BEHAVIOR OF PHYSICAL AND DENSITY PROPERTIES OF SOFT SOIL STABILIZED WITH NICKEL SLAG

Abdul Gaus 1![]() , Ichsan Rauf 1, Komang Arya Utama 2,

M. Taufiq YS 1, Linda 1

, Ichsan Rauf 1, Komang Arya Utama 2,

M. Taufiq YS 1, Linda 1

1 Department

of Civil Engineering, University of Khairun, Ternate,

Indonesia

2 Department

of Civil Engineering, State University of Gorontalo, Gorontalo, Indonesia

|

|

ABSTRACT |

||

|

Soft soils have become a significant

challenge in geotechnical engineering, due to their low bearing capacity and

susceptibility to deformation. Chemical stabilization using nickel slag is an

alternative solution and is considered more environmentally friendly. This

article focuses on the utilization of nickel slag as a binder material aimed

at behavior of physical and mechanical properties of soft soil stabilized

with nickel slag soft soil. The nickel slag was carried out with variations

of 3%, 6%, 9% and 12% by weight of soil. All the test using ASTM procedure in

order to gain physical and mechanical value. The results of this study showed

that plasticity index decrease with the increasing of slag nickel

concentration, where it is an indication of a change in soil consistency,

shifting from initially soft to now medium. Futher,

the optimum dry density (d-opt) value of the original soil used was

1.09 gr/cm3, while the optimum dry density (d) values at 3%, 6%, 9%

and 12% nickel slag addition were 1.12 gr/cm3; 1.15 gr/cm3; 1.19 gr/cm3 and

1.22 gr/cm3, respectively. These results show that the presence of nickel

slag can increase influence the physical and density properties of soft soil,

which indicates that nickel slag has the potential to be used as a stabilization

material in soft soil. |

|||

|

Received 21 December

2023 Accepted 20 January

2024 Published 06 February 2024 Corresponding Author Abdul Gaus, gaussmuhammad@gmail.com DOI 10.29121/granthaalayah.v12.i1.2024.5485 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Soil Stabilization, Soft Soil, Nickel

Slag |

|||

1. INTRODUCTION

Earthwork is an important part of civil construction, such as roads, bridges, weirs, buildings, etc. However, in reality not all soils have mechanical properties capable of providing a safe base for infrastructure. The inherent variability in soil characteristics necessitates the development of ground improvement techniques to guarantee the safety and service life of construction. Among these techniques, chemical soil stabilization has emerged as a key solution, harnessing the power of chemical additives to alter the properties of soils and make them suitable for construction purposes.

Soil stability is an important factor in determining the overall performance and safety of a structure. Unstable soils can cause a variety of problems, ranging from differential settlement and structural damage to reduced bearing capacity and increased risk of foundation failure Das (2019). Conventional soil stabilization methods, such as mechanical compaction and soil replacement, have limitations, especially when dealing with problematic soil types such as expansive clay or loose sand Amhadi & Assaf (2019). Chemical soil stabilization, on the other hand, presents a more effective approach and provides significant leverage in addressing the challenges of improving soil properties in a controlled manner.

In principle, chemical stabilization efforts can reduce soil pores through the bonding of binder particles with soil material Firoozi et al. (2017). The volume of pores in the soil decreases in line with the drying process which results in reduced pore numbers and soil permeability values. This is why chemical stabilization efforts have a higher and significant resistance to increasing soil bearing capacity Mariri et al. (2019). This soil cementation mechanism will then increase the density and strength of the soil in receiving loads, thus meeting technical requirements, especially in road foundation construction. Dodson (1990) explains that the mechanism of increasing soil bearing capacity occurs through pozzolanic reactions and hydration, which are well-known reactions among calcium hydroxide alumina and/or silica and water. The final products of these reactions depend on the content of the available silica and alumina, which can be calcium aluminate hydrate, calcium silicate hydrate and calcium aluminoslica hydrate.

Cement and lime are the most commonly used materials as stabilization materials, however, the use of these two materials has a major impact on the environment because the manufacturing process produces a very large amount of carbon gas. Therefore, the development of material engineering currently leads to the use of natural materials or industrial waste that is pozzolanic in nature as an alternative stabilization material in soft soil.

The ASTM 593-82 standard classifies pozzolanic materials based on their source, namely: (a) natural pozzolan is a material derived from volcanic materials containing active silica, such as: trass, pumice, perlite, and (b) artificial pozzolan which is a material derived from combustion products, such as: fly ash, sediment ash, slag, etc. Soil stabilization engineering that utilizes pozzolan has been widely done, such as: utilization of natural pozzolan in the form of trass Komang et al. (2022), in the form of overboulder and zeolite Harianto et al. (2020). Furthermore, the utilization of artificial pozzolan has been presented by several researches, such as: the utilization of button asphalt waste Rauf et al. (2020), the use of coal bottom ash Navagire et al. (2022).

The increasing need for nickel has encouraged the development of the nickel industry in various countries, including Indonesia. North Maluku is one of the provinces with the second largest nickel reserves in Indonesia. Nickel processing produces by-products such as slag, fly ash, sedimentary ash and nickel sludge. These by-products have great potential to be used as stabilization material in soft soil, because they have pozzolanic properties. The results of XRF and XRD testing on nickel slag material from Obi Island show that this nickel slag material has a mineral content of SiO2 of 44.89%, Fe2O3 of 25.11%, MgO of 20.27% and CaO of 3.34% Rauf et al. (2023). The mineralogical content dominated by silica indicates that this material is pozzolanic, so that nickel slag can be used as a stabilization material for the soft soil.

This research aims to analyze the effect of nickel slag used as stabilization material on clay soil. The effect of nickel slag variation as stabilization material is based on the change of clay density value while still considering the value of its physical characteristics.

2. MATERIAL AND METHODS

2.1. Materials Quarry

The soil samples used in this study are soft clay

soils taken from Subaim village, which is

administratively located in East Halmahera Regency, North Maluku Province. This

is based on the mapping of the distribution of problematic clay soils that has

been carried out by the Indonesian Ministry

of Energy and Mineral Resources. Meanwhile, the nickel slag material that will

be used as stabilization material, it is obtained from the nickel

processing industry where located on the island of Obi

which is included in the administrative area of South Halmahera Regency. The

visualization of each materials used and their quarry presented in Figure 1.

Figure 1

|

Figure 1 Visualization of Samples and Materials Quarry in North Maluku. |

2.2. Samples Preparation

The initial stage of sample preparation is the drying

process where the clay and nickel slag are dried under the sun. This is done to

ensure that there is no change in the chemical structure of the soil material

and nickel slag due to excessive heating. For uniformity of material granules,

the soil used is soil that has been filtered and passed the No. 40 sieve. The

nickel slag in the form of granules is mashed using a grinding machine and

filtered using a No. 200 sieve to be used as a stabilizing material, because

the size of the gradation greatly affects

the reactivation of the binder material Janz & Johansson (2002).

In this study, the examination of the physical

characteristics of clay soil was carried out using tests which included: Water

Content Test with ASTM D-2216 method, Specific Weight Test with ASTM D 854-58

method, Atterberg Limits Test with ASTM D 4318-95 method, Grain Analysis Test

with ASTM 422-72 and ASTM D 1140-54 methods. Meanwhile, The Soil Density Test

uses the standard proctor method which refers to ASTM D1557. The compaction

technique plays a crucial role in affecting the gravimetric and volumetric characteristics

of a remoulded specimen, such as mass density and porosity. These structural

variances can lead to distinctions in the soil's mechanical performance Disfani et al. (2020).

The percentage of nickel slag used varies from 3%, 6%,

9% and 12%, which is based on the original soil weight ratio, this is based on

the opinion that the addition of additives above 15% is not cost efficient.

Before making the compacted test specimens, the soil and nickel slag that had

been pulverized were mixed and put into a plastic bag to cure for 24 hours for homogeneous water distribution Basha et al. (2004). After

that, the test specimens were made by mixing water into the mixed matrix by

adding water little by

little and stirring for 10 minutes until the mixture was homogeneous Carașca (2016).

At the final stage, the mixed matrix

was put in a mold and compaction was carried out based on

the standards used.

3. Results

3.1. Physical Characteristics of Nickel Slag Stabilized Clay Soil

The

results of testing the physical properties of clay soil before and after

stabilization efforts are shown in Table 1. Based on the sieve analysis,

it shows that the soil used is a clay material with a percentage of 72%. The

specific gravity (Gs) of the clay used has a value of

1.64, while the Gs of nickel slag is 2.87. From

mixing these two materials, the specific gravity for the 3%, 6%, 9% and 12%

variations were 1.23, 1.22, 1.21 and 1.20, respectively. These results

certainly explain that the addition of nickel slag to soil will reduce its specific

gravity and the amount depends on the percentage of nickel slag material added.

Table 1

|

Table 1 Physical Properties of Nickel Slag Stabilized Soil |

|||||

|

Physical Characteristics |

Value |

||||

|

|

0% |

3% |

6% |

9% |

12% |

|

Specific

gravity (Gs) |

1.87 |

2.12 |

2.34 |

2.36 |

2.38 |

|

Optimum

moisture content (wopt, %) |

36.08 |

|

|

|

|

|

Sieve

Analysis |

|

|

|

|

|

|

·

Sand (%) |

8 |

|

|

|

|

|

·

Silt (%) |

14 |

|

|

|

|

|

·

Clay (%) |

78 |

|

|

|

|

|

Atterberg

Limits |

|

|

|

|

|

|

·

Liquid Limit (LL) |

63.92 |

61.63 |

59.31 |

57.25 |

54.26 |

|

·

Plastic Limit (PL) |

42.16 |

44.95 |

47.29 |

48.13 |

48.13 |

|

·

Plasticity Index (PI) |

21.73 |

16.69 |

12.02 |

8.86 |

6.38 |

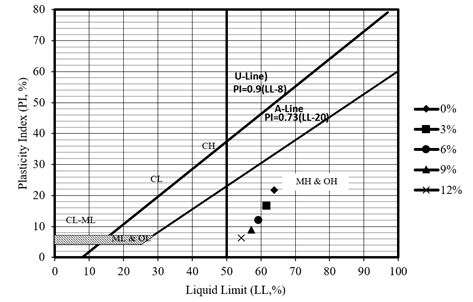

Figure 2

|

Figure 2 Classification of Clay Based on Casagrande Diagram |

CH

From

the values of the Atterberg limits, the clay soil used in this study can be

grouped based on the USCS (Unified Soil Classification System) classification.

This determination is based on the plasticity index (PI) and liquid limit (LL)

values plotted on the Casagrande soil classification diagram, where for a PI

value of 21.73 and an LL value of 63.92, the clay soil used is organic clay

soil with high plasticity, as shown in Figure 2. In addition, the results of

this test also show that the variation of nickel slag addition affects the

values of the Atterberg limits on clay soil. The addition of nickel slag at 3%,

6%, 9% and 12% affected the plasticity index values of the mixture matrix by

16.69; 12.02; 8.86; and 6.38, respectively. Thus, it can be stated that the

presence of nickel slag in clay soil will reduce its plasticity index.

3.2. Density Value of Nickel Slag Stabilized Soil

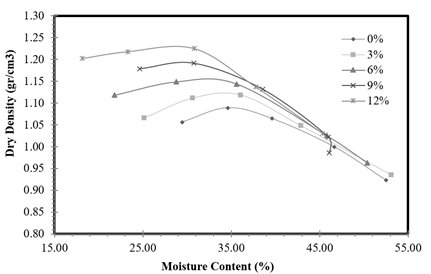

The

results of testing the density of clay materials without and with the addition

of nickel slag are shown in Figure 3. In general, it can be seen

that the presence of nickel slag as a stabilizing material in soft soil affects

the absorption of moisture content in clay soil, where the higher the

percentage of nickel slag, the higher the density value of the mixed material

obtained. In the nickel slag variation, the optimum dry soil density is in the

range of 30% - 36% moisture content.

Figure 3

|

Figure 3 Relationship Between Dry Density and Moisture Content |

The

relationship between the percentage of nickel slag content added to the clay

soil is shown in Figure 4. These results indicate that

the dry density characteristics (gdry) of the soil and nickel slag

mixture matrix continue to increase, where for nickel slag content of 3%, 6%,

9% and 12% resulted in dry density values (gdry) of 1.12 gr/cm3;

1.15 gr/cm3; 1.19 gr/cm3 and 1.23 gr/cm3 respectively.

These values illustrate that the presence of slag as a stabilizing agent in

organic clay soil with high plasticity, has not significantly increased the

density value of the mixed material.

Figure 4

|

Figure 4 Relationship Between Percentage of Nickel Slag and Dry Density |

4. Discussions

The overview of the results presented generally shows

that nickel slag has the potential to be developed as an alternative material

in soft soil stabilization efforts. In this study, the clay soil obtained from Subaim village has sand, silt and clay fractions of 8%, 14%

and 78%, respectively. Based on the PI and LL values, the soil is classified as

organic clay with high plasticity (OH). The technical characteristics of this

material are generally low bearing capacity,

easy deformation and high permeability Larsson (1996), where the amount of water absorption is

the main factor affecting its mechanical properties. The high-water absorption

in organic clay materials is due to the fibrous structure of the organic

material which contains more voids within its internal structure, thus having a

high-water absorption capacity Warrick (2002).

Stabilization efforts made through the use of nickel

slag waste in this study showed changes in the physical and mechanical

characteristics of the soil - slag matrix. The results obtained at the

Atterberg limits showed a decrease in the liquid limit (LL) between 3.46% -

11.64% and plasticity index (PI) between 14.83% - 82.61%, while the plastic

limit (PL) value increased between 3.45% - 7.96%. The effect of nickel slag on

the change of Atterberg limits is a physical compensation between the ratio of

plastic organic soil and non-plastic nickel slag material, which is similar to

sand or gravel. In addition, the addition of nickel slag to the clay soil used

can increase the dry density values varying between 2.66% - 12.47% depending on

the nickel slag content used, which of course is the result of changes in the

physical properties of the matrix of the soil mixture with nickel slag.

5. CONCLUSIONS

This study aims to determine the possibility of improving the geotechnical properties of organic soil by using by-products of the Nickel Processing Industry, in the form of crushed nickel slag. Based on the results obtained, there are several important points that can be concluded, namely: The liquid limit (LL) and plasticity index (PI) of organic soil decrease as the percentage of nickel slag used increases, which is shown in the change in soil classification. Changes in the physical properties of soil certainly affect its mechanical properties, where in this study an increase in nickel slag content can increase the maximum dry density of organic soil and cause the percentage of development to increase to a certain extent, then begin to decline.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Amhadi, T. S., & Assaf, G. J. (2019). Overview of Soil Stabilization Methods in Road Construction. GeoMEast 2018. Switzerland : Springer, 21-33. https://doi.org/10.1007/978-3-030-01911-2_3.

Basha, E. A., Hashim, R., & Muntohar, A. S. (2004). Stabilization of Clay and Residual Soils Using Cement - Rice Husk Ash Mixtures. Jurnal Teknik Sipil, 51-84.

Carașca, O. (2016). Soil Improvement by Mixing: Techniques and Performances. Energy Procedia, 85-92. https://doi.org/10.1016/j.egypro.2015.12.277.

Das, B. M. (2019). Advanced Soil Mechanics, (5th Ed.). London: CRC Press. https://doi.org/10.1201/9781351215183.

Disfani, M. M., Mohammadinia, A., Narsilio, G., & Aye, L. (2020). Performance Evaluation of Semi-Flexible Permeable Pavements Under Cyclic Loads. International Journal of Pavement Engineering, 336-346. https://doi.org/10.1080/10298436.2018.1475666.

Dodson, V. (1990). Pozzolans and the Pozzolanic Reaction. In: Concrete Admixtures. Springer, 120-159. https://doi.org/10.1007/978-1-4757-4843-7_7.

Firoozi, A. A., Olgun, C., Firoozi, A. A., & Baghini, M. S. (2017). Fundamentals of Soil Stabilization. International Journal of Geo-Engineering, 8(26), 1-16. https://doi.org/10.1186/s40703-017-0064-9.

Harianto, T., Marfu'ah, N., Rauf, I., & Leatemia, T. (2020). Experimental Study of Natural Materials Utilization as a Stabilization Agent on Soft Soil. IOP Conference Series: Materials Science and Engineering. https://doi.org/10.1088/1757-899X/875/1/012029.

Janz, M., & Johansson, S.-E. (2002). The Function of Different Binding Agents in Deep Stabilization. Swedish Deep Stabilization Research Centre.

Komang, A. U., Harianto, T., Muhiddin, B., & Arysad, A. (2022). Compressive Strength Characteristics of Trass Stabilized Dredged Soil. Journal of The Civil Engineering Forum, 301-308. https://doi.org/10.22146/jcef.3463.

Larsson, R. (1996). Chapter 1: Organic Soils. In Development in Geotechnical Engineering, 4-30. https://doi.org/10.1016/S0165-1250(96)80004-6.

Mariri, M., Moayed, R., & Kordnaeij, A. (2019). Stress-Strain Behavior of Loess Soil Stabilized with Cement, Zeolite, and Recycled Polyester Fiber. Journal Material of Civil Engineering. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002952.

Navagire, O. P., Sharma, S. K., & Rambabu, D. (2022). Stabilization of Black Cotton Soil with Coal Bottom Ash. Materialstoday, 979-985. https://doi.org/10.1016/j.matpr.2021.10.447.

Rauf, I., Gaus, A., Sultan, M. A., & Heryanto, H. (2023). Analysis and Characterization of Nickel Industry By-Products as Pozzolan Materials. Civil Engineering and Architecture. https://doi.org/10.13189/cea.2024.120130.

Rauf, I., Samang, L., Harianto, T., & Arsyad, A. (2020). Correlation of UCS and CBR on Lightweight Geocomposite of Soil-EPS Stabilized by Waste of Buton Asphalt. Material Science Forum, 998, 311-316. https://doi.org/10.4028/www.scientific.net/MSF.998.311.

Warrick, A. (2002). Soil Physics Companion. (Ed.). London, New York, Washington: CRC Press LLC. Boca Raton.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2024. All Rights Reserved.