|

|

Article Type: Research Article

Article Citation: Dr. Anjali Pandey. (2020). LACQURED

CRAFT OF SHEOPUR- A SUSTAINABLE CRAFT OF MADHYA PRADESH. ShodhKosh: Journal of Visual and Performing Arts,

1(2), 1-11.

https://doi.org/10.29121/shodhkosh.v1.i2.2020.5

Received Date: 19 May 2020

Accepted Date: 15 December 2020

Keywords:

Woodcraft

Lathe-Turned

Lacquered Craft

Lac

Craft

Craftsmen

Eco-Friendly

ABSTRACT

The world of arts and handicrafts represents a great saga of

culture, traditions and historical legacy associated with each particular

region. India, in general and Madhya Pradesh, in particular are known for the

impressive range of hand-made artifacts that enthrall onlookers, buyers and

collectors of art.

The innate are honored with the characteristic specialty of

cutting and make extremely appealing things. There are wooden chowkies made for estimating grains. Wedding mainstays of Bharia and wooden entryways of Gonds

and Korkus are extremely appealing and unordinary.

Machines turned and lacquered toys in splendid hues and at moderate costs are

famous everywhere throughout the state. Cut wooden toys, dolls and elephants

displaying the abilities of the craftsman are likewise made.

The Woodcrafts of Madhya Pradesh are self-viable and have

contributed in maintaining the environment healthy by using all the natural

colors and polishes. Moreover, it generates the employments to the artisans,

which encourages them to design and produce the products as per the market

demands. And as per the demand it

encourages the Social-distance which is much need in present scenario.

1. INTRODUCTION OF MADHYA PRADESH

Taking an excursion along the core of India we go over

entirely saved medieval urban communities, invigorating and captivating natural

life havens, and probably the holiest and most venerated traveler habitats that

pull in the pioneer profound into its reality. Madhya Pradesh is the core of India, and geologically involves

conclusive spot in the nation's gather in territories which are creating

different items like handloom fabric, silk and fleece. Wood work and finish

product of Madhya Pradesh are likewise extremely acclaimed. Coal and iron are

generally significant of the minerals found in Madhya Pradesh. For the creation

of concrete, limestone is required which can be found in excessive sum in

Madhya Pradesh. In a few regions of the state, Marble is likewise accessible.

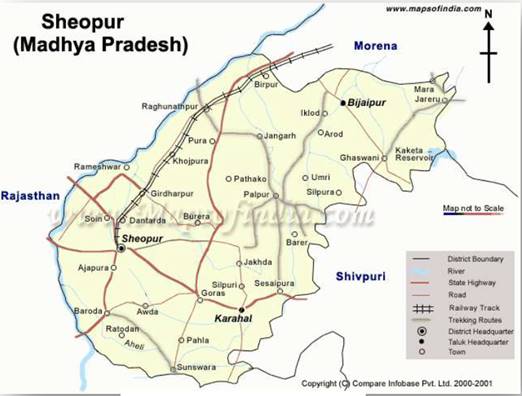

Figure 1: Google image

1.1. ART AND CULTURE

Madhya

Pradesh is the home ground for most of innate populace of India which by and

large, live away from the standard India. Traditional village crafts such as Chanderi sarees, leather, clay toys make it famous. It is

especially known for its lacquer-ware products. Being centrally located amidst

a vast span of forest covered land some of the areas like Sheopur,

Rewa and Gwalior have exposure to a wide range of the

available wood, which nurtures the art of lacquer-ware in these areas. In spite

of the infringing impact of twentieth century urban life, the clans have to a

great extent figured out how to hold their own specific manner of life,

generally immaculate by modernization. [2]

2. ABOUT THE CLUSTER

2.1. HISTORY

Sheopur

town likewise called Sheopur kalan,

is situated in the north western part of Madhya Pradesh state in central India.

The town and stronghold were established in 1537 by gaur Rajputs

and filled in as capital of the previous Sheopur

regal state. A street intersection and rail end, it is a significant market

known for its lacquered woodwork and playing a game of cards. [3]

2.2. GEOGRAPHICAL LOCATION

Sheopur

is situated at the north western part of Madhya Pradesh. The region is all

around associated by Road and Railway Network. It is associated by normal

transport service with Gwalior, Morena, and Kota. Sheopur

is 210 km away from Gwalior and 230 km away from Morena. The significant

streams like Chambal, Seep and Kuno are famous in the

area. [4]

Figure 2: Google image

2.3. ARTS AND CRAFTS

The

specialty of woodcarving has prospered in the area of Sheopur

and the wonderfully decorated wooden roofs, entryways and lintels with finely

cut plans are quiet tributes of its greatness. The wood carvers of Sheopur, with extraordinary affectability and aptitude

change various assortments of wood. The specialty people of Sheopur

make pipes, covers, toys, entryways, stands, windows, wooden remembrances,

blossom jars, bedposts and support posts etc. [5]

2.4. ABOUT THE CRAFT

Lacquer-craft

is the utilization of enamel on wood in satisfying shades to make a particular

allure. This art creates an enormous assortment of beautifying just as utility

things. Lacquering is done on a machine, hand or machine worked. For turning

thin and fragile things, the hand-machine is liked. Lac is applied in a dry

state. The lac stick is squeezed against the woodenware to be lacquered. As the

last continues spinning the warmth from erosion mollifies the lac, empowering

the shading to stick. Plans are painted with a brush on figures, protests and

toys.

Figure 3: Picture by Mitali Pandey Minare

For its application lac is warmed to get a semi fluid state

then it is worked and colors are added, at that point attracted to be made into

sticks and afterward covered over the wooden articles. It is a reasonable or

shaded covering that dries by dissolvable dissipation and frequently a

restoring cycle too that creates a hard, tough completion in any sheen level

from super matte to shiny and that can be additionally cleaned as required. [5]

![]() The specialty

delivers a huge assortment of improving just as utility things including little

models of kitchenware, toys, seats, table lights, etc. Mathematical and

botanical examples are usually utilized in the plans. These plans are painted

in a few blends as indicated by the craftsman extravagant. Among the most well

known veneer product are the lac bangles. Heretofore studded with gold and

valuable stones, today they are likewise accessible with dots, glass, stones,

mirrors and that's just the beginning.

The specialty

delivers a huge assortment of improving just as utility things including little

models of kitchenware, toys, seats, table lights, etc. Mathematical and

botanical examples are usually utilized in the plans. These plans are painted

in a few blends as indicated by the craftsman extravagant. Among the most well

known veneer product are the lac bangles. Heretofore studded with gold and

valuable stones, today they are likewise accessible with dots, glass, stones,

mirrors and that's just the beginning.

Colored

lacquer ware is made in Sheopur, Rewa Budhi, Bhopal, Gwalior, Ratlam and Sabalgarh

in Madhya Pradesh. Etikoppaka in Andhra Pradesh

is one of the most important centers of this craft. The lacquerware of Savantvadi, once a princely state, is a traditional craft.

Chennapatna6 in Karnataka state holds an honored place in the

lacquer ware world.

2.5. DIVISION OF LACQUER WARE INDUSTRY

The

lacquer industry can be divided into:

1) Independent workshop units,

2) Small scale enterprises and

3) Medium scale industries.

1) Number of family members which

incorporates men, ladies and kids may create polish product. They have around

2-3 machine worked either by hand or lathe machine in their homes or little

workshops developed close by. The vast majorities of them is independently

employed and are showcasing their items to neighborhood market or obliging

greater brokers.

2) Limited scope undertakings are

set-up in specialists’ houses with a base 5 machines. The recruited specialists

deal with per piece rate premise. These limited scale undertakings sell their

items straightforwardly to exporters. These limited scale ventures don't have

an enormous edge of benefit as the specialists are generally government driven

organizations which utilize weighty charges and manipulative commissions.

3) Medium scale ventures are set up

or possessed by exporters as it were. Significant urban communities like

Bangalore possessing colossal edges of benefits as the transportation and work

charges are exceptionally less. There are a couple of exporters in Bangalore

who have contracts with craftsmans for the ideal

amount of creation of the given things. Exporters give particulars depicting

the ideal items with a severe spotlight on quality. These ventures are

available to new and innovative thoughts of plan and imaginativeness as they

take into account a lot higher objective market. [7]

2.6. ECONOMIC STATUS OF CRAFTSMEN

The

craftsmen are solely dependent on this art for their livelihood. The women in

the house work as bidi makers to support the house financially. When these

craftsmen source their products to the neighboring villages they get a much

higher amount of work than the amount they get after selling the products in

main cities as there is no taxation taking place during the transport and

handling of the products. Due to their one track traditional designs they have

been following since a long time their products have not yet reached the

corporate market or the main arena of creative lacquer design. Fare items

should meet and satisfy to new requests and particulars. These new items need

to keep up all the more demanding principles of value and may require more mind

boggling and complex work of art or completing than different items which are

sold in nearby business sectors. There were 15 families following the tradition

of making lacquer-ware products. These families have been inheriting this art

as their hereditary trait and all the boys in the families are presumed to do

the same. [8]

3. MATERIAL AND TOOLS USED

3.1. LAC

Lac is the resinous discharge delivered by the insect Technadria

lacca. It is found on a huge numbers of the woods

trees, especially in kusum (Schleichera

oleosa). At present, it is gathered in different

states like Bihar, Orissa, Uttar Pradesh and West Bengal, Madhya Pradesh,

Maharashtra

There are three distinct assortments of lac that are being utilized in

the enamel product measure. The exceptional quality lac is referred to as catch

lac for what it's worth in the catch structure. It is light and brilliant in

hued and can cost up to Rs. 450/kg. The second is in medium earthy colored tone

and accessible in Rs. 300/kg. The third and the least fortunate quality lac is

in dull dark tone and is Rs 250/kg.

Lac

sticks are manufactured on a domestic basis by the women folk or the craftsmen

themselves in the village. They buy the raw lac that is in the form of crystals

according to the requirement of the work. The crystal material is usually light

brown in color. Water is boiled at a very high temperature in a pot and the

crystals are then put into it for melting. The crystals melt into a sticky

elastic substance which is then handled with the help of long wooden sticks.

When the lac becomes soft, it is taken on the ground and with the help of

wooden sticks is stretched and batted on the floor till it turns into a thick

lac stick. This takes a time span of 15-20 minutes.

|

|

|

Figure

4: Picture by Mitali Pandey Minare

3.2. COLOR PIGMENTS

The lac

with no extra color pigment gives natural color to the wood. For obtaining

different colors, oxides of iron, zinc and magnesium are added during the

process of batting the lac on the floor. Colors like turquoise, red, green,

black, white and purple are obtained.

Figure 5: Picture by Mitali

Pandey Minare

3.3. MEDIUM OF APPLICATION

Talegiri

(Pandanus odoratissimus) is otherwise called screw

pine and privately known as "keware ka patta" among the neighborhood specialists. This

evergreen tree has palm-like leaves which can either have lots of long thick

leaves or have an unmistakable bole up to 6 meters in stature. The screw pine

frequently has flying roots and are horse regularly found on the coast and

along banks of waterways, trenches, fields and lakes,. The leafs

are the significant embellishment in enamel product creation and are chiefly utilized

for cleaning and give reflexive completion to the item. A heap of 100 leaves

costs around Rs. 20. [9]

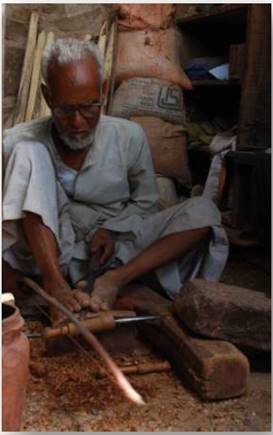

3.4. HAND LATHE MACHINE

Many of

the craftsmen still engage in traditional methods, evolving suitable kinds of

hand lathes called patris in their

local language. This consists of a heavy block of wood and stone which act as

the object holder and the rotating shaft which is made by a bow string. This

prevails as a popular method as the older craftsmen find it more convenient,

easier and faster to work on hand lathes rather than the fast moving modern

lathe machines, as hand lathe gives them the freedom of speed of the work

according to the art on the object and they can adjust it easily according to

their sitting positions.

Figure 6: Picture by Mitali

Pandey Minare

The hand

lathe arrangement is very precisely calculated and then developed, the distance

of the stone holding the object is manually adjusted according to the size of

the foot from one of the corners of the supporting wood. The angles are kept

such that the object does not fly off while the rotation process, this analysis

helps them work more efficiently and creatively. [10]

3.5. ELECTRIC POWER LATHE MACHINE

With the

expanding market for polish product the electric force machine has been

presented. A force machine has a head stock that comprises of a rotating pivot

connected to two belt pulleys. The belt runs over a pulley mounted on a

spinning shaft that is driven by an electric engine.

Figure 7: Picture by Mitali

Pandey Minare

The creation time impressively lessens on the power lathe

machine, as both the hands are allowed to work turning devices. Force machines

are for the most part situated in little processing plant settings, where there

is no or less issue of power. Also, the modern lathe machine helps the young craftsmen of the

community to mass produce the products at a much faster speed. The craftsmen in

Sheopur had been trained by a professional craftsman

in Bangalore about the proper use of the machines. The young members of the

community use the lathe machines to produce more commercially viable and

intricate designs which helps them take their craft one step further from the

traditional designs and techniques. [11]

4. WORKING PROCESS

4.1. WORKING STYLE

The work

is carried out in a workshop and in places where the artisans have turned one

part of their house into a workshop. Their workshops are so small that it can

only adjust at the most 2-3 people inside apart from the person working on his

machine. Working space per worker is 2 X 3 ft. The same condition is in the

entire workshop. The space is very less yet it has every possible thing

required by them in that area.

Figure 8: Picture by Mitali

Pandey Minare

Every

worker has his own set of tools which is spread on the ground at an arms

distance. The lighting condition is bad as they have only one source of light

that is placed wrongly in many cases. So, when the natural light is not strong

it become darker and hence difficult to work with perfection. This happens

mostly between evening hours.

Those

workshops which are situated in the market get affected by the other activities

in the surrounding. The work also gets hampered in the works hops which have a

retail counter in front of the workshop. This is due to the fact that craftsmen

would be required to attend to the customers.

They do

not have any recreational or entertaining activities taking place around them

as the only source of entertainment is to keep talking to the person beside you

or the women of the family who keep sitting beside and making bidis. [12]

4.2. PRODUCTION PROCESS

The

production of lacquered items consists of a series of processes. This work is

accomplished on a hand or mechanized lathe machine placed within the house and is

turned into a workshop. The arrangement of log wood for lac-turnery starts with

preparing.

Figure 9: Picture by Mitali

Pandey Minare

1) Logs are cut into

little pieces (billets) and put away in a airy spot away from warmth and

daylight for around ten days to a month, contingent on the dampness substance

of the wood.

2) ![]() The edges of the

prepared billets are then etched until a chamber is framed. Presently the wood

is fit to be turned on a machine.

The edges of the

prepared billets are then etched until a chamber is framed. Presently the wood

is fit to be turned on a machine.

3) Cutting instruments are utilized

to the rotating wood-piece with the goal that undesirable flimsy ceaseless

chips are scratched off. Gifted specialists can eliminate uniform and dainty

layers of wood to frame it into wanted shapes.

4) Once the ideal shape is

accomplished, it is sanded with sandpaper on pivoting machine, until the

surface is smooth and uniform.

|

|

|

Figure 10: Picture by Mitali Pandey Minare

5) At this stage the article is fit

to be lacquered. The nature of the eventual outcome relies upon the ability

with which finish is applied to the turning wood. A lac stick of the picked

shading is squeezed to the spinning wood. The contact makes the lac dissolve

and spread consistently over the region on which it is applied.

6) Final completing is finished

utilizing a screw pine leaf to help spread the lac on the turning wood and

finish the article. Polishing by kewra leaf loans a clarity to the completed

item.

7) The lacquered article is isolated

with a cutting instrument and eliminated from the machine. Now, a few articles

are additionally ornamented with paint. [13]

|

|

|

Figure 11: Picture by Mitali Pandey Minare

5. PRODUCTION OF LACQUER

1) The process of preparation of enamel from lac starts with warming and mellowing.

2) Lac is adhered on to the finishes of two wooden sticks which are warmed until the lac gets plastic and pliant.

3) The warming cycle is sometimes rehashed to look after versatility. A particular measure of lithophene is then added to the mellowed lac and is constantly beaten until a white color shows up.

4) A little part of powdered color is blended in with a little bit of water and this is added to the warm white lac.

5) The blend is then beaten until the right shade develops. The lac at that point starts to expect the consistency of elastic.

6) The lac is warmed, and is taken out from the splinters before it sets. A long flimsy stick of colored lacquer of 1 cm thick and 3 cm wide is molded and afterward cut into 15-20 cm lengths.

7) Around Four to five sticks of one tone can be set up at an equivalent time. These sticks have a time span of usability of just a single month before they become hard and unsuited for lacquering. [14]

|

|

|

|

|

|

|

|

|

|

|

|

Figure 12: Picture by Mitali Pandey Minare

![]()

6. ABOUT THE MASTER CRAFTSMEN

The

design development program was conducted in the direction of Mr. Sarkar Ahmed.

He was the master craftsmen of this program. He is 65 yrs. old and is associated

with this traditional craft sector since 45 yrs. He is continuing the heritage

art of his forefather which is 500 yrs. old. He also encourages his sons to

take forward this craft.

He has

registered himself with MPHSVN, DCH and many other Govt. organizations and

attended many workshops and training program organized by them. He also has

showcased his craft in many exhibitions held at Bhopal, Jaipur and Delhi.He himself had made various products according to the

market demand and change but his best works out of this craft is Corner table,

dolls, saras lamp, wall plate (painting), and

cannons.

The

products which are now seen in the market were very different as compared to

the previous ones. Mr. Sarkar Ahmed adds to this that earlier they made products

which were widely used like toys or kitchen items or decorative stuff. Which

includes Itradaan, kamal ka phool, shatranj, chaupad, shahnai, surme-dani, fan, In toys- aeroplane,

chidiya gadi, jhunjhuna,

tricycle, bat-ball, In decoration stuff they made- lantern, flowerpot, doll lamp, keyring, peacock. dancing dolls,

bangle stand etc. At this age also he is very proactive and attends

workshops being organized and participates in exhibitions.

7. CONCLUSION

Sheopur

has a vast potential in lathe-turned wood craft. Since ages this craft is

flourishing in this area and has gradually astonished the potential buyers of

handicrafts. Craftsmen have evolved this craft from the basic household items

like chair, table and toys for kids to the home-décor and souvenir products. On

my field work, I figured out the challenges and the strength of the craft. The

kind of patience it demands and the way it portray its uniqueness in terms of

self-sustainability. Many Govt. organizations are coming forward to promote and

uplifting this craft as it is eco-friendly and has no hazardous impact on the environment;

furthermore, it provides employment for the craftsmen and Wood-turned craft is

therefore are attracting not only the Indian craft lovers but also the foreign

buyers from different countries. Moreover, in today’s context it promotes the

new campaign started by the Govt. called “VOCAL

FOR LOCAL”

SOURCES OF FUNDING

None.

CONFLICT OF INTEREST

None.

REFERENCES

[1] https://en.wikipedia.org/wiki/Madhya_Pradesh

[3] https://sheopur.nic.in/en/history/

[4] http://www.mponline.gov.in/Portal/Content/districts/Sheopur.html

[5] http://handicrafts.nic.in/CmsUpload/2039201602393132%20craft%20process.pdf

[6] http://www.craftandartisans.com/wooden-lacquerware-of-chennapatna-karnataka.html

[7] http://www.fao.org/3/X5859E/x5859e04.htm

[8] Interview with the master craftsmen. Shri. Sarkar Ahmed

[11] https://en.wikipedia.org/wiki/Lathe#Woodworking_lathes

[12] Interview with the artisans Shri Zakir Hussain

[13] Interview with the artisans Shri Sartaj Ahmed (Son of Sarkar Ahmed)

[15] Picture 1-2 from google source

[16] Picture 3-12 taken by me

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2020. All Rights Reserved.