|

|

|

|

NEURO-FUZZY INTELLIGENT CONTROLLER FOR LFC OF A FOUR-AREA POWER SYSTEM

Basavarajappa Sokke Rameshappa

1 ![]()

![]() , Nagaraj Mudakapla Shadaksharappa 1

, Nagaraj Mudakapla Shadaksharappa 1 ![]()

![]()

1 Department of Electrical and

Electronics Engineering, Bapuji Institute of

Engineering and Technology, Davanagere, VTU,

Belagavi, India

|

|

ABSTRACT |

||

|

In modern

complex power systems, the problem of automatic generation control arises due

to a sudden increase or decrease in load. This problem leads to instability

in the system if the frequency control is not automatic, which may finally

lead to system collapse. Hence, automatic control of frequency and tie-line

power is significant. This research paper develops and compares the

performance of an adaptive neuro-fuzzy inference system (ANFIS) controller

with the conventional PID controller and the Takagi-Sugeno-Kang

fuzzy logic controller for load frequency control (LFC) of a four-area power

system with generation rate constraint (GRC) on turbines. The performance is

compared in terms of errors, settling time and maximum undershoot of the

frequency deviation for different step load changes using Matlab.

The proposed ANFIS controller performs with less peak undershoot of - 0.7374

Hz and a settling time of 27.9823 sec at a 4% change in load. It reduces the

steady-state error to zero. Thus, the proposed controller is the most

suitable LFC in energy centers. The system parameters are taken from the IEEE

press, and EPRI published books. |

|||

|

Received 27 August 2022 Accepted 28 September 2022 Published 13 October 2022 Corresponding Author Basavarajappa Sokke Rameshappa, basavarajsr@gmail.com

DOI 10.29121/ijetmr.v9.i10.2022.1235 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Automatic Load

Frequency Control, ANFIS Controller, Conventional Controller, Power System, Sugeno Fuzzy Logic Controller |

|||

1. INTRODUCTION

An automatic load

frequency control is essential to maintain system stability in complex power system

operations. It is possible by controlling the system frequency and the power

flows in tie-lines, which are at nominal values for small perturbations in

demand Kundur (1994). An automatic LFC in the power system

reduces the area control error (ACE). ACE is the summation of the tie-line

power and system frequency deviation. The speed changer position of the

governor is adjusted using a servo-motor mechanism in the secondary loop of the

control area. The drawbacks of conventional PID controllers are – slow response

and high undershoot/overshot in the ACE. Artificial Intelligent (AI)

controllers can overcome these drawbacks.

In Shaker et al. (2019), an adaptive LFC for a single area using ANFIS

and an artificial intelligence technique is employed. The genetic algorithm is

used to tune the PID controller. A three-area interconnected power system with

fuzzy logic self-tuned PID controller is employed for LFC problems. A

hybrid neuro-fuzzy-based ANFIS controller and robust fuzzy logic-based

fine-tuning approach are proposed for frequency control in a three-area

hydrothermal system Khezri et al. (2016). An ANFIS approach is proposed for LFC in a

multi-area power generation system, and its performance is compared with

conventional controllers Prakash and Sinha (2017). A distributed model predictive LFC for a

four-area hydrothermal power system is proposed. The controller is designed

based on optimal control theory Zhang et al. (2017). A multi-source power system's

automatic LFC with the ANFIS approach is presented considering GRCs and other

non-linearity Bhaskar et al. (2018).

The research work

in the literature employs hybrid techniques combining conventional and

artificial intelligent controllers without GRC to minimize the ACE. It also

employs predictive model control and ANFIS approach with GRC but does not

provide several epochs, optimization techniques, and dynamics of steam

turbines. Hence, the present research proposes an ANFIS controller that uses

ACE and the derivative of ACE to train the model for the LFC system with steam

turbine dynamics, GRC, hybrid, and backpropagation optimization techniques.

2. MATERIALS AND METHODS

2.1. DEVELOPMENT OF THE POWER SYSTEM MODEL

The dynamic mathematical models of various components of power plants were presented in IEEE: Power and Energy Society. (2013). For thermal plants, a governor's transfer function (TF) model is derived from the fundamental speed governor operation as given in Equation 1.

The TF models of a single reheat, tandem compound steam turbine, are obtained from the turbine dynamics as given in Equation 2, Equation 3, Equation 4, for the turbine, reheater, and crossover.

For a nuclear plant, the TF model of a speed governor is derived as given in Equation 5.

The TF models of a double reheat tandem compound steam turbine are obtained from the turbine dynamics as given in Equation 6, Equation 7, Equation 8, for the turbine, reheater, and crossover, respectively.

For a hydropower plant, the TF model of a hydro governor is derived as given in Equation 9.

The TF model of a hydro turbine [3] is obtained from the turbine dynamics, as given in Equation 10.

where ![]() =

hydro governor reset or washout time constant.

=

hydro governor reset or washout time constant. ![]() =

hydro governor temporary droop.

=

hydro governor temporary droop.

The presence of GRC in the system affects stability Sahin (2020). The GRCs for all areas are included by adding the limiters to the turbines. The alternator and load TF model is obtained from the Swing equation as given in Equation 11.

where ![]() =

mechanical power,

=

mechanical power, ![]() = electrical power, and

= electrical power, and ![]() = acceleration power.

= acceleration power.

Equation 11 can be written in the standard form is obtained as given in Equation 12.

![]() , for

i = 1, 2, 3, 4. Equation

12

, for

i = 1, 2, 3, 4. Equation

12

In the system operation, the power flow on the tie-lines is given in Equation 13.

The deviation in tie-line power flow is derived from the power angle equation as Equation 14

ACE is the error signal fed to the controller and is derived as, the combination of the change in tie-line power and system frequency, given in Equation 15.

![]() for i, j = 1, 2, 3, 4. Equation 15

for i, j = 1, 2, 3, 4. Equation 15

The integral of time-weighted absolute error (ITAE) is considered an objective function and is calculated as given in Equation 16.

![]() for

i, j = 1, 2, 3, 4. Equation 16

for

i, j = 1, 2, 3, 4. Equation 16

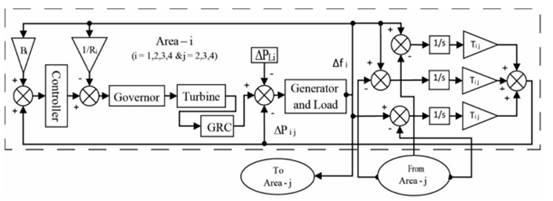

Figure 1 shows the connection of the various components of ith area in a four-area multi-source power system. This system comprises a hydro, a nuclear, and two thermal power plants.

Figure 1

|

Figure

1 Power System Model |

2.2. CONVENTIONAL

PID CONTROLLER

Ziegler and Nichols have suggested a

method to calculate the controller gain values. The values of critical gain ![]() and the critical

period

and the critical

period ![]() are used for calculation

of the gain values, as shown in Table 1, using the gain equations given below:

are used for calculation

of the gain values, as shown in Table 1, using the gain equations given below:

![]() Equation 17

Equation 17

![]() Equation 18

Equation 18

![]() . Equation 19

. Equation 19

Table 1

|

Table 1 PID

Controller Parameters |

|||||

|

Plant |

|

|

|

|

|

|

Thermal |

0.286 |

12.289 |

0.177 |

0.028 |

0.264 |

|

Nuclear |

0.181 |

19.137 |

0.109 |

0.012 |

0.261 |

|

Hydro |

0.112 |

16.885 |

0.067 |

0.008 |

0.142 |

2.3. SUGENO FUZZY LOGIC CONTROLLER

Takagi-Sugeno-Kang

proposed an approach for developing fuzzy rules from the given input-output

data. Sugeno fuzzy inference system (a knowledge or

rule-based) is used in this non-linear power systems with uncertainty. In this

controller, the inputs are fuzzifying and then applying the fuzzy operator, but

membership functions in the output are either constant or linear. A rule in the

Sugeno model consists of two inputs, error (p) and

derivative of error (q), and an output (r). This rule is given by

IF p is X and q is Y, THEN r is r = f

(p, q)

where X and Y are the linguistic

variables, and f (p, q) is a polynomial function of p and q.

The inference system is a zero-order

model if f (p, q) is a constant and is a first-order model if f (p, q) is a

linear function of p and q. Because each rule has a crisp output, the overall

output is obtained via the weighted average defuzzification method. The

defuzzification is done through the weighted average method. Table 2 shows the fuzzy associative memory (FAM) table to form

forty-nine rules with triangular membership functions, and the output function

is taken as a constant to obtain the fuzzy inference system (fis) file.

Table 2

|

Table 2 FAM Table |

||||||||

|

Rule

Bases |

Derivative

Error (DACE) |

|||||||

|

NB |

NM |

NS |

Z |

PS |

PM |

PB |

||

|

Error |

NB |

PB |

PB |

PM |

PM |

PS |

PS |

Z |

|

(ACE) |

NM |

PB |

PM |

PM |

PM |

PS |

Z |

Z |

|

NS |

PB |

PM |

PM |

PM |

Z |

NS |

NS |

|

|

Z |

PB |

PM |

PM |

Z |

NS |

NM |

NB |

|

|

PS |

PM |

PM |

NS |

NS |

NM |

NB |

NB |

|

|

PM |

PM |

PS |

NS |

NM |

NB |

NM |

NB |

|

|

PB |

NS |

NS |

NM |

NM |

NM |

NM |

NB |

|

2.4. ANFIS

CONTROLLER

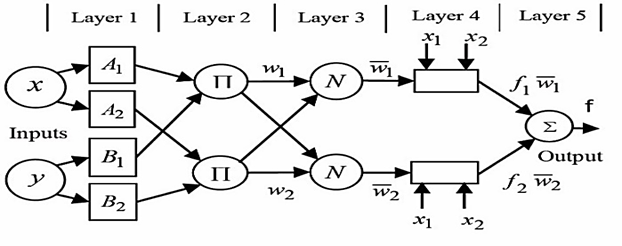

It combines neural network and fuzzy logic algorithms to obtain a Sugeno-type fis file. It is designed using a hybrid learning rule with backpropagation. The gradient descent optimization method is used to obtain the training data. The two rules and five layers of the ANFIS structure are shown in Figure 2.

R1: IF x is ![]() &

y is

&

y is ![]() , THEN

, THEN ![]()

R2: IF x is ![]() &

y is

&

y is ![]() ,

THEN

,

THEN ![]()

where ![]() ,

, ![]() and

and ![]() ,

,![]() are the linguistic

variables.

are the linguistic

variables. ![]() ,

, ![]() ,

,![]() and

and![]() ,

, ![]() ,

,![]() are the consequent parameters.

are the consequent parameters.

The training data set is collected from Sugeno fuzzy logic controller outputs. This data is

uploaded in the anfis editor to generate the fis file. The grid partitioning technique with 5x5 gbell and linear type membership functions are used. The

generated fis file is used in training the data set

with hybrid and backpropagation optimization techniques for 20 epochs. The

process of training and testing the data is repeated until the error reduces to

![]() .

Generate the fis file with the gbell function for all four areas separately.

This file is used in the ANFIS controller to simulate the power system and get

the desired output.

.

Generate the fis file with the gbell function for all four areas separately.

This file is used in the ANFIS controller to simulate the power system and get

the desired output.

Figure 2

Figure 2

|

Figure

2 ANFIS

Architecture |

3. RESULTS AND DISCUSSIONS

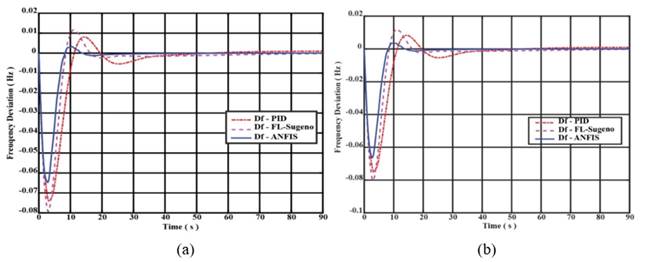

The system parameters are given in

Appendix A at a nominal frequency ![]() of 50 Hz. The simulation

of a developed power system model is performed for each type of controller. The

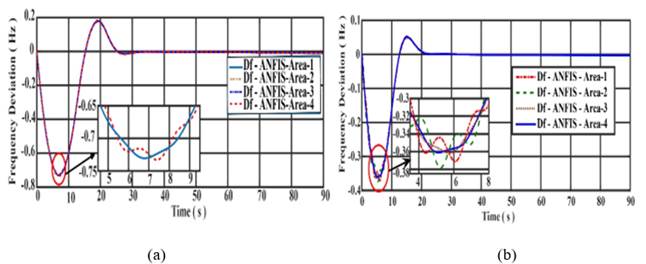

simulation is carried out using Matlab. Consider the case with a 1% step load

increase simultaneously in all the areas (A1 to A4); the frequency deviation

of 50 Hz. The simulation

of a developed power system model is performed for each type of controller. The

simulation is carried out using Matlab. Consider the case with a 1% step load

increase simultaneously in all the areas (A1 to A4); the frequency deviation ![]() with three types of

controllers is shown in Figure 3 and Figure 4. As the load increases, the speed decreases, and hence frequency

decreases.

with three types of

controllers is shown in Figure 3 and Figure 4. As the load increases, the speed decreases, and hence frequency

decreases.

Further, the speed increases due to the primary control action by the speed governor and the secondary control action by the ANFIS controller. This results in zero ACE deviation. It is evident from the simulation results that the proposed controller reduced the steady state error and improved the transient responses in terms of undershoot, settling time, and the smaller value of ITAE.

Figure 3

|

Figure

3 |

Figure 4

|

Figure

4 |

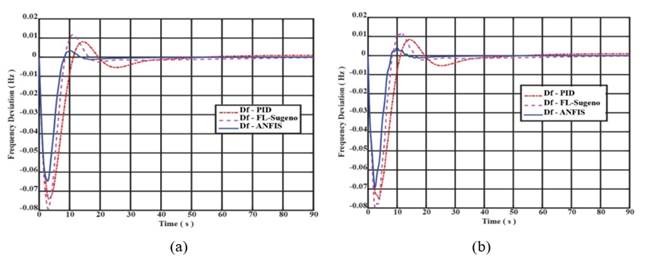

The step change in load ![]() from 1% to 4% in each area

is considered. The ITAE values and the step response characteristics,

undershoot

from 1% to 4% in each area

is considered. The ITAE values and the step response characteristics,

undershoot ![]() , and settling time

, and settling time ![]() , are measured in each case. Table 3 shows the comparative study of characteristics and error values

for each case. Figure 5 (a) shows the

, are measured in each case. Table 3 shows the comparative study of characteristics and error values

for each case. Figure 5 (a) shows the ![]() with ANFIS controller

under 4% step load change (equal load). The transient specifications are the

settling time of 27.9823 sec (min) and undershoot of - 0.7374 Hz (min) with an

ITAE value of 1.541, which are measured. These specifications are acceptable

and smaller compared to conventional controllers. Figure 5 (b) shows the

with ANFIS controller

under 4% step load change (equal load). The transient specifications are the

settling time of 27.9823 sec (min) and undershoot of - 0.7374 Hz (min) with an

ITAE value of 1.541, which are measured. These specifications are acceptable

and smaller compared to conventional controllers. Figure 5 (b) shows the ![]() with ANFIS controller

under

with ANFIS controller

under ![]() in each area. Its dynamic

response is good with a very minimum steady.

in each area. Its dynamic

response is good with a very minimum steady.

Table 3

|

Table 3 Settling Time, Maximum

Undershoot and ITAE of

Frequency Deviation |

||||||||||

|

Load |

Controllers |

Settling Time (sec) |

Maximum Undershoot (Hz) |

ITAE |

||||||

|

|

|

A1 |

A2 |

A3 |

A4 |

A1 |

A2 |

A3 |

A4 |

|

|

+1 % |

PID |

37.4276 |

37.0483 |

37.4279 |

36.7415 |

-0.0741 |

-0.0752 |

-0.0741 |

-0.0749 |

0.1128 |

|

|

Fuzzy |

35.3831 |

24.1459 |

35.3825 |

23.7027 |

-0.0793 |

-0.0802 |

-0.0793 |

-0.0798 |

0.0903 |

|

|

ANFIS |

12.5448 |

12.6491 |

12.5449 |

12.2472 |

-0.0647 |

-0.0664 |

-0.0647 |

-0.0692 |

0.0255 |

|

+2 % |

PID |

31.4877 |

31.4790 |

31.4883 |

31.3404 |

-0.2334 |

-0.2341 |

-0.2334 |

-0.2358 |

0.3229 |

|

|

Fuzzy |

18.4069 |

18.3627 |

18.4069 |

18.3300 |

-0.2346 |

-0.2352 |

-0.2346 |

-0.2378 |

0.2314 |

|

|

ANFIS |

16.2255 |

16.2110 |

16.2255 |

15.8983 |

-0.2289 |

0.2289 |

0.2289 |

-0.2333 |

0.3635 |

|

+3 % |

PID |

25.8549 |

25.7815 |

25.8546 |

25.8021 |

-0.4649 |

-0.4649 |

-0.4649 |

-0.4714 |

0.8842 |

|

|

Fuzzy |

21.8765 |

21.8081 |

21.8767 |

21.7396 |

-0.4647 |

-0.4648 |

-0.4647 |

-0.4713 |

0.7378 |

|

|

ANFIS |

20.8092 |

20.6850 |

20.8092 |

20.7816 |

-0.4606 |

-0.4606 |

-0.4606 |

-0.4682 |

0.8374 |

|

+4 % |

PID |

48.2282 |

48.7783 |

48.2355 |

47.6003 |

-0.7440 |

-0.7440 |

-0.7440 |

-0.7503 |

1.9070 |

|

|

Fuzzy |

39.8828 |

57.6070 |

39.8753 |

39.8705 |

-0.7424 |

-0.7424 |

-0.7424 |

-0.7497 |

2.0750 |

|

|

ANFIS |

28.0254 |

29.2096 |

27.9823 |

28.9171 |

-0.7374 |

-0.7374 |

-0.7374 |

-0.7426 |

1.5410 |

Figure 5

|

Figure

5 |

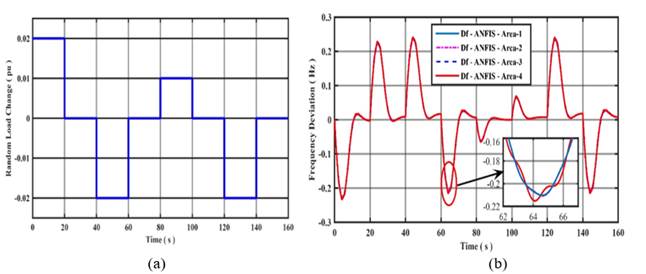

The robustness of the ANFIS controller with a random load

curve, as shown in Figure 6 (a), is assessed for all four areas, and the frequency

deviations (![]() are shown in Figure 6 (b). It is observed that the ANFIS controller exactly tracks

the load curve as the load increases the system frequency decreases. It matches

the generation with load demand and losses at a constant frequency. For the

case with an equal change in load, frequency deviation occurs in the respective

areas which are less than the threshold value.

are shown in Figure 6 (b). It is observed that the ANFIS controller exactly tracks

the load curve as the load increases the system frequency decreases. It matches

the generation with load demand and losses at a constant frequency. For the

case with an equal change in load, frequency deviation occurs in the respective

areas which are less than the threshold value.

For the system with the proposed ANFIS controller, the

values of ![]() and

and ![]() at a 3% change in load, these values are -

0.4606 Hz (min) and 20.6850 sec (min), respectively. For a 2% change in load,

these values are - 0.2289 Hz (min) and 15.8983 sec (min), respectively, and at

a 1% change in load, these values are further reduced to - 0.0647 Hz (min) and

12.2472 sec (min), respectively. Thus, the obtained time response

characteristics are smaller compared to the values given in the literature by

Deepesh Sharma (2020) and Feng Liu (2017). Hence, the proposed ANFIS controller

is more effectively tuned with GRCs than PID and FL controllers.

at a 3% change in load, these values are -

0.4606 Hz (min) and 20.6850 sec (min), respectively. For a 2% change in load,

these values are - 0.2289 Hz (min) and 15.8983 sec (min), respectively, and at

a 1% change in load, these values are further reduced to - 0.0647 Hz (min) and

12.2472 sec (min), respectively. Thus, the obtained time response

characteristics are smaller compared to the values given in the literature by

Deepesh Sharma (2020) and Feng Liu (2017). Hence, the proposed ANFIS controller

is more effectively tuned with GRCs than PID and FL controllers.

Figure 6

|

Figure

6 (a) Random Load Curve and (b) |

4. CONCLUSIONS

This research article is presented to assess the effectiveness of an ANFIS controller in four control areas with different sources connected through tie-lines. Transient analysis is carried out, considering the tandem compound TF models of steam turbines and the nonlinearity of GRC under equal and unequal loads. The Z-N method is employed to tune the controller gains and minimize the value of ITAE. The simulation of the model for an equal change in load shows that the proposed ANFIS controller provides a very significant improvement. Its dynamic step responses have smaller values of specifications compared to conventional and fuzzy logic controllers. The proposed controller is robust and quickly adaptable to nonlinearity in the system. Also, this work shows that the ANFIS controller performs very effectively even under random demand changes, and thus the power system stability is achieved.

5. NOMENCLATURE

![]() :

Power system rated capacity,

:

Power system rated capacity, ![]() :

Nominal load,

:

Nominal load, ![]() :

Tie-line power,

:

Tie-line power, ![]() :

Load damping constant,

:

Load damping constant, ![]() :

Frequency bias factor,

:

Frequency bias factor, ![]() :

Inertia constant,

:

Inertia constant, ![]() :

Governor speed regulation,

:

Governor speed regulation, ![]() : Nominal frequency,

: Nominal frequency, ![]() :

Frequency deviation,

:

Frequency deviation, ![]() :

Power angle,

:

Power angle, ![]() :

Synchronizing torque co-efficient,

:

Synchronizing torque co-efficient, ![]() :

Power system gain,

:

Power system gain, ![]() :

Power system, Governor, Turbine, Reheater, Crossover time constants,

respectively,

:

Power system, Governor, Turbine, Reheater, Crossover time constants,

respectively, ![]() ,

,

![]() ,

,![]() ,

,

![]() : Fraction

of turbine power at HP, LP, IP and VHP sections respectively,

: Fraction

of turbine power at HP, LP, IP and VHP sections respectively, ![]() :

Turbine water starting time constant,

:

Turbine water starting time constant, ![]() :

Hydro governor reset time constant,

:

Hydro governor reset time constant, ![]() :

Hydro governor temporary droop,

:

Hydro governor temporary droop, ![]() :

Hydro governor permanent droop.

:

Hydro governor permanent droop.

6. SYSTEM PARAMETERS

![]() =

2000MW,

=

2000MW, ![]() =

1000MW,

=

1000MW, ![]() =

200MW,

=

200MW, ![]() = 2.5Hz/pu MW,

= 2.5Hz/pu MW,

![]() = 30deg.,

= 30deg., ![]() =

0.0866.

=

0.0866.

For thermal plant: ![]() = 0.01pu MW/Hz,

= 0.01pu MW/Hz, ![]() = 0.41pu MW/Hz,

= 0.41pu MW/Hz, ![]() = 5MJ/MVA,

= 5MJ/MVA, ![]() =

0.2sec,

=

0.2sec,

![]() =

0.3sec,

=

0.3sec, ![]() =

7sec,

=

7sec, ![]() =

0.4sec,

=

0.4sec, ![]() =

0.3,

=

0.3,

![]() =

0.4,

=

0.4, ![]() = 0.3,

= 0.3, ![]() =

100Hz/pu MW,

=

100Hz/pu MW,

![]() =

20sec. GRC =

=

20sec. GRC = ![]()

For nuclear plant: ![]() = 0.01pu MW/Hz,

= 0.01pu MW/Hz, ![]() = 0.41pu MW/Hz,

= 0.41pu MW/Hz, ![]() = 5MJ/MVA,

= 5MJ/MVA, ![]() =

0.2sec,

=

0.2sec,

![]() =

0.3sec,

=

0.3sec, ![]() =

7sec,

=

7sec, ![]() =

0.4sec,

=

0.4sec, ![]() =

0.22,

=

0.22,

![]() =

0.56,

=

0.56, ![]() = 0.22,

= 0.22, ![]() =

100Hz/pu MW,

=

100Hz/pu MW, ![]() =

20sec.

=

20sec.

For hydro plant: ![]() = 0.015pu MW/Hz,

= 0.015pu MW/Hz, ![]() = 0.415pu MW/Hz,

= 0.415pu MW/Hz, ![]() = 4MJ/MVA,

= 4MJ/MVA, ![]() =

10sec,

=

10sec,

![]() =

1sec,

=

1sec, ![]() =

5sec,

=

5sec, ![]() =

0.2875Hz/pu MW,

=

0.2875Hz/pu MW, ![]() =

0.05Hz/pu MW,

=

0.05Hz/pu MW, ![]() =

66.6667Hz/pu MW,

=

66.6667Hz/pu MW,

![]() =

10.6667s. GRC =

=

10.6667s. GRC = ![]() and

and ![]() .

.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

The authors are grateful to the Principal of Bapuji Institute of Engineering and Technology, Davanagere, Karnataka, for their support, encouragement, and facilities in carrying out this research.

REFERENCES

Bhaskar,M. K., Pal, N.S. and

Yadav, V. K. (2018). A Comparative Performance Analysis of Automatic

Generation Control of Multi-Area Power System Using PID, Fuzzy And ANFIS

Controllers, IEEE International Conference on Power Electronics, Intelligent

Control, and Energy Systems, Delhi, India, 132-137, 2018. https://doi.org/10.1109/ICPEICES.2018.8897477.

Chandrakala, K.R.M.V. and Balamurugan.S. (2018). Adaptive Neuro-Fuzzy Scheduled Load Frequency Controller for Multi-Source Multi Area System Interconnected Via Parallel AC-DC Links, International Journal on Electrical Engineering and Informatics, 10(3), 479-490. https://doi.org/10.15676/ijeei.2018.10.3.5.

IEEE : Power and Energy Society. (2013). Technical Report on Dynamic Models

for Turbine-Governors in Power System Studies, Power System Dynamic Performance Committee, PES-TR1.

Khezri, R., Golshannavaz, S., Shokoohi, S. and Bevrani, H. (2016). Fuzzy Logic Based Fine-Tuning Approach for Robust Load Frequency Control in a Multi-Area Power System, Electric Power Components and Systems, Taylor and Francis Group, 44(18), 2073–2083. https://doi.org/10.1080/15325008.2016.1210265.

Liu, F., Wang, H., Shi, Q., Wang, H., Zhang, M. and Zhao, H. (2017). Comparison of an ANFIS and Fuzzy PID Control Model for Performance in a Two-Axis Inertial Stabilized Platform, IEEE Access, 5, 12951-12962. https://doi.org/10.1109/ACCESS.2017.2723541.

Kundur. P. (1994). Power System Stability and Control, Vol. 2, New York, McGraw-Hill.

Prakash, S. and Sinha, S. K. (2017). Automatic Load

Frequency Control of Six Areas Hybrid Multi-Generation Power Systems using

Neuro-Fuzzy Intelligent Controller, IETE Journal of Research, 64(4), 471-481. https://doi.org/10.1080/03772063.2017.1361869.

Sahin, E. (2020). Design of an Optimized Fractional High Order Differential Feedback Controller for Load Frequency Control of a Multi-Area Multi-Source Power System with Nonlinearity, IEEE Access, 8, 12327-12342. https://doi.org/10.1109/ACCESS.2020.2966261.

Shaker, H. K., Zoghby, H.E., Bahgat, M. E. and

Abdel-Ghany, A. M.(2019). Advanced Control Techniques for an

Interconnected Multi Area Power System for Load Frequency Control,

International Conf. on Middle East Power Systems, Tanta University, Egypt,

710-715. https://doi.org/10.1109/MEPCON47431.2019.9008158.

Sharma,

D. (2020). Automatic Generation Control of Multi-Source Interconnected

Power System using Adaptive Neuro-Fuzzy Inference System, International Journal

of Engineering, Science and Technology, 12(3), 66-80. https://doi.org/10.4314/ijest.v12i3.7.

Sharma, D., Pandey, K., Kushwaha ,V. and Sehrawat, S. (2016).

Load Frequency Control of Four-Area Hydro-Thermal Interconnected Power System

through ANFIS Based Hybrid Neuro-Fuzzy Approach, International Innovative

Applications of Computational Intelligence on Power, Energy and Controls with

their Impact on Humanity, 144-149. https://doi.org/10.1109/CIPECH.2016.7918755.

Zhang,Y., Liu, X. and Qu, B. (2017). Distributed Model Predictive Load Frequency Control of Multi-Area Power System with DFIGs, IEEE/CAA Journal of Automatica Sinica, 4(1), 125-135. https://doi.org/10.1109/JAS.2017.7510346.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2022. All Rights Reserved.