elements for establishing a digitally controlled intelligent container seaport and outlines the benefits of the proposed model.

Douaioui et al. (2018) focus on defining the conceptual purpose of smart logistics at seaports, in the article titled “Smart port: Design and perspectives”. They delve into the main challenges that hinder the feasibility and competition when applying high technologies to digitally controlled intelligent container seaports. The article further provides a model of the concept of a smart container port by identifying the main pillars in the port, such as infrastructure and superstructure elements, and stating the essential components necessary for the formation of those pillars.

The strength of this research model lies in enhancing the efficiency of production work at container seaports while contributing to the economic development of regions with container seaports. Furthermore, the proposed model aims to address several longstanding issues in container seaports that remain unresolved.

However, the proposed model also has its weaknesses. As this represents a completely new direction in the country and worldwide, there are no specific examples or evidence to draw from. The applications of proposed digital control technology in seaports are still in the research and proposal stage, making it challenging to determine the cost and the timeline for development and implementation."

3. Research methodology

In this article, the researcher will employ various scientific research methods, encompassing methodology, data collection, mathematical analysis, and practical research approaches such as surveys, observations, experiments, and analytical methods to summarize experiences. Additionally, theoretical research methods, including analytical and synthesis approaches, as well as logical methods, will be applied.

4. Findings and discussion

Boullauazan et al. (2023) assert that congestion in container seaport areas is increasingly prevalent, in the article titled “Developing and demonstrating a maturity model for smart ports”. Consequently, container seaports must transition to a more efficient, greener, and reliable mode of goods transportation. Simultaneously, there is a growing need for increased attention to sustainable development activities within seaport areas. Recognizing this, the importance of smart seaports becomes evident. The initial step involves formulating a new specific strategy for smart seaports, including smart container seaports, through thorough research and development. This is coupled with the implementation of a management policy for the seaport and a clear and comprehensive roadmap designed to enhance the port community.

1)

Proposing

a digitally controlled intelligent container seaport model

Digital control, although a small component within the broader field of digital technology, plays a crucial role in ushering people into the digital age. The reason behind labelling the proposed model for container seaports as a numerically controlled container seaport is that the majority of production activities within the container seaport utilize digital platforms to control equipment and machinery. When manually operated by humans, it is termed manual control, while automation refers to operation facilitated by machinery.

Despite the application of numerical control in the proposed container seaport model, there are still certain aspects that necessitate human management and operation. Hence, the model is commonly referred to as a digitally controlled intelligent container seaport. The researcher aims to provide an overview model for a digitally controlled intelligent container seaport as follows: [continue with the details of the overview model.

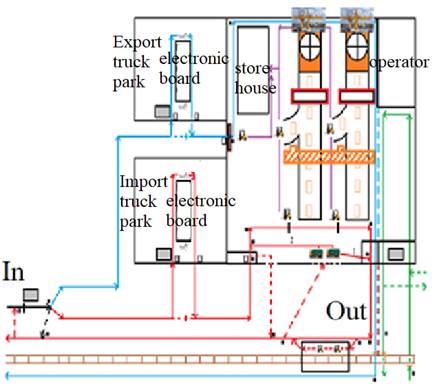

Figure 1

|

Figure 1 Model of Intelligent Container Seaport with Numerical Control |

The following is a general description of the proposed operation of the intelligent container port with numerical control.

The smart container seaport with numerical control, as proposed by the researcher, comprises two main sections for production activities: the seaport area and the container truck yard. Container trucks involved in import/export activities at the container seaport enter through a guard station. Here, information about the list of incoming ships and the expected arrival times of the ships will be displayed to guide them in the right direction.

As per the model proposed above, export cars will follow the blue line, while imported cars will follow the red line. Both vehicles proceed straight if they receive information that their ship has arrived or their container is already waiting in the container yard. Otherwise, both vehicles enter the container yard to wait and incur an hourly fee.

Two operational forms exist for container ships and trucks: export and import. The researcher will analyze and explain the workings of each in the model.

Regarding export behavior: the car follows the blue line to the seaport area. If the ship is ready, it proceeds directly to the port crane area; if not, the car heads to the container truck station to wait, incurring an hourly yard fee. Subsequently, the car exits following the blue line.

In the case of importing, the container is lowered from

the ship by the crane system at the wharf onto the proposed conveyor system.

This system comprises three main parts: a rotating platform ![]() ,

a flexible conveyor belt

,

a flexible conveyor belt ![]() ,

and a fixed conveyor belt

,

and a fixed conveyor belt ![]()

The rotating platform serves the primary function of receiving the container from the crane, rotating it from a horizontal to a vertical position, and placing it onto the conveyor system. This facilitates the mini forklift in conveniently loading the container at the end of the conveyor belt for subsequent placement onto the container truck. A numerical control camera is mounted on the front swivel side to monitor and track the loading and unloading operations on the bridge.

Once the container is brought down to the rotating

platform and rotated from a horizontal to a vertical orientation, it proceeds

to the flexible conveyor belt. The flexible conveyor belt is tasked with

assisting the rotating platform in unloading and transporting containers into

the yard.

Containers then proceed onto a fixed conveyor belt, a

conveyor belt fixed on the ground responsible solely for transporting and

moving containers from the wharf area to the container yard. Near the wharf

section of the fixed conveyor belt, there is a container scanner tasked with

inspecting the goods within the container without tampering with the container

seal ![]() .

If the inspection results are satisfactory, a message is displayed for the

container truck to retrieve the goods from the yard.

.

If the inspection results are satisfactory, a message is displayed for the

container truck to retrieve the goods from the yard.

The designated container is guided to the side by the

conveyor system, where a forklift awaits to transport it into the warehouse for

a direct inspection of the contents. If the container passes inspection, it

proceeds straight to the end of the conveyor belt. The mini forklift remains

stationed there, and upon the arrival of the container truck, it loads the

goods onto the truck. The area also features a canal or overhead walkway ![]() for

pedestrians wishing to enter the production area.

for

pedestrians wishing to enter the production area.

Containers, starting from the moment they pass through the container scanner and are confirmed as acceptable, will receive a notification to proceed to the container yard, allowing vehicles to promptly arrive for cargo pickup. The mathematical formula for calculating the time it takes for the truck to travel from the parking lot to pick up the container at the precise arrival time will be provided below.

The operator is situated separately from the production area in the seaport and has a distinct route, indicated by the green line, for travel to and from the seaport using the container truck. The location of the warehouse and the operator is entirely dependent on the entry and exit of trucks and the import/export parking lot.

Containers loaded by rail will be transported to the port by the port's container truck. For exports, the port's vehicle will collect goods from the train, then enter the lane for external export vehicles to access the port and commence export activities.

Regarding the import process, the vehicle will arrive to pick up the container at the end of the conveyor belt upon notification by the operator and proceed to the yard for transshipment onto the train.

2) Propose

a mathematical formula to calculate the length of the conveyor belt

The researcher proposes a mathematical formula to calculate the design length of the fixed conveyor belt from the scanner to the container yard in the port, thereby determining the optimal time for the truck to arrive at the yard when the container, which has been prepared by the mini forklift, is ready to be loaded onto the vehicle. Relative errors may occur when:

Container trucks enter faster or slower than the scheduled time.

Containers on the way to the container yard, or the conveyor system itself, encounter technical problems.

The mini forklift operating in the yard has an accident and must wait for an alternative plan.

All external factors affecting the truck or container are assumed to be zero by the researcher.

t truck = T +

(A+B-x-y-z-k-n)/v2

t container =

x/v1

Setting the length of the conveyor belt so that the truck and

the container meet at the right time, we have:

t truck = t

container

From there,

we will have the expression x =

[(A+B-y-z-k-n+v2.T).v1]/(v1+v2), where:

x: is the

distance of the container going from the scanner to the yard

v1: is the

speed of the container on the conveyor

v2: is the

speed of the container truck

T: is the

time it takes the container truck to go from the yard to the entrance

A, B: is the width and length of the port

y: is the

distance from the yard location at the end of the conveyor belt to the line

separating individual vehicles and container trucks at the exit gate of the

port

n: is the

width of the individual car gate

z: is the

length from the end of the flexible conveyor belt to the scanner

k: is the

width of the bottom part of gantry crane, base crane

Looking at the above

equation, we can make the comment: v1, v2, the larger T, the longer x is and

can be changed. Since v2, T of the vehicle will be variable and unpredictable

(we can only estimate a certain amount of weight), so v1 of the carousel will

be a factor that the manager can actively adjust, but the condition of v1 is

v1<v2.B/(A-n-y-z-k+v2.T).

Because v1 is designed to move faster when carrying containers, the length of the conveyor belt is longer to improve the likelihood of synchronizing the arrival of containers and trucks at the port's entrance and exit gates. However, it must satisfy the condition 𝑥 < 𝐵. Since 𝑇 varies only for a short period (less than 10-20 minutes), 𝑥 will not change much when 𝑇 changes. Additionally, although 𝑦 changes, it always remains less than 𝐴 and does not significantly affect 𝑥. Therefore, averaging 𝑥(using values of 𝑥 up to three decimal places to calculate the average) for all conveyor belts would be the most feasible and efficient option for the vehicles traveling from the parking lot to the entrance. This will prioritize two key issues that need to be addressed.

3) Proposing

the necessary and sufficient factors/conditions for building a digitally

controlled intelligent container seaport

In their 2014 article, "Dome over the Gdynia Seaport Building" Godycki-Ćwirko et al. (2014) provided both high-tech and technical conditions that offer a clearer perspective on the feasible factors for building a smart container seaport. Through the research process, the researcher proposes several necessary and sufficient factors and conditions to enhance the feasibility of constructing a digitally controlled intelligent container seaport, specifically as follows:

Geology: A digitally controlled intelligent container seaport should be built in coastal areas with deep water depth or renovated in existing coastal port areas, depending on the specific requirements of different types of container ships to facilitate the entry and exit of cargo ships. Additionally, the port construction area must have hard ground to prevent erosion.

Working Procedures: Processes must be simplified as much as possible through online forms. Additionally, building direction signs, inspection doors, and automatic toll stations within the port area will make it convenient for container drivers to complete a closed cycle in the port with minimal delays.

Furthermore, there should be a connection between trucks, shipowners, railways, and seaports to handle administrative procedures through a Big Data database, along with accelerating communication methods between related parties.

Additionally, there should be a connection between trucks, shipowners, railways, and seaports to handle administrative procedures through a Big Data database, while also accelerating communication methods between related parties.

Flexibility and Efficiency: Reducing the waiting time for ships and vehicles during the loading and unloading process can be achieved through coordinated management by the port operator. From the initial loading of the container onto the conveyor belt to the ship's departure, the process should run smoothly. The port operator needs to have timely and efficient plans, along with an established electronic technical team to handle emergencies. Appropriate measures should be in place to address accidents or unexpected incidents involving machinery and equipment used in port operations. Additionally, the operator must quickly resolve and adjust to any abnormal changes affecting the port's production.

Safety: Ensuring the separation of pedestrians, private vehicles, and container trucks is crucial. The passageways in the port and the working areas for loading and unloading at the yard should be distinct from the traffic routes of personal vehicles. Traffic routes within the port should be arranged as one-way lanes for import and export trucks to pick up or drop off cargo. The entry lanes for trucks should be used only when there is a request from the truck rental company, thereby limiting intersection points between traffic routes to the minimum possible level.

Connectivity: The port needs to collaborate with the provincial and local Departments of Transport to provide the most optimal directions for container trucks entering and leaving the province. Additionally, container ships should coordinate closely with seaports and customs in both exporting and importing countries through a computer network platform and satellite internet. This cooperation will facilitate efficient and quick handling of operations and documentation procedures, ensuring the smooth transshipment of goods

Moreover, the Maritime Administration should propose the development of a common Big Data software platform for seaport countries to enhance economic cooperation. This initiative will facilitate the rapid execution of cross-border administrative procedures and allow ports to regularly update information on port status and other relevant data. This information can then be effectively gathered and managed by the Maritime Department, especially in maneuvering ships into the harbor.

Technology: A highly specialized technical team is essential to ensure the smooth operation of numerical control cranes, automatic turntables, conveyor systems, container scanners, notification systems at the truck yard for import/export activities, and automatic toll stations. This will help prevent prolonged technical issues that could impact port operations, decrease labor productivity, and reduce economic efficiency. Continuous upgrades, conversions, and the development of software and hardware to meet the requirements of the proposed numerical control model are crucial. Additionally, the security team at the port's entrance gates must be trained in electronic technology to address problems arising at toll booths and bulletin boards promptly.

Human Factor: The port must have a reasonable allocation of labor resources to respond immediately when a container ship arrives for import or export activities. Implementing a shift work system (at least three shifts) will ensure continuous operation. Specific notices and preparations must be in place to accommodate container trucks entering the yard to pick up goods. The security personnel at the port entrance should have a certain level of proficiency in information technology and machinery to handle unexpected situations at automatic toll booths efficiently.

Economical: It is necessary to find a new direction that integrates digital control into production activities at seaports at a reasonable cost for investors and container import/export businesses.

Sustainable Development Goals: The port should aim to develop as a smart and sustainable seaport, focusing on three criteria: Commitment and Readiness, Action and Implementation, and Effectiveness and Efficiency. Each criterion should have specific goals and sub-criteria. Notably, the Action and Implementation criteria should account for more than 50% of the overall emphasis, reflecting their importance in achieving the port's sustainable development goals.

4) Some

benefits of this proposed model

The proposed model of a smart container seaport with numerical control offers numerous advantages, not only in terms of economic development and effective management of human resources and equipment but also in several other positive aspects worth considering:

Improved Labor Productivity and Operational Efficiency: With most loading and unloading tasks now automated, labor productivity and operational efficiency in container seaports will significantly increase.

Congestion Relief: The model addresses the issue of ship and container congestion in the seaport area, ensuring smoother operations.

Enhanced Security: By checking all goods in containers equally, as opposed to random checks, the model improves security and reduces the risk of insecurity at seaports.

Synchronization of Operations: The use of a common Big Data platform facilitates faster, more convenient, and synchronized operations of ships, container trucks, and trains in the seaport area.

Reduced Human Labor in Hazardous Tasks: By decreasing the reliance on human power for container loading and unloading, the model enhances safety in the container seaport area.

5. Conclusion

The container seaport is a crucial gateway for countries with coastlines that engage in global trade. Vietnam has a unique advantage with its extensive coastline stretching from the North to the South, which is a significant factor in developing increasingly intelligent seaports, thereby boosting the nation's economy.

Petering (2011), in his article "Decision Support for Yard Capacity, Fleet Composition, Truck Substitutability, and Scalability Issues at Seaport Container Terminals" emphasized the necessity and urgency of applying high technologies to address long-standing issues in container seaports. Solving these problems requires a practical and feasible approach to make the development of smart container seaports more efficient than before.

This study proposes a positive direction for the synchronous integration of modern scientific technologies into production activities, offering a new way to maximize labor productivity and resolve many existing issues in current container seaports.

In their 2020 article "Integrated Ocean Management for a Sustainable Ocean Economy" Winther et al. (2020). highlighted the importance of the marine economy, including the economy in container seaports, in achieving the United Nations’ sustainable development goals. Despite the challenges and shortcomings in implementing governance frameworks, a holistic approach to addressing all existing problems in container seaports is crucial for developing a sustainable ocean economy. Digitally controlled container seaports will pioneer the digital transformation of seaports, advancing toward a sustainable ocean economy.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Alamoush, A. S., Ballini, F., & Ölçer, A. I. (2021). Revisiting Port Sustainability as a Foundation for the Implementation of the United Nations Sustainable Development Goals (UN SDGs). Journal of Shipping and Trade, 6, 1-40. https://doi.org/10.1186/s41072-021-00101-6

Boullauazan, Y., Sys, C., & Vanelslander, T. (2023). Developing and Demonstrating a Maturity Model for Smart Ports. Maritime Policy & Management, 50(4), 447-465. https://doi.org/10.1080/03088839.2022.2074161

Douaioui, K., Fri, M., & Mabrouki, C. (2018, April). Smart Port: Design and Perspectives. In 2018 4th International Conference on Logistics Operations Management (GOL) (pp. 1-6). IEEE. https://doi.org/10.1109/GOL.2018.8378099

Godycki-Ćwirko, T., Nagrodzka-Godycka, K., & Piotrkowski, P. (2014). Dome Over the Gdynia Seaport Building. Archives of Civil Engineering, 60(2), 223-239. https://doi.org/10.2478/ace-2014-0015

Karaś, A. (2020). Smart Port as a Key to the Future Development of Modern Ports. TransNav: International Journal on Marine Navigation and Safety of Sea Transportation, 14(1). https://doi.org/10.12716/1001.14.01.01

Mudronja, G., Jugović, A., & Škalamera-Alilović, D. (2020). Seaports and Economic Growth: Panel Data Analysis of EU Port Regions. Journal of Marine Science and Engineering, 8(12), 1017. https://doi.org/10.3390/jmse8121017

Petering, M. E. (2011). Decision Support for Yard Capacity, Fleet Composition, Truck Substitutability, and Scalability Issues at Seaport Container Terminals. Transportation Research Part E: Logistics and Transportation Review, 47(1), 85-103. https://doi.org/10.1016/j.tre.2010.07.007

VCCI (2022). Advancing Digital Transformation in Seaport Industry. Vietnam: Vietnam Business Forum.

Valdés Figueroa, L., & Pérez, G. (2020). Digital Transformation in Latin American and Caribbean logistics.

Winther, J. G., Dai, M., Rist, T., Hoel, A. H., Li, Y., Trice, A., ... & Whitehouse, S. (2020). Integrated Ocean Management for a Sustainable Ocean Economy. Nature Ecology & Evolution, 4(11), 1451-1458. https://doi.org/10.1038/s41559-020-1259-6

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2024. All Rights Reserved.