|

|

|

|

ANALYSIS OF THE EFFECT OF COARSE AGGREGATE PARTIAL SUBSTITUTION WITH GRANITE FRAGMENTS IN THE COMPOSITION OF CONCRETE MIXTURE MATERIALS TOWARD CONCRETE COMPRESSIVE STRENGTH

Taufik Dwi Laksono

1, Dwi Sri Wiyanti

2![]()

1, 2 Civil

Engineering, Faculty of Engineering, Wijayakusuma

University Purwokerto, Jl. Beji Kampus

Karangsalam Purwokerto,

Indonesia

|

|

ABSTRACT |

||

|

The concrete basic composition can be modified by using alternative materials for coarse aggregate, fine aggregate, or modifying the type of sand. In this study, destructive method testing was applied to find the compressive strength of concrete that was mixed with coarse aggregate admixture material from granite waste that was combined with natural aggregate and then compared with normal concrete. The sands added to the mixture originated from the Serayu River and Mount Merapi. To create concrete with a planned quality of fc’ 30 Mpa, three types of test objects are created. The first is unmixed concrete (0% admixture), the second and the third are uses granite waste as coarse aggregate substitution as much as 50%, and 100%. The test

objects were then tested for compressive strength in 7 days and 28 days. The

seven (7) days test showed that maximum compressive strength of 22,23 Mpa was produced by a mixture of Mount Merapi and coarse

aggregate substitution of 50% granite waste. The use of Mount Merapi sand and

Serayu River sand in all substitution compositions

of granite waste shows that concrete compressive strength that uses Mount

Merapi sand is better than in the mixture that uses Serayu

River sand. |

|||

|

Received 15 December 2023 Accepted 16 January 2024 Published 31 January 2024 Corresponding Author Dwi Sri Wiyanti, sriwiyanti2@yahoo.com DOI 10.29121/ijetmr.v11.i1.2024.1400 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2024 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Concrete

Compressive Strength, Coarse Agregate, Granite,

Mount Merapi Sand, Serayu River Sand |

|||

1. INTRODUCTION

Concrete

compressive strength is the number of loads per unit area that broke concrete

test objects when exposed to specific pressing force produced by the press

machine. Compared to the other characteristics, concrete compressive strength

is the most important characteristic of concrete quality. The compressive

strength of concrete is determined by the ratio setting among cement, coarse

aggregate, fine aggregate, and water.

Of the many

conducted concrete tests, the compressive strength test is the most important

because it describes the characteristics of concrete.

Many studies

conducted to get the best quality and compressive strength of concrete. One of

the methods is by modifying the basic mixture of concrete. A basic mixture of

concrete consists of cement, fine aggregate, coarse aggregate, and water. A

basic mixture of concrete can be modified with alternative materials that is

fine aggregate, or by modifying the type of sand as an alternative material.

Hadi (2020) conducted a study on the effect of adding granite waste on concrete compressive strength, the result shows that normal concrete compressive strength is 26.09 Mpa. By adding 8%, 10%, and 12% of granite waste, the compressive strength for each addition is 24.58 Mpa, 22.69 Mpa, and 21.28 Mpa. The addition of granite waste in normal concrete turns out to lessen the concrete compressive strength. The higher the addition percentage the lower the compressive strength of concrete. This study concluded that normal concrete compressive strength is better than concrete.

A study on the effect of using unpolished granite waste as partial coarse aggregate substitution towards K-175 Concrete compressive strength was conducted by Luthful (2023), he used various mixture proportions to find proportion variants that produce the best compressive strength. The variants created are 50% pure material and 50% waste material. The use of 80% waste material and 20% pure material in K-175 concrete achieved the planned quality that meets the concrete mix job.

Zarkasih (2023) conducted a study on granite waste and

zeolite utilization as coarse aggregate substitution and zeolite as cement

substitution in Self Compacting Concrete. The study concluded that using

granite waste as coarse aggregate substitution and zeolite as cement

substitution improves the quality of concrete if applied with the proper

percentage between those two materials.

Wahyu Hudha et al. (2019) conducted a study on High early strength

concrete innovation by utilization of granite waste, clamshell, and fly ash.

The study concluded that innovation concrete is more environmentally friendly

because it uses waste materials that reduce the waste that disrupt

environmental sustainability.

Dominggus et al. (2019) conducted a study on the effect of adding granite tile powder waste on the characteristics of normal concrete. The result shows that concrete with 5% granite powder produces the optimum result of 34.96 MPa compressive strength in 28 days, 2.77 MPa tensile strength, and 35875 MPa elasticity modulus.

Arruna Rodhi

et al. (2021) in the study of the industrial waste

concrete for sustainable development using American Concrete Institute (ACI)

planning method and EFNARC standard created three (3) concrete cylinders with

the size of 15cm x 30cm and one (1) cube with the size of 15cm x 15cm by adding

iron powder as much as 10% of the total fine aggregate, steel slag, and granite

as much as 50% of the total coarse aggregate, marble powder as much as 10% of

the total cement, and Sika Viscocrete 1003 as much as 1,5% were used in Civil

Engineering laboratory of Muhammadiyah Surakarta University with f’cr 45 MPa.

The study is expected to become an innovation of concrete that is more

sustainable, environmentally friendly, efficient, and economical than

conventional concrete.

This study used

a destructive method to test the compressive strength of concrete that mixed

with coarse aggregate addition material from granite waste that was combined

with natural aggregate and then compared with normal concrete. The sand that is

used are the Serayu River and Mount Merapi Sand. The problem of this study is

formulated as follows :

1)

What

is the effect of granite waste as coarse aggregate substitution towards

concrete compressive strength?

2)

How

does the use of Mount Merapi sand compare to the Serayu River sand for normal

concrete and one of concrete mixture types?

Granite waste

is the remainder or fragments from granite mining. By using granite waste, the

researchers aimed to utilize mining waste products properly. Granite was chosen

because it was rarely used and left piled up and scattered around the mining

area.

2. METHODS AND MATERIALS

In conducting a

study of concrete compressive strength observation on the mixture composition

towards concrete mixture materials, the materials that being used are :

1) Coarse aggregate from granite waste

According to

SNI-03-2847-2002, coarse aggregate is gravel formed from the natural

disintegration of rock or crushed stone produced by the stone-crushing industry

and has a grain size between 5mm and 40mm. For the gravels to be used, the

following conditions must be fulfilled :

· Permanent non-porous hard grain, which means it is not broken by weather influences such as sunlight and rain.

· Not contain more than 1% of mud, if the mud exceeds 1% then it should be washed before use.

· Not contain substances that can damage rock such as substances that are reactive to alkali.

· Flat-grain coarse aggregate can only be used if the amount is not more than 20% of the total weight.

According to Tjokrodimuljo (1996), aggregate characteristics that most

influence concrete strength are surface roughness and maximum size. Aggregate

with a rough surface will form a good bond between the cement paste and the

aggregate. Aggregate with bigger size has a more narrow surface area so that

the bond with cement paste is reduced. Coarse aggregate holds an important role

in producing good concrete compressive strength. Wet stones such as mountain

stones and river stones are coarse aggregates that are commonly used in

concrete mixtures.

Granite is

commonly used as a material to improve the aesthetic aspect of a building.

Granite itself has better strength than wet stone. The granite industry that

processes granite chunks to become granite slabs usually produces quite a lot

of waste in the form of granite fragments. Therefore, these granite fragments

will be utilized as concrete mixture material.

In Baseh

Village, Kedungbanteng District of Banyumas Regency, Central Java there is a

granite processing industry. Granite mining produces residual waste that is

left to pile up in the mining area. Based on the good characteristics of

granite, this stone is very suitable to be used as a coarse aggregate

substitution in concrete mixture. Therefore, it is necessary to conduct a study

on concrete that uses granite as coarse aggregate in a concrete mixture by

utilizing granite waste remainder as coarse aggregate substitution with a

maximum gradation of 20 mm.

2) Fine Aggregate

Fine aggregate

is natural sand from natural disintegration or stone produced by the stone

crusher industry that has a grain size of 5mm (passing through no.4 filter)

(SNI 03-2834-2000) or river sand from the river bottom. This sand generally has

fine and round grains due to the friction process. The fine aggregates used are

Mount Merapi sand from Muntilan Magelang and Serayu River sand. On fine

aggregate, tests were carried out on sieve analysis, content weight, water

absorption, and density.

3)

Coarse aggregate

The coarse

aggregate used in this study originated from a stone crusher in Rawalo,

Banyumas Regency with a maximum gradation of 20 mm.

4)

Cement

Cement as a

concrete mixture material is a hydraulic-inorganic adhesive in the form of fine

powder that has chemical bonding characteristics (adhesive and cohesive) and

can form a new compound (paste to solid) if reacted with water in a particular

time, on the other hand, Portland cement is the cement that contains calcium,

silicate, aluminate, and ferrite compounds with some other additive materials.

The cement that was used was Portland Cement Composite (PCC) type with Gresik

brand.

5)

Water

The

requirements of water used for the concrete mixture are :

· Must not contain more than 2 grams/liter of mud or other flying objects

· Must not contain substances that can harm concrete (acid, organic substance, etc)

· Must not contain more than 0,5 grams/liter of chloride (Cl).

· Must not contain more than 1gram/liter of sulfate compounds.

In a concrete mixture, water is added in ratio with cement

or fas. The requirement to hydrate cement is 1 (one)

portion of cement needs 0,25 portion of water weight. Concrete

that contains low water proportion will make the mixture very dry and hard to

solidify, an extra addition of water is needed to lubricate the mixture so that

it can be processed. On the other hand, if all water evaporates when the

concrete dries it will create pores. Therefore, it is important to maintain the

water proportion as minimal as possible

The water that

is used is clean water that does not contain mud or oil and other substances

that can harm concrete. The water originated from the Structure Engineering

Laboratory of the Engineering Faculty of Wijayakusuma University.

A study on

granite waste utilization as coarse aggregate substitution and the use of Mount

Merapi and Serayu River sand is conducted with the following conditions :

· The mix design used the SNI 03-2834-2000 method which is about the procedure of normal concrete mixture planning.

· Maximum coarse aggregate gradation is 20mm, the coarse aggregate originated from the Serayu River in Patikraja, Banyumas Regency.

· The granite waste originated from Baseh Village, Kedungbanteng District, Banyumas Regency, Central Java Province.

· The percentage of granite waste as coarse aggregate substitution is 0%, 50%, and 100%.

· The sand originated from Mount Merapi and Serayu River.

· The quality of concrete that was used was fc’ 30Mpa.

· Concrete testing carried out includes slump flow testing and compressive strength testing.

· The dosage of Sika ViscoCrete-3115N additive substance is 1,5% of cement weight.

· There are 3 samples each for 7 days testing and 28 days testing.

· Using Portland Cement, a PCC with Gresik brand.

· The test object is cylindrical with 15 cm diameter and 30 cm height.

This study is conducted by creating a test object in the Structural Engineering Laboratory. There are 3 (three) types of test objects in creating concrete with a plan quality of fc’ 30 Mpa. The first test object is concrete without admixture (0%), and the second and the third test objects use 50% and 100% of granite waste as coarse aggregate substitution. Then, the test objects are tested by compressive strength for 7 and 28 days. From the result of this study, it is expected that we find out the effect of granite waste as coarse aggregate substitution and zeolite as cement substitution towards concrete compressive strength

3. RESULT AND DISCUSSION

The creation of

test object variations was determined as listed in the following Table 1 :

Table 1

|

Table 1 Test Object Variations |

||||

|

No |

Variations |

Test

Object Code |

7 days

Compressive Strength Testing |

28 days

Compressive Strength Testing |

|

1 |

Normal

concrete, Mount Merapi sand |

BN 1 |

3 |

3 |

|

2 |

Normal

concrete, Serayu River sand |

BN 2 |

3 |

3 |

|

3 |

Concrete

with Mount Merapi sand and 50% granite waste as coarse aggregate substitution |

BG 1 |

3 |

3 |

|

4 |

Concrete

with Serayu River sand and 50% granite waste as coarse aggregate substitution |

BG 2 |

3 |

3 |

|

5 |

Concrete

with Mount Merapi sand and 100% granite waste as coarse aggregate

substitution |

BG 3 |

3 |

3 |

|

6 |

Concrete

with Serayu River sand and 100% granite waste as coarse aggregate

substitution |

BG 4 |

3 |

3 |

After the test object samples are made, treatment and

compressive strength tests using cylindrical concrete with 15 cm diameter and

30 cm height are carried out.

The results of compressive strength calculation of 0% granite waste mixture with the addition of sika vicocrete 3115N as much as 1,5% of cement weight in 7 and 28 days can be seen in Table 2, Table 3, Table 4, and Table 5.

Table 2

|

Table 2 Results of Compressive Strength Calculation of 7 Days Old BN 1 Concrete |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

|

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

|

1 |

BN 1 – 1 |

12,850 |

374.000 |

17.662,5 |

21.17 |

|

2 |

BN 1 – 2 |

12,950 |

368.000 |

17.662,5 |

20.83 |

|

3 |

BN 1 – 3 |

12,950 |

383.000 |

17.662,5 |

21.68 |

|

Average Compressive Strength |

21.23 |

||||

Table 3

|

Table 3 Results of Compressive Strength Calculation

of BN 1 Concrete Aged 28 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum

Load (P) |

Compression

Area (A) |

Compressive

Strength |

|

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

|

|

1 |

BN 1 –

1 |

12,900 |

574.000 |

17.662,5 |

32.52 |

|

2 |

BN 1 –

2 |

12,800 |

544.000 |

17.662,5 |

30.84 |

|

3 |

BN 1 –

3 |

12,850 |

594.000 |

17.662,5 |

33.65 |

|

Average

Compressive Strength |

32.34 |

||||

Table 4

|

Table 4 Results of Compressive Strength Calculation of BN

2 Concrete Aged 7 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BN 2 – 1 |

12,650 |

370.000 |

17.662,5 |

20.94 |

|

2 |

BN 2 – 2 |

12,650 |

375.000 |

17.662,5 |

21.23 |

|

3 |

BN 2 – 3 |

12,700 |

362.000 |

17.662,5 |

20,55 |

|

Average Compressive Strength |

20,90 |

||||

Table 5

|

Table 5 Results of Compressive Strength Calculation of

BN 2 Concrete, Aged 28 Days |

|||||

|

No |

Test

Object Code |

Weight |

Maximum

Load (P) |

Compression

Area (A) |

Compressive

Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BN 2 –

1 |

12,650 |

535.000 |

17.662,5 |

30.29 |

|

2 |

BN 2 –

2 |

12,600 |

515.000 |

17.662,5 |

29.16 |

|

3 |

BN 2 –

3 |

12,650 |

557.000 |

17.662,5 |

32.52 |

|

Average

Compressive Strength |

30.52 |

||||

Result of Compressive Strength Calculation of 7 days old BN 1 Concrete

The results of compressive strength calculation of 50%

granite waste mixture with the addition of sika vicocrete 3115N

as much as 1,5% of cement weight in 7 and 28 days can be seen in Table 6, Table 7, Table 8, and Table 9.

Table 6

|

Table 6 Results of Compressive Strength Calculation of

BG 1 Concrete, Aged 7 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BG 2 – 1 |

12,700 |

390.000 |

17.662,5 |

22.08 |

|

2 |

BG 2 – 2 |

12,650 |

404.000 |

17.662,5 |

22.87 |

|

3 |

BG 2 – 3 |

12,650 |

387.000 |

17.662,5 |

21.74 |

|

Average Compressive Strength |

22.23 |

||||

Table 7

|

Table 7 Results of Compressive Strength Calculation of

BG 1 Concrete, Aged 28 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BG 1 – 1 |

12,750 |

515.000 |

17.662,5 |

29.16 |

|

2 |

BG 1 – 2 |

12,750 |

547.000 |

17.662,5 |

30.97 |

|

3 |

BG 1 – 3 |

12,700 |

540.000 |

17.662,5 |

30.57 |

|

Average Compressive Strength |

30.23 |

||||

Table 8

|

Table 8 Results of Compressive

Strength Calculation of BG 2 Concrete, Aged 7 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

|

|

1 |

BG 1 –

1 |

12,800 |

354.000 |

17.662,5 |

20.04 |

|

2 |

BG 1 –

2 |

12,800 |

341.000 |

17.662,5 |

19.3 |

|

3 |

BG 1 –

3 |

12,750 |

367.000 |

17.662,5 |

20.77 |

|

Average

Compressive Strength |

20.03 |

||||

Table 9

|

Table 9 Results of Compressive

Strength Calculation of BG 2 Concrete, Aged 28 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

|

|

1 |

BG 2 – 1 |

12,650 |

506.000 |

17.662,5 |

28.65 |

|

2 |

BG 2 – 2 |

12,600 |

583.000 |

17.662,5 |

27.35 |

|

3 |

BG 2 – 3 |

12,650 |

523.000 |

17.662,5 |

29.61 |

|

Average Compressive Strength |

28.54 |

||||

The results of compressive strength

calculation of a mixture of 100% granite with the addition of sika vicocrete

3115N as much as 1,5% of cement

weight in 7 and 28 days can be seen in Table 10, Table 11, Table 12, and Table 13.

Table 10

|

Table 10 Results of Compressive Strength Calculation of

BG 3 Concrete Aged 3 and 7 Days |

|||||

|

No |

Test

Object Code |

Weight |

Maximum

Load (P) |

Compression

Area (A) |

Compressive

Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BG 3 –

1 |

12,450 |

356.000 |

17.662,5 |

20,16 |

|

2 |

BG 3 –

2 |

12,500 |

342.000 |

17.662,5 |

19,70 |

|

3 |

BG 3 –

3 |

12,450 |

356.000 |

17.662,5 |

20,16 |

|

Average

Compressive Strength |

20,02 |

||||

Table 11

|

Table 11 Results of Compressive Strength Calculation of

BG 3 Concrete Aged 28 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BG 3 – 1 |

12,500 |

483.000 |

17.662,5 |

27,35 |

|

2 |

BG 3 – 2 |

12,400 |

471.000 |

17.662,5 |

26,67 |

|

3 |

BG 3 – 3 |

12,500 |

483.000 |

17.662,5 |

27,35 |

|

Average Compressive Strength |

27,12 |

||||

Table 12

|

Table 12 Results of Compressive Strength Calculation of

BG 3 Concrete Aged 7 Days |

|||||

|

No |

Test Object Code |

Weight |

Maximum Load (P) |

Compression Area (A) |

Compressive Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BG 3 – 1 |

12,400 |

348.000 |

17.662,5 |

19,70 |

|

2 |

BG 3 – 2 |

12,500 |

342.000 |

17.662,5 |

19,70 |

|

3 |

BG 3 – 3 |

12,450 |

356.000 |

17.662,5 |

20,16 |

|

Average Compressive Strength |

19,74 |

||||

Table 13

|

Table 13 Results of Compressive

Strength Calculation of BG 4 Concrete Aged 28 Days |

|||||

|

No |

Test Object

Code |

Weight |

Maximum

Load (P) |

Compression

Area (A) |

Compressive

Strength |

|

(Gram) |

(N) |

(mm²) |

(Mpa) |

||

|

1 |

BG 3 –

1 |

12,500 |

483.000 |

17.662,5 |

27,35 |

|

2 |

BG 3 –

2 |

12,400 |

471.000 |

17.662,5 |

26,67 |

|

3 |

BG 3 –

3 |

12,400 |

471.000 |

17.662,5 |

26,67 |

|

Average

Compressive Strength |

26,90 |

||||

The

average results of compressive strength

testing of all test objects can be seen in the following Table 14:

Table 14

|

Table 14 Average Results of Concrete Compressive Strength Tests |

|||

|

No |

Test Object Code |

Average Result of

Compressive Strength Testing (Mpa) |

|

|

|

|

7 days |

28 days |

|

1 |

BN 1 (Mount Merapi sand + 0 % granite) |

21,23 |

32,34 |

|

2 |

BN 2 (Serayu River sand + 0 % granite) |

20,90 |

30,52 |

|

3 |

BG 1 (Mount Merapi sand + 50 % granite) |

22,23 |

30,23 |

|

4 |

BG 2 (Serayu River sand + 50% granite) |

20,03 |

28,54 |

|

5 |

BG 3 (Serayu River sand + 100 % granite) |

20,02 |

27,12 |

|

6 |

BG 4 (Mount Merapi sand + 100 % granite) |

19,74 |

26,90 |

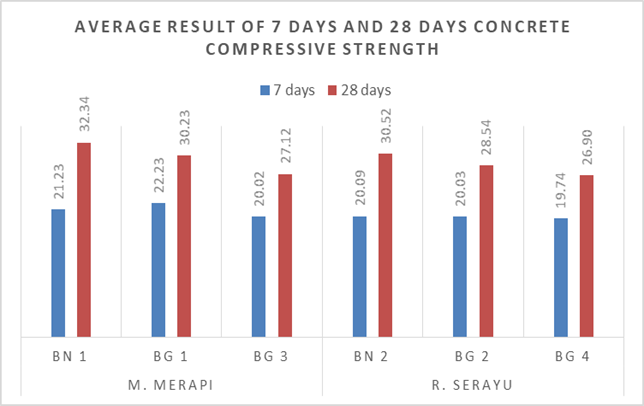

Overall comparison of the

compressive strength test of concrete with granite waste as coarse aggregate

substitution, the mixture of Mount Merapi and Serayu River sand, and addition

of 1,5% sika ViscoCrete-3115N can be seen in Figure 1 and Figure 2 as follows:

Figure 1

|

Figure

1 Average Results of 7 Days and 28 Days Concrete

Compressive Strength. |

At the age of 7 days, the maximum concrete compressive

strength achieved by BG 1 mixture is 22,23 Mpa. The decline of compressive

strength occurred in BG2, BG 3, and BG 4 variations. Meanwhile, at the age of

28 days, the maximum concrete compressive strength achieved by the BN 1 mixture

is 32,34 MPa and the decline of compressive strength occurred in BN2, BG 1, BG

2, BG 3, and BG 4 variations.

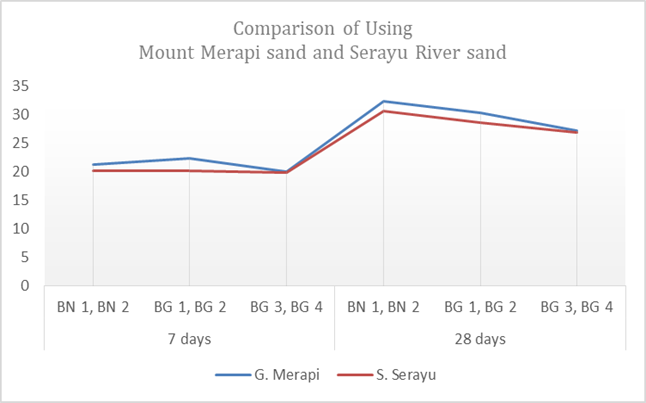

Figure 2

|

Figure

2

Comparison of Using Mount Merapi Sand and Serayu

River Sand. |

A comparison of using Mount Merapi sand and Serayu River

sand produces different concrete compressive strength. The use of Mount Merapi

sand in BN 1, BG 1, and BG 3 variations produces bigger compressive strength

than Serayu River sand in BN 2, BG 2, and BG 4, both at the age of 7 days and

28 days.

4. CONCLUSIONS

The Study of

the Compressive Strength of Concrete that adds granite waste as coarse

aggregate and the use of Serayu River sand and Mount Merapi sand can be

concluded as follows :

1)

From the results of the concrete compressive

strength test which aged 7 days, the maximum concrete compressive strength of

22,23 MPa is achieved by the mixture of Mount Merapi sand with 50% granite

waste as coarse aggregate substitution. The decline of compressive strength

occurred in the mixture of Serayu River sand with 50% granite waste as coarse

aggregate substitution and the mixture of Mount Merapi sand with 100% granite

waste as coarse aggregate substitution. On the other hand, in the concrete

compressive strength test which aged 28 days, the maximum compressive strength

was produced by normal concrete, the decline of compressive strength occurred

on all other variations with the addition of Mount Merapi sand, Serayu River

sand, 50% of granite waste and 100% of granite waste.

2) A comparison of the use of Mount Merapi sand and Serayu River sand in all granite waste substitution compositions shows that the concrete compressive strength of the mixture that uses Mount Merapi sand is greater than the concrete compressive strength that uses Serayu River sand, both on the 7 days and 28 days compressive strength test.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Arruna Rodhi, P., Fadhilah, A., & Rizfira, Y.T.M. (2021). Beton Sisa Industri for Sustainable Development. Jurnal Bangunan, 26(2), 47–62. http://dx.doi.org/10.17977/um071v26i22021p47-62.

Badan Standarisasi Nasional. (1990). Metode Pengujian Tentang Analisis Saringan Agregat Halus Dan Kasar.

Badan Standarisasi Nasional. (2000). Tata Cara Rencana Pembuatan Campuran Beton Normal.

Badan Standarisasi Nasional. (2002). Metode Pengujian Kuat Tarik Belah Beton.

Badan Standarisasi Nasional. (2004). Semen Portland.

Badan Standarisasi Nasional. (2008). Cara Uji Keausan Agregat Dengan Mesin Abrasi Los Angles.

Badan Standarisasi Nasional. (2011). Tata Cara Pembuatan Dan Perawatan Benda Uji.

Bakarbessy, D., & Krisna, W. (2019). Efek Penambahan Limbah Bubuk Granit Lantai Terhadap Karakteristik Beton Normal. Jurnal PORTAL SIPIL, 8(2), 29-37.

Hadi, S. (2020). Pengaruh Penambahan Limbah Granit Terhadap Kuat Tekan beton. Journal Unmasmataram, 14(1), 476 – 480. https://doi.org/10.35327/gara.v14i1.123.

Luthful, M. (2023). Pengaruh Penggunaan Limbah Granit Unpolish SEbagai Pengganti Sebagian Agregat Kasar Terhadap Nilai Kuat Tekan Beton K – 175, Skripsi thesis, Fakultas Teknik dan Ilmu Komputer Teknik Sipil.

Tjokrodimuljo, K. (1996). Teknologi Beton.

Wahyu Hudha, P., Seno Darma, S., & Claudia Stefani. S. (2019). Inovasi High Early Strength Concrete dengan Pemanfaatan Limbah Batu Granit, Cangkang Kerang, dan Fly Ash. Jurnal Proyek Teknik Sipil, 2(2), 24–30.

Wang, C. K., Salmon, C. G., & Hariandja, B. (1990). Desain Beton Bertulang. Gelora Aksara Pratama.

Zarkasih, F. (2023). Pemanfaatan Limbah Batu Granit Sebagai Substitusi Agregat Kasardan Material Zeolit Sebagai Substitusi Semen pada Beton SCC, Tugas Akhir Teknik Sipil UNWIKU.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2024. All Rights Reserved.