|

|

|

|

Artificial Intelligence in Supply Chain: Revolutionizing Forecasting and Decision-Making

Dr. Prakash Divakaran 1![]() , Dr. Vandana Mishra Chaturvedi 2

, Dr. Vandana Mishra Chaturvedi 2![]()

1 Pro-Vice

Chancelor & Professor, Department of Business Administration, Himalayan

University, Itanagar, Arunachal Pradesh, India

2 Vice-Chancellor,

D Y Patil Deemed to be University, Sector -7, Vidya Nagar, Nerul, Navi

Mumbai-400706, India

|

|

ABSTRACT |

||

|

Within the

realm of supply chain management, Artificial Intelligence (AI) has emerged as

a game-changing technology that has the potential to revolutionize

forecasting as well as the decision-making process. This study investigates

the use of artificial intelligence (AI) in the operations of supply chains,

as well as its influence on the accuracy of demand forecasting, planning,

inventory management, and decision-making. This article goes into the

numerous artificial intelligence approaches, such as machine learning,

natural language processing, and predictive analytics, that are used to

analyze massive volumes of data and provide meaningful insights. The study

also examines the advantages and problems connected with integrating AI in

supply chains. These include the quality of the data, the needs for the

infrastructure, and the preparedness of the organizations. In addition to

this, it provides real-world examples and case studies that illustrate the

effective uses of AI in supply chain management. The results highlight the

potential for AI to increase customer service, improve supply chain

efficiency, optimize inventory levels, and allow proactive decision-making.

It is anticipated that as AI continues to make advances, it will transform

supply chain procedures and provide firms with the ability to react to an

increasingly complex and volatile economic environment. |

|||

|

Received 15 December 2023 Accepted 16 January 2024 Published 31 January 2024 Corresponding Author Dr.

Prakash Divakaran, prakash@himalayanuniversity.com DOI 10.29121/ijetmr.v11.i1.2024.1641 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: AI and Supply

Chain Planning, Technological, Digital Security and Privacy, Digital

Environment, Technology Privacy |

|||

1. INTRODUCTION

In recent years, the discipline of supply chain management has been subjected to major changes. These shifts have been brought about by developments in technology as well as an increased emphasis on optimizing business operations. The advent of Artificial Intelligence (AI) as a potent instrument that is transforming different parts of supply chain operations, notably in the processes of forecasting and decision-making, has occurred relatively recently. AI makes use of sophisticated algorithms and data analysis methods to mine massive amounts of data for useful insights, so empowering enterprises to make choices that are both educated and proactive in nature.

Forecasting and decision-making in supply chains have traditionally depended significantly on human analysis and historical data, which often resulted in mistakes and inefficiencies. More recently, however, automated analysis has begun to replace these methods. However, with the incorporation of AI technologies, businesses are now able to leverage the power of machine learning, natural language processing, and predictive analytics to increase the accuracy of their forecasts, boost demand planning, optimize inventory management, and provide assistance for strategic decision-making. Butcher and Grant (2012)

The purpose of this study is to investigate the use of artificial intelligence (AI) in supply chains and its potentially game-changing effect on forecasting and decision-making procedures. It will look into the many AI approaches that are used, the advantages that are generated from the adoption of those techniques, as well as the problems that are connected with integrating AI into supply chain operations. In addition, real-world examples as well as case studies will be provided to highlight how AI has been successfully used in supply chain management. Biryanis et al (2018)

2. Objective

The research aimed to fulfill the following objectives:

· AI-based forecasting

· benefits of incorporating AI into the decision-making and forecasting processes of supply chains

· Result and discussion

3. Methodology

The use of artificial intelligence (AI) in supply chains has the potential to change forecasting and decision-making by providing businesses with the ability to leverage the power of data and analytics. Not only does this improve operational efficiency, but it also increases customer happiness, lowers costs, and generates competitive advantage. It is anticipated that as AI continues to improve, it will transform supply chain operations, therefore helping businesses to react to the more complex and volatile business environment. In the next sections, we will investigate the particular uses of artificial intelligence in supply chain forecasting, demand planning, inventory management, and decision-making. In addition to this, we will talk about the advantages and difficulties related with the use of AI technology. Organizations may strategically exploit these technologies to obtain a competitive advantage in the market if they have a good knowledge of the potential of artificial intelligence to revolutionize supply chain operations.

4. benefits of incorporating AI into the decision-making and forecasting processes of supply chains

The following are some benefits of incorporating AI into the decision-making and forecasting processes of supply chains:

The accuracy of forecasts may be improved by the use of AI methods such as machine learning algorithms, which can examine vast amounts of historical data in order to recognize patterns, trends, and seasonality. This allows more precise demand forecasting, which in turn helps to reduce mistakes in forecasting and improves inventory planning. Forecasting models that are based on AI continually learn and adapt to changing market circumstances, which leads to more accurate and dependable forecasts.

AI helps businesses to record and analyze real-time data, including consumer behavior, market trends, and external variables. This contributes to improved demand planning. This technique, which is powered by data, makes it possible to sense demand, which in turn enables businesses to react swiftly to changes in client demand and to adapt their production and inventory plans appropriately. Luke (2011)AI also enables individualized demand planning, which enables businesses to better allocate their resources by catering their products and services to the specific tastes of each individual consumer.

AI algorithms may improve inventory levels by taking into consideration a number of different aspects, including demand fluctuation, lead times, and supply chain restrictions. Artificial intelligence can recognize trends in inventory and provide recommendations for the best ways to refill it using predictive analytics. This helps cut down on both stockouts and surplus inventory. As a result, this results in cost reductions, improved management of working capital, and enhanced overall supply chain efficiency.

AI helps proactive decision-making by giving real-time insights and suggestions, which are then used in the decision-making process. Analytics systems that are driven by AI are able to do data analysis on information gathered from a variety of sources, determine the potential for supply chain risks or disruptions, and provide solutions. This enables firms to make well-informed choices in advance, therefore reducing the negative effects of interruptions and increasing the supply chain's resilience. Forecasting in Decision-Making Support Systems (2017)

Enhanced Customer Service: Organizations are able to enhance order fulfillment rates and decrease delivery delays if demand is properly forecasted and inventory levels are optimized. Customers will have a better overall experience because to the individualized advice and services that can be provided by AI-driven systems, which will also increase customer satisfaction. When a company's delivery is on time and trustworthy, customers are more likely to remain loyal to that company, which is good for the brand's reputation.

The use of AI for forecasting and decision-making may lead to cost savings by lowering the expenses associated with maintaining inventory, limiting the likelihood of stockouts, and enhancing the performance of transportation and logistical operations. Guo and Wong (2013) Increasing an organization's operational efficiency, decreasing the number of mistakes caused by human intervention, and more efficiently allocating resources are all possible outcomes of optimizing the procedures involved in the supply chain and automating repetitive jobs.

Continuous Learning and Adaptability: Artificial intelligence systems may learn and improve over time as they analyze more data and come into contact with different situations. Organizations are able to accomplish continual optimization and respond to shifting market dynamics if they regularly analyze, and then update, their models. This adaptability and flexibility are especially helpful in conditions of high uncertainty and volatility in the corporate world.

Integrating AI into the forecasting and decision-making processes of a supply chain brings numerous benefits, including improved forecasting accuracy, improved demand planning, optimized inventory management, proactive decision-making, enhanced customer service, cost savings, and continuous improvement. Putting artificial intelligence to work for a business may help it achieve a competitive advantage, improve the efficiency of its supply chain operations, and better satisfy the expectations of its customers. Woodhead Publishing series in textiles (2013)

5. AI-based forecasting

In AI-based forecasting, data preparation and feature selection are two essential steps:

In artificial intelligence-based demand forecasting, data preparation and feature selection play an essential role. During these stages, the raw data are converted into a format that is more conducive to analysis, and then key attributes that are important to making accurate predictions are selected. After the data have been preprocessed, machine learning techniques are used to the information in order to construct forecasting models. The following is a list of the most important things to keep in mind while selecting features and doing data preparation for AI-based demand forecasting:

Cleaning the data entails locating and dealing with any missing numbers, outliers, or discrepancies that may be present in the collected information. Imputation methods such as mean imputation and regression-based imputation may be used to fill in the blanks left by missing data. It is possible to identify outliers and then either get rid of them or handle them independently. Inconsistencies in the data, such as contradicting information or mistakes in data input, need to be rectified in order to assure the quality of the data.

Transformation of Data: Methods of data transformation are used in order to normalize or standardize the data in order to prepare it for usage with machine learning algorithms. Scaling the data to a given range (for example, using Min-Max scaling) or altering it such that it follows a Gaussian distribution (for example, using logarithmic transformation) are both common procedures. These adjustments guarantee that the data are all on the same scale and that they correspond to the assumptions of the forecasting method that was selected. Wong and Guo (2013)

Engineering Features: The process of engineering features includes either the creation of new features or the modification of existing features in order to collect essential data for demand forecasting. This might contain time-based characteristics (for example, day of the week or seasonality), lagged variables (for example, past sales), rolling statistics (for example, moving averages), or domain-specific features (for example, promotions or weather data). The goal of feature engineering is to accurately estimate future demand by identifying and capturing patterns and correlations in the data that are significant to that prediction.

The process of determining which characteristics are the most instructive and pertinent with regard to demand forecasting is referred to as "feature selection." This stage helps limit the number of dimensions and focuses on the factors that have the greatest influence, so reducing noise or information that is redundant. Several methods, such as statistical testing, correlation analysis, or model-based feature selection algorithms (for example, LASSO and Recursive Feature Elimination), are all viable options that might be used. Model performance may be improved by the use of feature selection, which also helps to avoid overfitting and increase interpretability.

Preparation of Time Series Data Demand forecasting often incorporates time series data, which calls for special factors to be taken into account. temporal series data must be formatted with an appropriate temporal granularity (for example, daily or weekly), and it may be necessary to do extra preprocessing processes such as differencing in order to eliminate trends or seasonal patterns in the data. In addition, the data may need to be segmented into a training set and a testing set, with the time dimension in mind, in order to carry out an accurate model assessment.

Handling Categorical Variables: If the dataset contains categorical variables (such as product categories or customer segments, for example), then the necessary encoding methods need to be employed in order to turn those variables into numerical form so that they may be analyzed. Depending on the characteristics of the data and the particular machine learning algorithm that is being used, this step may include one-hot encoding, label encoding, or target encoding. Copyright (2013)

Following the completion of the procedures involving the preprocessing of data and the selection of features, it is possible to use machine learning algorithms in order to construct demand forecasting models. Linear regression, decision trees, random forests, support vector machines (SVM), and more sophisticated approaches such as recurrent neural networks (RNN) or gradient boosting algorithms are examples of popular algorithms used for demand forecasting. more popular methods include support vector machines (SVM).

The accuracy of the forecasting models is not only dependent on the particular machine learning algorithm that is used, but also on the standard of the data that is preprocessed as well as the characteristics that are considered to be pertinent. It is possible for businesses to increase the accuracy and reliability of the demand forecasting models they use based on AI by doing meticulous preprocessing on the data and identifying important characteristics. Woodhead Publishing series in textiles (2013)

Figure 1

|

Figure 1 Ai and

Supply Chain Planning |

6. RESULT AND DISCUSSION

Artificial intelligence (AI) has tremendous potential to completely transform supply chain operations, especially in the areas of forecasting and decision-making. Organizations have been able to increase their forecasting accuracy, optimize their inventory management, and make proactive choices by employing AI methods including machine learning, natural language processing, and predictive analytics.

Artificial intelligence (AI) based forecasting models have been shown to be more accurate than more conventional approaches. Large datasets may be analyzed by machine learning algorithms to reveal patterns and capture complicated interactions between the many elements that affect consumer demand. This allows businesses to better manage their inventories and production by making more precise projections and experiencing fewer forecasting mistakes. Wong and Guo (2013)

Artificial intelligence (AI) helps businesses improve their demand planning by using real-time data and cutting-edge analytics. In order to detect shifts in demand, demand sensing methods take into account real-time market data, client behavior, and external influences. As a result, businesses are better able to optimize their supply chains, plan production, and handle inventories using hard data.

By taking into account demand unpredictability, lead times, and supply chain restrictions, AI-driven approaches aid in optimizing inventory management. Predictive analytics can find trends in stock and advise on the best ways to restock, which helps cut down on waste and keeps stock-outs to a minimum. As a result, expenses are reduced, working capital management is enhanced, and the supply chain runs more smoothly.

Decisions may be made in advance with the help of AI since it provides timely information and advice. Multi-source data analysis, anomaly detection, and supply chain risk/disruption detection are all possible with AI-powered analytics solutions. This allows businesses to strengthen their supply chains by taking preventative actions and minimizing interruptions before they occur.

Improved Customer Support: Predictive analytics and AI-based decision making can improve customer support. In order to avoid stockouts and increase order fulfillment rates, it is important to accurately predict future demand. Businesses may increase customer happiness by using AI-driven personalization to provide individualized services and suggestions. Introduction to Artificial Intelligence-Based Decision Making (2015)

Financial savings and increased productivity result from using AI for supply chain planning and decision-making. Organizations may save money on storage fees and guarantee sufficient supply by maintaining optimal inventory levels. Automation and simplification of supply chain operations powered by AI reduces the likelihood of human mistake and maximizes the use of available resources, hence boosting operational efficiency and saving money.

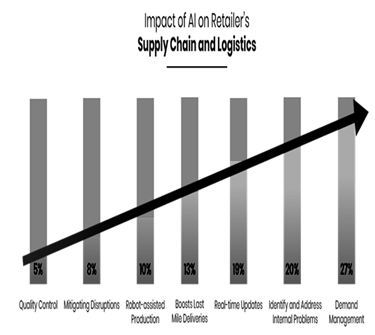

Figure 2

|

Figure 2 Ai and

Supply Chain Planning |

7. CONCLUSION

The incorporation of AI into the forecasting and decision-making processes of supply chains provides a wide variety of advantages; nonetheless, there are obstacles to be addressed. Considerations about the quality of the data, its availability, and its integration across the many systems continue to be essential. To guarantee the precision and dependability of artificial intelligence models, companies will need to make investments in data infrastructure, data governance, and data management techniques. In addition to this, the organizational preparation, change management, and ethical issues around AI-driven decision-making should be addressed. In conclusion, the use of AI in the forecasting and decision-making processes of supply chain operations has been shown to have game-changing implications on supply chain operations. The use of AI methods results in improved accuracy of forecasting, optimization of demand planning and inventory management, the ability to make proactive decisions, improved customer service, and cost savings. However, in order for the implementation to be effective, it is necessary to overcome difficulties connected to data and ensure organizational preparedness. As artificial intelligence continues to progress, businesses may take use of its capabilities to gain a competitive edge and adapt to the rapidly shifting terrain of the business world.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Biryanis, G., Dani, S., Valid, S., & Antoniou, G. (2018). Decision Support Systems and Artificial Intelligence in Supply Chain Risk Management. In Springer Series in Supply Chain Management (pp. 53–71). Springer. https://doi.org/10.1007/978-3-030-03813-7_4

Butcher, T., & Grant, D. B. (2012). Identifying Supply Chain Value Using RFID-Enabled Distributed Decision-Making for Food Quality and Assurance. In Decision-Making for Supply Chain Integration (pp. 89–103). Springer. https://doi.org/10.1007/978-1-4471-4033-7_5

Copyright. (2013). In Optimizing Decision Making in the Apparel Supply Chain using Artificial Intelligence (AI) (p. iv). Woodhead Publishing. https://doi.org/10.1016/B978-0-85709-779-8.50012-3

Forecasting in Decision-Making Support Systems. (2017). Modeling of Artificial Intelligence, 4(2), 93–97. Https://Doi.Org/10.13187/mai.2017.2.93

Guo, Z. X., & Wong, W. K. (2013). Fundamentals of Artificial Intelligence Techniques for Apparel Management Applications. In Optimizing Decision Making in the Apparel Supply Chain Using Artificial Intelligence (AI) (pp. 13–40). Woodhead Publishing. https://doi.org/10.1533/9780857097842.13

Introduction to Artificial Intelligence-Based Decision Making. (2015). In Causality, Correlation and Artificial Intelligence for Rational Decision Making (pp. 1–21). World Scientific. https://doi.org/10.1142/9789814630870_0001

Luke, P. (2011). Fuzzy Similarity in Multicriteria Decision-Making Problem Applied to Supplier Evaluation and Selection in Supply Chain Management. Advances in Artificial Intelligence, 2011, 1–9. https://doi.org/10.1155/2011/353509

Wong, W. K. (2013). Understanding Key Decision Points in the Apparel Supply Chain. In Optimizing Decision Making in the Apparel Supply Chain Using Artificial Intelligence (AI) (pp. 1–12). Woodhead Publishing. https://doi.org/10.1533/9780857097842.1

Wong, W. K., & Guo, Z. X. (2013). Intelligent Sales Forecasting for Fashion Retailing Using Harmony Search Algorithms and Extreme Learning Machines. In Optimizing Decision Making in the Apparel Supply Chain Using Artificial Intelligence (AI) (pp. 170–195). Woodhead Publishing. https://doi.org/10.1533/9780857097842.170

Woodhead Publishing series in textiles. (2013). In Optimizing Decision Making in the Apparel Supply Chain Using Artificial Intelligence (AI) (pp. ix–xv). Woodhead Publishing. https://doi.org/10.1016/B978-0-85709-779-8.50013-5

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2024. All Rights Reserved.