REFINERY OF CITRONELLA OIL USING VACUUM HYDRODISTILATION METHOD IN ACEH UTARA DISTRICT

Syafruddin 1![]() , Reza Fauzan 1, Zulfan Khairil

Simbolon 2,

Rizal Syahyadi 3,

Atiqah Aida 1,

Rima Dhinta Dewi Astuti 1,

Pocut

Nurul Alam 4

, Reza Fauzan 1, Zulfan Khairil

Simbolon 2,

Rizal Syahyadi 3,

Atiqah Aida 1,

Rima Dhinta Dewi Astuti 1,

Pocut

Nurul Alam 4

1 Department of Chemical Engineering, Lhokseumawe State Polytechnic, Lhokseumawe,

North Aceh, Aceh 24301, Indonesia

2 Department of Informatics and Computer

Engineering, Lhokseumawe State Polytechnic, 24301 Lhokseumawe, North Aceh, Indonesia

3 Department of Civil Engineering, Lhokseumawe State Polytechnic, 24301 Lhokseumawe, North Aceh, Indonesia

4 Department of Chemical Engineering, Syiah Kuala University, Banda Aceh, Aceh, Indonesia

|

|

ABSTRACT |

||

|

Citronella oil

is a non-timber forest product (NTFP) and is commercially obtained from the

distillation of citronella leaves (Cymbopogon nardus

L). Fragrant citronella leaves are one of the raw materials for obtaining

vegetable oils in the form of essential oils. Essential oil is the main

component consisting of composition in the form of geraniol and citronellal.

The process of extracting essential oils can be done using various methods,

one of which is the Vacuum Hydrodistillation

method. The Vacuum Hydrodistillation method is

carried out using a vacuum pump as a pressure guard and the boiling point of

the distillation process does not exceed the boiling point temperature of

water, which is 1000 C, so that the oil produced is maintained its purity.

The vacuum hydrodistillation process of citronella

was carried out for 3, 5, and 7 hours with each treatment using random and

whole pieces of raw material. The resulting essential oil products were

analyzed in the form of yield, density, refractive index, and oil composition

analysis using GC-MS. The best essential oil yields from citronella were

obtained under operating conditions with random samples and distillation time

of 5 hours. Where the yield produced is 0.17% with a refractive index of

1.41570 and a density of 0.92735 gr/ml. |

|||

|

Received 28 October 2022 Accepted 29 November 2022 Published 10 December 2022 Corresponding Author Syafruddin, syafruddin.pnl@gmail.com

DOI10.29121/granthaalayah.v10.i11.2022.4905 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Essential Oil, Vacuum Hydrodistillation,

Fragrant Lemongrass, Geraniol |

|||

1. INTRODUCTION

Citronella oil is one of the most prospective oil commodities among the 12 essential oils exported by Indonesia. Market demand for essential oils is very large, especially for citronella oil, ranging from 9-10%. patchouli and vetiver oil which are in a lower position in terms of demand for citronella oil (veniter oil) BPS (2020). Hasanah et al. (2021), Mahjoub et al. (2013), Sulaswatty et al. (2019). Some areas that produce citronella oil include Nanggroe Aceh Darussalam, West Java, and Central Java with production of more than 95% of total production in Indonesia Directorate General of Plantations, (2013). Mahjoub et al. (2013) With a fairly large number of sales of essential oils, the selling price of these oils is still affordable and very cheap. This is because the quality of the quality requirements does not meet the qualifications. Limited public knowledge regarding the processing of refining citronella oil is the main key cause for the decline in the quality of citronella oil. Zaituni et al. (2016), Hidayati et al. (2015) According to a report from the Ministry of Trade (2011) world citronella oil production is approaching 4000 tons and 40% of its sources are supplied by China and Indonesia. The low production of citronella oil can further increase the value of citronella oil with the presence of derivative products from this oil. Various uses of fragrant citronella oil that can be used such as making cosmetic products, food, beverages. The fragrance can last below the boiling point of water, so it doesn't damage the content of the citronella oil itself. Bojan et al. (2007), Daryono et al. (2014), Eka Jati et al. (2010).

2.

METHODOLOGY

The raw material used is fragrant citronella. While the equipment used is a set of vacuum hydrodistillation tools, refractometers, pycnometers, measuring pipettes, Erlenmeyer, and a set of 50 ml titration tools. 25 liters of water is put into the distilled kettle. Esmaeili et al. (2018), Gavahian et al. (2018), Ghifary (2008) 10 kg of prepared citronella leaves with whole size and random pieces are put into the distilled kettle. The pump is turned on to circulate the cooling water, then the heater is turned on until it reaches a temperature of 100oC and then the distillation process is carried out by varying the boiling time. Variation of boiling time is 3.5 and 7 hours. Gill et al. (2017), Ibrahim (2021) During the boiling process, the steam from citronella leaves will be cooled using cooling water. So, the oil will come out through the condenser. After the distillation process is complete, the yield of the oil obtained is calculated and the quality of the essential oil is analyzed. Jayanudin and Hartono (2011).

2.1. GAS CHROMATOGRAPHY-MASS SPECTROMETRY (GC-MS) ANALYSIS

Analysis of citronella oil samples was carried out using GC-MS gas chromatography (GC-Shimadzu 2010 with an autosampler and ionization detector. GC-MS was connected to a mass spectrometer (Agilent 5975C) using a DB-1MS capillary column (30 x 0.25 mm 1. D) 0.25 πm layer thickness). Injector and detector temperatures were set at 250 oC. Oven temperature was programmed at 40 oC for 8 minutes, increased at 3 oC/min to 240 oC and then held for 10 minutes. Helium as carrier gas was set to flow rate of 1.2 mL/min.The sample volume injected was 10 MI with the aim of qualitatively identifying the presence of compounds present in citronella oil. Kültürela and Tarhan (2016), Kumar et al. (2016).

2.2. OIL YIELD ANALYSIS

Calculate the weight of the citronella to be refined (input), then calculate the final weight of the fragrant citronella oil obtained (output). Kumar et al. (2016).

Yield (%) = Weight

of refined oil (output) x 100%

Weight of distilled citronella (input)

2.3. DENSITY ANALYSIS

1. Weigh the empty

chemical pycnometer

2. Fill the empty

pycnometer with essential oil distillate

3. Reduce the mass

of the pycnometer which has been filled with yield with a beaker empty

4. Then the mass and volume are obtained

𝜌 = m/v

2.4. BIAS INDEX ANALYSIS

1) Drop the sample to be checked for its

refractive index in the sample container Refractometer.

2) Cover tightly and allow light to pass through

the solution and through the prism. So that the light on the screen in the tool

is divided into two.

3) Slide the boundary mark by rotating the

adjusting knob, until intersects the point of intersection of two diagonal

lines that intersect with each other on screen.

4) Observe and read the refractive index scale

indicated by the screen needle through a microscope.

5)

Two-color result display that has been set up so as to provide

two colors that have a clear and firm color.

3. RESULTS AND DISCUSSIONS

From the results

of research on distillation of essential oils from citronella using the vacuum hydrodistillation method as follows: Table 1

Table 1

|

Table 1 Results of Research |

||||||

|

Sample Size |

Distillation Time (Hours) |

Color |

Refractive Index (π) |

Acid Number |

Density (gr/ml) |

Yield (%) |

|

Random Pieces |

5 |

Clear |

1.41570 |

4.32 |

0.92735 |

0.17 |

|

6 |

Clear |

1.41508 |

4.49 |

0.85838 |

0.29 |

|

|

7 |

Clear |

1.41493 |

4.66 |

0.86406 |

0.37 |

|

|

Intact |

5 |

Clear |

1.41547 |

4.32 |

0.83954 |

0.13 |

|

6 |

Clear |

1.41484 |

4.88 |

0.83000 |

0.22 |

|

|

|

7 |

Clear |

1.41464 |

4.49 |

0.82947 |

0.27 |

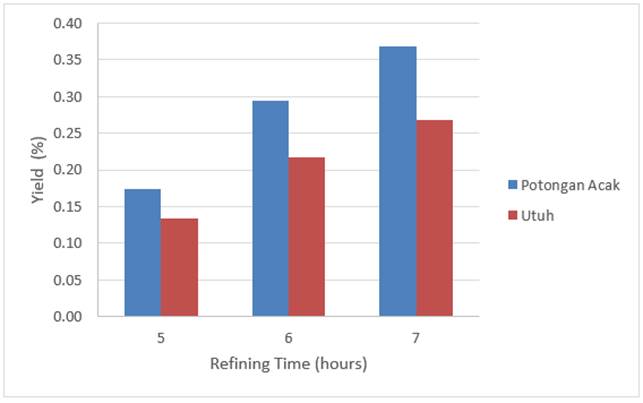

3.1. YIELD

Below is a graph showing the yield levels for samples of the full size

and random pieces.

Figure 1

|

Figure 1 Effect of Distillation Time on Essential Oil Yield Levels |

From the research

that has been done, it is known that the highest oil yield was obtained from

the vacuum hydrodistillation process with random

sample pieces and 5 hours of distillation time, which is equal to 0.17%. This

is because the samples that were randomly cut have a smaller size than the

whole pieces the more surface area, so the oil will be easier to extract.

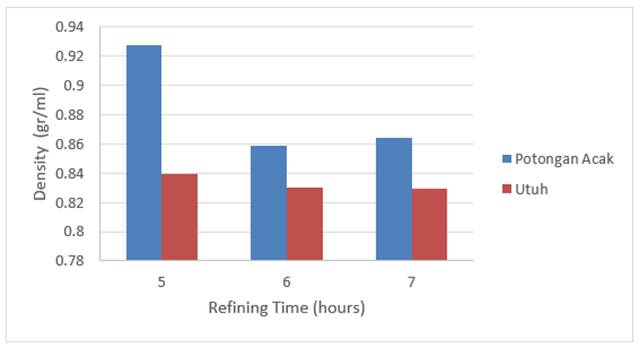

3.2. DENSITY

Figure 2

|

Figure 2 The Effect of Distillation Time on the Density of Essential Oils |

From the graph

above it can be seen that the distillation time affects the density of the

essential oil obtained, where the longer the distillation time the lower the

density of the oil. And for the best density value, it was found in samples

with random pieces and 5 hours of distillation time, which was 0.92735 gram/ml.

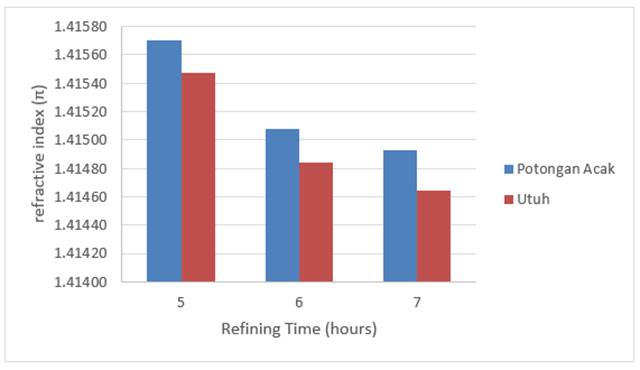

Figure 3.

Figure 3

|

Figure 3 The Effect of Distillation Time on the Refractive Index of Essential Oils |

From the graph of the relationship between distillation time and the

value of the refractive index of the essential oil samples, it can be seen that

the distillation time has an effect on the refractive index. Where the longer

the refining time, the lower the refractive index. This is because the longer

the oil is extracted at a certain temperature, the components of the essential

oil will be damaged, so that the value of the refractive index decreases. While

the comparison between the size of the intact sample and the random section, it

was found that the index of refraction in the random section was higher than

that of the intact sample. According to Ibrahim (2021) the higher the refractive index obtained, the

better the quality of the essential oil obtained. Obtained essential oil with

the best index of refraction that is in the sample with a random sample size

and distillation time of 5 hours.

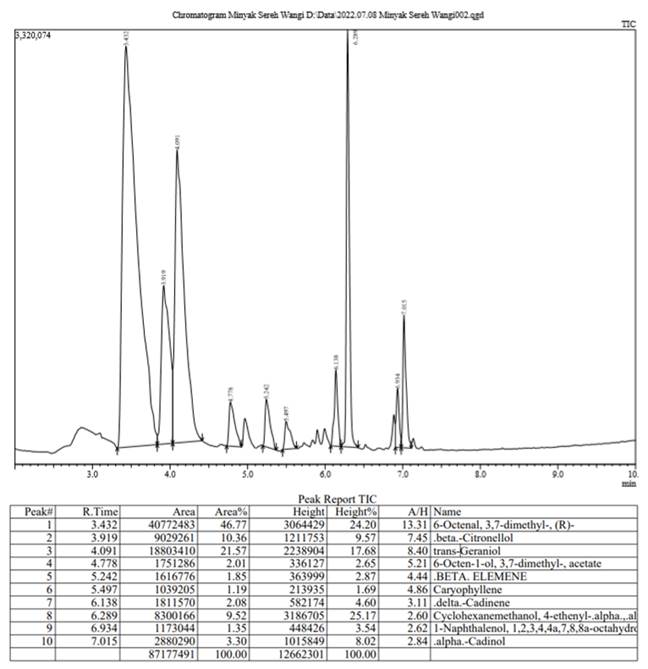

3.3. COMPOSITION ANALYSIS OF

FRAGRANT CITRONELLA OIL WITH GC-MS TOOL

Figure

4

|

Figure 4 Results of GC-MS Analysis of Fragrant Citronella Oil |

From

the results of the GC-MS analysis it can be seen that the chemical compounds

identified were 21.57% Geraniol and 10.36% Citronellol. Geraniol levels in

essential oils are usually used for making perfume.

4. CONCLUSION

In this study it can be concluded that the distillation of citronella oil by vacuum hydrodistillation method is very effective. Seen from the results of the analysis of essential oils obtained. For the best distillation time for 5 hours of distillation with random pieces.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

The author would like to thank the Ministry of Education and Culture of the Republic of Indonesia for their support.

REFERENCES

Adiwijaya, J. C., and Malika, U. E. (2016). Feasibility of Essential Oil Refining Business Based on Financial and Technological Aspects. Scientific Journal of Innovation, 16(3).

Anshori, J. A., and Hidayat, A. T. (2009). Basic Concepts of Distillation and Simple Analysis of Patchouli Oil. Institute for Research and Community Service, University of Padjadjaran.

Bojan,

M., Apostol, D., Damian, V., Logofatu, P., Garoi, F., and Lordache, L. (2007).

Refractive Index Measurement Using Comparative. SPIE Proceedings, 6635. https://doi.org/10.1117/12.741908.

Daryono, E. D., Pursitta, A. t., and Isnaini, A. (2014). Extraction of Essential Oils from Basil Plants with N-Hexane Solvent. Journal of Chemical Engineering, 9(1), 1-7.

Eka Jati, BM, Karyono, and Supriyatin. (2010). Equalization of Viscosity Value of Refractive Index in Clear Liquids. Periodic Physics, 13 (4),119 - 124.

Esmaeili, H., Karami, A., and Maggi, F. (2018). Essential Oil Composition, Total Phenolic and Flavonoids Contents, and Antioxidant Activity of Oliveria Decumbens Vent, (Apiaceae) at Different Phenological Stages. Cleaner Production, 198, 91-95. https://doi.org/10.1016/j.jclepro.2018.07.029.

Ferdayanti, M. et al. (2014). Concentration of Citronellal in Citronella Oil (Cymbopogon Nardus L.) by Distillation Fractionation and Identification Using Kg-Sm. Indonesian Journal of Chemical Research, 2 (1), 28-34. https://doi.org/10.20885/chemical.vol2.iss1.art4.

Gavahian, M., Lee, Y., and Chu, Y. (2018).

Hydrodistillation of Citronella Oil from Taiwanese Citronella Grass : Impact on

the Essential Oil and Extraction Medium. Innovatice Food Science and Emerging

Technologies, 466 - 8564.

https://doi.org/10.1016/j.ifset.2018.05.015.

Ghifary, H. (2008). Analysis of the Distillation Process of Essential Oil from Lemongrass (Citronella) Leaves Using the Direct Steam Method. Brawijaya Knowledge Garden.

Gill, D., Roca, L., Zaragoza, G., and Berenguel, M. (2017). A

Feedback Control System with Reference Governor for a Solar Membrane

Distillation Pilot Facility. Renewable Energy, 120, 536-549. https://doi.org/10.1016/j.renene.2017.12.107.

Gultom, E. S. et al. (2020). Utilization of Citronella Plants (Cymbopogonnardusl) as Air Freshener Herbal Mosquito Repellent in Bandar Khalifah Village, Percut Sei Tuan District, Deli Serdang Regency. National Seminar on Community Service Results LPPM UNIMED, Medan, 183-186.

Hasanah, U. et al. (2021). Isolation of the Anti-Bacterial Compound Geraniol from Citronella Oil Using Vacuum Distillation. Technology Journal,21(1), 32-38.

Hidayati, N., Ilmawati, H., and Sara, E. (2015). Nutmeg Seed Oil Refining: Effect of Material Size, Time and Refining Pressure on Oil Quality and Yield.

Ibrahim, B. (2021). Distillation of Essential Oils from Lemongrass Using the Steam Distillation Method. Lhokseumawe State Polytechnic Chemical Engineering, 1-40.

Jayanudin, J., and Hartono, R. (2011). Essential Oil Distillation Process with Steam Method Made from Patchouli Leaves. Journal of Science and Technology Untirta, 7 (1).

Kumar, R., Nawroth, P. P., and Tyedmers, J. (2016). Prion Aggregates Are Recruited to the Insoluble Protein Deposit (IPOD) via Myosin 2-Based Vesicular Transport. Pls Genetics. https://doi.org/10.1371/journal.pgen.1006324.

Kültürela, Y., and Tarhan, S. (2016). A Sollar Distillery of Essentials Oil with Compound Parabolic Collectors (Cpcs). Agricultural Sciences 31, 71-83. https://doi.org/10.7161/ANAJAS.2016.31.1.72-83.

Mahjoub, R., Mohamad Yatim, J. B., and Mohd Sam, A. R. (2013). A Review of Structural Performance of Oil Palm Empty Fruit Bunch Fiber in Polymer Composites. Advances in Materials Science and Engineering, 1-9. https://doi.org/10.1155/2013/415359.

Shintawati, S., Rina, O., and Ermaya, D. (2020). Antimicrobial Properties and Effects of Raw Material Treatments on Citronella Oil Yield. Sylva Lestari Journal, 8(3), 411-419. https://doi.org/10.23960/jsl38411-419.

Sulaswatty, A. et al. (2019). Quo Vadis Citronella Oil and its Derivative Products. Jakarta : LIPI.

Sumarni, S., Aji, N. B., and Solekan, S. (2008). Effect of Water Volume and Material Weight on Essential Oil Distillation. Journal of Technology, 1(1), 83-87.

Zaituni, Z., Khathir, R., and Agustina, R. (2016). Distillation of Citronella Essential Oil (Cymbopogon Citratus) Using the Water-Steam Distillation Method. Agricultural Student Scientific Journal, 1(1), 1009-1016. https://doi.org/10.17969/jimfp.v1i1.1085.

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© Granthaalayah 2014-2022. All Rights Reserved.