|

|

|

|

ECONOMIC DESIGN OF PIPE-NOZZLE DISCHARGE LINES DELIVERING FREE JETS

Mohamed M. M. Amin 1![]() , Medhat M. H. ElZahar 2

, Medhat M. H. ElZahar 2![]()

![]()

1 Professor

of Hydraulics, Civil Engineering Department, Faculty of Engineering, Port Said

University, Port Said, Egypt

2 Associate Professor of Sanitary and Environmental Engineering, Department

of Civil Engineering, Faculty of Engineering, Port Said University, Port

Said, Egypt

|

|

ABSTRACT |

||

|

The present

study focuses on finding an economic design of nozzles used in water

discharge lines. An analytical solution is reached for computing the economic

pipe-nozzle diameter ratio achieving the minimum pipe cost using the

derivative method. The derived equation shows that at a particular

pipe-nozzle diameter ratio, the pipe cost CP is minimum. However,

this is evident from the worked illustrative example. On a comparison basis

between this equation and the conventional one, the derived equation shows a

satisfactory reduction in the pipe cost, which may reach 56.7%. It is of

great interest to recognize that, by increasing the relative distance to 400,

a reduction in pipe cost of 231 % associated with an increase in the power of

the jet by 41.5 %, are verified. Also, the derived equation achieves a

reduction in pipe cost ranging from 34 to 39.7 % depending on the frictional

effects in the approach pipe. The study reflects the reliability of the

derived equation in computing the economic pipe-nozzle diameter ratio used in

discharge lines delivering free jets. However, there are many engineering

applications of water jet nozzles used in; water filters, flotation tanks,

sedimentation tanks, water storage tanks, trickling filters, and other units

of water and wastewater systems. |

|||

|

Received 17 August 2022 Accepted 23 September 2022 Published 08 October 2022 Corresponding Author Medhat M.

H. ElZahar, medhat.alzahar@eng.psu.edu.eg

DOI 10.29121/ijetmr.v9.i10.2022.1232 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download, reuse,

re-print, modify, distribute, and/or copy their contribution. The work must

be properly attributed to its author.

|

|||

|

Keywords: Discharge Lines,

Economic Considerations, Pipe-Nozzle Diameter Ratio, Free Jets, Pipe Cost

Function |

|||

1. INTRODUCTION

The pipe-nozzle discharge lines are known for a wide range of applications in practice, they are generally used to have a high-velocity water jet that can be used for firefighting, mining, and power developments (the impulse turbines) Featherstone and El-Jumaily (1983), Streeter and Wylie (1985), Sharp (1985). Most of the studies are based on hydraulic considerations, and in this study, an analytical solution has been reached using a derivative method associated with the economic considerations and comparison requirements Simon (1987), Somaida (1994), Somaida et al. (2011), Somaida et al. (2012). Little is found in the literature concerning the present problem. Most of the previous studies are directed toward having the maximum power of the jet delivered from the nozzle. However, the present study is based on economic considerations satisfying the choosing of the pipe-nozzle diameter ratio leading to the minimum cost of the discharge line. This will be presented within the scope here. However, an analytical solution is derived to solve the problem with comparison requirements John et. al. (2011), Mazzoleni (1994), Joseph et al. (2010), Somaida et al. (2013).

In practice, pipe nozzles are widely used in many water and wastewater engineering applications, such as irrigation systems, water supply, and wastewater system arrangements Wright et al. (2003), Poeck (2008). Common applications of nozzles in water and wastewater treatment systems are as follows: Koirala et al. (2021), BETE for Nozzle Performance Engineering (2022):

· Evaporative disposal, such as disposal of excess water/chemical solution through evaporation, usually over a large pond.

· Foam control, Spray nozzles to break up foam that can cause tank overflow, poor drainage, or other problems.

· Mixing and blending tank contents, homogenizing sediment off the tank bottom to aid in transportation and filtration, sweeping solids across the bottom of the tank, and preventing thermal stratification.

· Filter nozzles, which can be installed in both open and closed filters, to ensure maximum efficiency with minimum head losses Wright (2003), BETE for Nozzle Performance Engineering (2022).

· Also, water jet lines and nozzles are used for sewer cleaning Medan et al. (2017).

There are analytical methods for the development of comprehensive costing dealing with the economic sizes of any pipeline Sharp (1985). This can be applied to the present problem, where the pipeline ends with a nozzle acting as a gravity main and should have the optimum diameter ratio Somaida et al. (1994), Somaida et al. (2011), Somaida et al. (2012), Somaida et al. (2013). Poeck et al. (2008), studied a performance evaluation of various nozzle designs for waterjet scaling in underground excavations. Design and optimization of discharge pipelines delivering free jets are of high concern in industry based on economic considerations Renjie (2020), Schwartzentruber et al. (2016).

2. MATERIALS AND METHODS

2.1. Minor nozzle loss

It is usually considered that for pipe of length longer than 1000 diameter (L/D>1000), the error incurred by neglecting minor losses is less than that inherent in selecting the value of friction factor F Joseph et al. (2010). In the case of an approach pipe ending with a nozzle, Figure 1, which has a known assumed loss coefficient, the head loss as associated with the high issuing velocity head and is therefore not as minor loss. But, in the present study, it is suggested that the minor loss of the nozzle may be expressed in terms of the equivalent length of approach pipe (Le), that has the same head loss for the same discharge delivered from the nozzle De Cock (2017), Radkevich et al. (2021), or

![]() Equation 1

Equation 1

Where F = friction factor of approach pipe, Le = equivalent length of pipe, VP = velocity of flow in approach pipe, D = diameter of approach pipe, g = acceleration of gravity, K = loss coefficient of minor loss due to nozzle, VJ = absolute velocity of the jet, and d = diameter of nozzle opening (diameter of jet).

Note that from continuity equation,

![]() Equation 2

Equation 2

Therefore, the total length of the pipe will be:

![]() Equation 3

Equation 3

However, the solution will be built around the friction factor of the approach pipe, rather than minor loss of the nozzle.

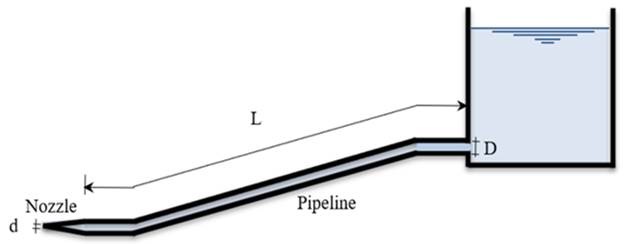

Figure 1

|

Figure

1 Pipe-Nozzle Discharge Line |

2.2. Pipe-nozzle discharge line cost

The pipe cost CP is given by, Sharp (1985)

![]() Equation 4

Equation 4

Where, a = pipe cost function and x = pipe cost exponent.

However, considering the pipe cost CP of the pipe-nozzle discharge line, the equation of total pipe cost will be given by:

Where, K = loss coefficient of the nozzle, which is known

by ![]() ,

where Cv = coefficient of velocity in the nozzle.

,

where Cv = coefficient of velocity in the nozzle.

2.3. Derivative optimum for D/d ratio

In order to obtain the optimum D/d ratio, use the derivative method except that the cost gradient will be relative to the diameter of the approach pipe D, because the pipe now forms a major part of the scheme. However, for minimum pipe cost, differentiate Equation 5, with respect to D, and equate to zero, with the following assumptions:

1) Constant diameter of nozzle opening d.

2) Turbulent flow conditions and Reynold’s number ranges from 105 to 106, where the loss coefficient of the nozzle is relatively constant, without serious error, Joseph et al. (2010).

3) Variable coefficient of friction.

Differentiate Equation 5 with respect to D and equate to zero, then:

Put Equation 6 in the following form:

![]()

The partial in the L.H.S. of Equation 7,

![]() can be written in the form:

can be written in the form: ![]() or

or

![]() ,

However, Equation 7,

can take the form:

,

However, Equation 7,

can take the form:

The form ![]() can be evaluated from Von Karman formula for

F:

can be evaluated from Von Karman formula for

F: ![]() .

.

Introducing the diameter ratio, B ![]() ,

or

,

or ![]() ,

؞

,

؞

![]()

Or ![]() .

The term

.

The term ![]() in this equation is constant.

in this equation is constant.

Differentiate F in this equation with respect to d,

؞ ![]() ,

or

,

or ![]()

Substitute by ![]() in Equation 8,

in Equation 8,

Put the diameter ratio ![]() ,

in Equation 9

and rearrange for B, then:

,

in Equation 9

and rearrange for B, then:

Where K is the minor loss coefficient of the nozzle = ![]() ,

since

,

since ![]() ,

Streeter

and Wylie (1985) and C is the flow

coefficient of the nozzle. However, the diameter ratio D/d depends on friction

factor F of approach pipe, loss coefficient of nozzle K, relative distance L/D,

and pipe cost exponent x. Equation 10

can be solved by trial and error.

,

Streeter

and Wylie (1985) and C is the flow

coefficient of the nozzle. However, the diameter ratio D/d depends on friction

factor F of approach pipe, loss coefficient of nozzle K, relative distance L/D,

and pipe cost exponent x. Equation 10

can be solved by trial and error.

2.4. Illustrative example

In the present illustrative example, the following data

are given L = 20, D = 0.1m, relative distance L/D = 200, relative roughness e/D

= 0.02 (F = 0.05). In view of the pipe cost exponent x, it was taken 0.45 by Featherstone

and El-Jumaily (1983) and 1.03 by Somaida et al. (2012), However, it is taken

2.5 in the present study. The values of C at different D/d are evaluated using

the following equation, which is evaluated by linear regression analysis of the

data concerning the flow ratio C and the diameter ratio ![]() being interpreted from Streeter and Wylie (1985)(“Fig. 8.16”, P. 467).

being interpreted from Streeter and Wylie (1985)(“Fig. 8.16”, P. 467).

![]() Equation 11

Equation 11

The results obtained by solving Equation 10 by trial and error as shown in Table 1.

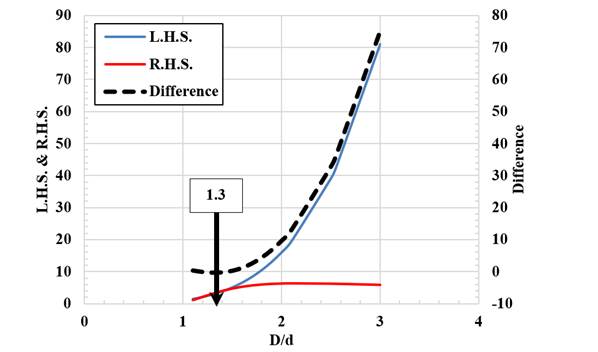

Graphical solution of Equation 10 based on minimum pipe cost is shown in Figure 2. This figure and Table 2 show that, the solution of Equation 10 is satisfying at average value of D/d = 1.3.

Table 1

|

Table 1 Solving Equation 10 by Trial

and Error at Different D/d for the Illustrative Example (L/D = 200 and

F=0.05) |

||||||

|

B (D/d) |

C |

Cv |

K |

L.H.S. |

R.H.S. |

Difference |

|

1.1 |

0.8991 |

0.5062 |

2.9027 |

1.464 |

1.0260 |

0.4381 |

|

1.2 |

0.8919 |

0.6418 |

1.4279 |

2.074 |

2.0856 |

-0.0120 |

|

1.3 |

0.8854 |

0.7137 |

0.9630 |

2.856 |

3.0926 |

-0.2365 |

|

1.4 |

0.8794 |

0.7563 |

0.7483 |

3.842 |

3.9798 |

-0.1382 |

|

1.5 |

0.8738 |

0.7827 |

0.6321 |

5.063 |

4.7112 |

0.3513 |

|

1.6 |

0.8686 |

0.7996 |

0.5640 |

6.554 |

5.2800 |

1.2736 |

|

1.7 |

0.8638 |

0.8104 |

0.5226 |

8.352 |

5.6993 |

2.6528 |

|

1.8 |

0.8593 |

0.8173 |

0.4970 |

10.498 |

5.9919 |

4.5057 |

|

1.9 |

0.8550 |

0.8215 |

0.4817 |

13.032 |

6.1831 |

6.8490 |

|

2 |

0.8510 |

0.8239 |

0.4730 |

16 |

6.2963 |

9.7037 |

|

2.1 |

0.8472 |

0.8251 |

0.4689 |

19.448 |

6.3511 |

13.0970 |

|

2.5 |

0.8337 |

0.8229 |

0.4766 |

39.063 |

6.2485 |

32.8140 |

|

2.55 |

0.8322 |

0.8223 |

0.4791 |

42.283 |

6.2168 |

36.0657 |

|

3 |

0.8198 |

0.8147 |

0.5065 |

81 |

5.8798 |

75.1202 |

2.5. Rigidity of the derived equation

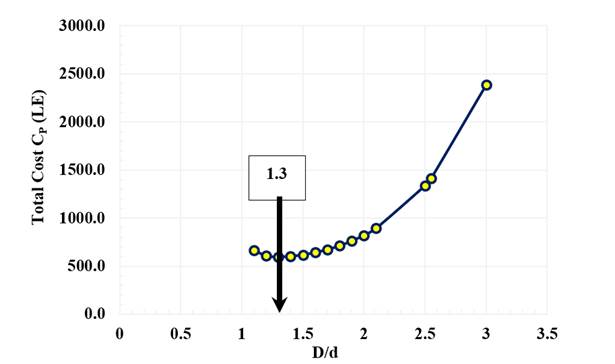

For this purpose, the total pipe cost CP is computed at different pipe-nozzle diameter ratios D/d. The results are shown in Table 2, which is also used to plot CP versus D/d as shown in Figure 3. Investigation of both table and figure show the following: (A) Diameter ratios D/d above 1.6 give high pipe costs, while smaller D/d give low total costs. (B) The minimum pipe cost lies at D/d = 1.4, which is also reached by the solution of the derived Equation 10. This assures the rigidity of the derived solution for computing pipe-nozzle diameter ratio D/d.

Figure 2

|

Figure

2 Graphical Solution of Equation 10 Based on

Minimum Pipe Cost for the Illustrative Example |

Table 2

|

Table 2 Results for Total Pipe

Cost CP Versus Diameter Ratio D/d for the Illustrative Example |

||||

|

D/d |

C |

Cv |

K |

CP (LE) |

|

1.1 |

0.8991 |

0.5062 |

2.9027 |

666.9 |

|

1.2 |

0.8919 |

0.6418 |

1.4279 |

606.6 |

|

1.3 |

0.8854 |

0.7137 |

0.9630 |

596.7 |

|

1.4 |

0.8794 |

0.7563 |

0.7483 |

602.6 |

|

1.5 |

0.8738 |

0.7827 |

0.6321 |

617.8 |

|

1.6 |

0.8686 |

0.7996 |

0.5640 |

641.0 |

|

1.7 |

0.8638 |

0.8104 |

0.5226 |

672.3 |

|

1.8 |

0.8593 |

0.8173 |

0.4970 |

712.2 |

|

1.9 |

0.8550 |

0.8215 |

0.4817 |

761.8 |

|

2 |

0.8510 |

0.8239 |

0.4730 |

822.2 |

|

2.1 |

0.8472 |

0.8251 |

0.4689 |

894.8 |

|

2.5 |

0.8337 |

0.8229 |

0.4766 |

1339.4 |

|

2.55 |

0.8322 |

0.8223 |

0.4791 |

1416.0 |

|

3 |

0.8198 |

0.8147 |

0.5065 |

2388.1 |

3. RESULTS AND DISCUSSIONS

3.1. Evaluation of minimum cost

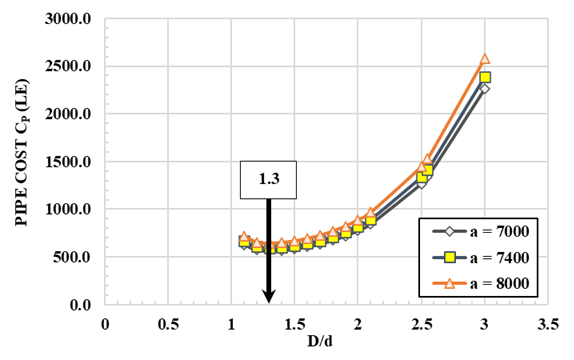

3.1.1. Variation of CP versus D/d (variable pipe cost coefficient a)

The data given within the illustrative example are x = 2.5, F = 0.05, and L/D = 200, while the pipe cost factor a is taken 7000, 7400, and 8000, Table 3. The corresponding plots of CP versus D/d at various pipe cost factor (a) are shown in Figure 4. Investigation of these plots shows the following:

1) The plots exhibit similar trends.

2) The increase of diameter ratio D/d leads to increase of CP, and the rate of increase being at higher D/d (1.8-3), Figure 4.

3) At a fixed value of D/d, CP increases with increase of the pipe cost coefficient a.

4) All the plots indicate that the minimum pipe cost CP takes place at a unique diameter ratio of 1.3, Table 3.

Figure 3

|

Figure

3 Plot of Total Pipe Cost CP

Versus Diameter Ratio D/d for the Illustrative Example |

Figure 4

|

Figure

4 Plots of CP

Versus D/d for the Illustrative Example at Various Pipe Cost Exponent A |

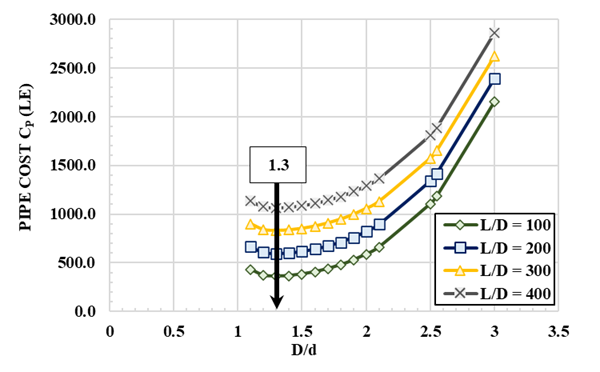

3.1.2. Variation of CP versus D/d (variable relative distance L/D)

The data given within the illustrative example are:

x = 2.5, F = 0.05, a = 7400, and L/D = (100, 200, 300, and 400), Table 4. The corresponding plots are shown in Figure 5. Investigation of these plots leads to the following: (A) The plots exhibit similar trends. (B) The pipe cost CP increases with increase of D/d, the rate of increase being higher at larger D/d ratios (1.8-3.0), Figure 5. (C) In all the plots, it is found that, at a particular value of D/d, CP increases with increase of e/D, which is logical. (D) In all the plots, the minimum CP is at D/d = 1.3, Table 4.

Table 3

|

Table 3 Results of Total Pipe

Cost CP Versus Diameter Ratio D/D For Various Unit Pipe Exponent A |

||||||

|

D/d |

C |

Cv |

K |

CP (LE) |

||

|

a |

||||||

|

7000 |

7400 |

8000 |

||||

|

1.1 |

2.9027 |

0.5062 |

2.9027 |

630.9 |

666.9 |

721.0 |

|

1.2 |

0.8919 |

0.6418 |

1.4279 |

573.8 |

606.6 |

655.8 |

|

1.3 |

0.8854 |

0.7137 |

0.9630 |

564.5 |

596.7 |

645.1 |

|

1.4 |

0.8794 |

0.7563 |

0.7483 |

570.0 |

602.6 |

651.4 |

|

1.5 |

0.8738 |

0.7827 |

0.6321 |

584.4 |

617.8 |

667.9 |

|

1.6 |

0.8686 |

0.7996 |

0.5640 |

606.4 |

641.0 |

693.0 |

|

1.7 |

0.8638 |

0.8104 |

0.5226 |

635.9 |

672.3 |

726.8 |

|

1.8 |

0.8593 |

0.8173 |

0.4970 |

673.7 |

712.2 |

770.0 |

|

1.9 |

0.8550 |

0.8215 |

0.4817 |

720.6 |

761.8 |

823.6 |

|

2 |

0.8510 |

0.8239 |

0.4730 |

777.8 |

822.2 |

888.9 |

|

2.1 |

0.8472 |

0.8251 |

0.4689 |

846.5 |

894.8 |

967.4 |

|

2.5 |

0.8337 |

0.8229 |

0.4766 |

1267.0 |

1339.4 |

1448.0 |

|

2.55 |

0.8322 |

0.8223 |

0.4791 |

1339.5 |

1416.0 |

1530.8 |

|

3 |

0.8198 |

0.8147 |

0.5065 |

2259.1 |

2388.1 |

2581.8 |

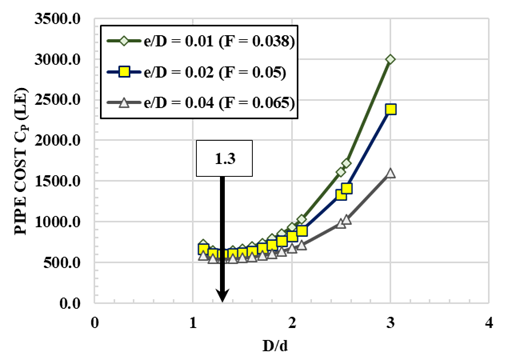

3.1.3. Variation of CP versus D/d (variable e/D and F)

The data given within the illustrative example are x = 2.5, a = 7400, and L/D = 200, The variable is e/D (0.01, 0.02, 0.04) which corresponds to F (0.038, 0.05, 0.065), Table 5. The corresponding plots are shown in Figure 6. Investigation of these plots lead to the following conclusions:

(A) All the plots exhibit similar trends. (B) In each plot, CP increases with increase of D/d being from (1.8 to 3.0). (C) In the plots, at a particular value of D/d, CP decreases with increase of relative roughness e/D, the rate of decrease being larger for higher D/d (2.0 to 3.0). (D) In all the plots, the minimum cost CP occurs at D/d = 1.3. This is attributed to that, in each case solving of Equation 10 for the minimum cost diameter ratio D/d, the left-hand side of the equation converges to D/d = 1.3.

Table 4

|

Table 4 Results of Total Pipe

Cost CP Versus Diameter Ratio D/D for Various Relative Length |

|||||||

|

D/d |

C |

Cv |

K |

CP (LE) |

|||

|

L/D |

|||||||

|

100 |

200 |

300 |

400 |

||||

|

1.1 |

0.8991 |

0.5062 |

2.9027 |

432.9 |

666.9 |

900.9 |

1134.9 |

|

1.2 |

0.8919 |

0.6418 |

1.4279 |

372.6 |

606.6 |

840.6 |

1074.6 |

|

1.3 |

0.8854 |

0.7137 |

0.9630 |

362.7 |

596.7 |

830.8 |

1064.8 |

|

1.4 |

0.8794 |

0.7563 |

0.7483 |

368.6 |

602.6 |

836.6 |

1070.6 |

|

1.5 |

0.8738 |

0.7827 |

0.6321 |

383.8 |

617.8 |

851.8 |

1085.8 |

|

1.6 |

0.8686 |

0.7996 |

0.5640 |

407.0 |

641.0 |

875.0 |

1109.0 |

|

1.7 |

0.8638 |

0.8104 |

0.5226 |

438.3 |

672.3 |

906.3 |

1140.3 |

|

1.8 |

0.8593 |

0.8173 |

0.4970 |

478.2 |

712.2 |

946.2 |

1180.2 |

|

1.9 |

0.8550 |

0.8215 |

0.4817 |

527.8 |

761.8 |

995.8 |

1229.8 |

|

2 |

0.8510 |

0.8239 |

0.4730 |

588.2 |

822.2 |

1056.2 |

1290.2 |

|

2.1 |

0.8472 |

0.8251 |

0.4689 |

660.8 |

894.8 |

1128.8 |

1362.9 |

|

2.5 |

0.8337 |

0.8229 |

0.4766 |

1105.4 |

1339.4 |

1573.4 |

1807.4 |

|

2.55 |

0.8322 |

0.8223 |

0.4791 |

1182.0 |

1416.0 |

1650.0 |

1884.0 |

|

3 |

0.8198 |

0.8147 |

0.5065 |

2154.1 |

2388.1 |

2622.2 |

2856.2 |

Figure 5

|

Figure

5 Plots of CP Versus

D/D for the Illustrative Example at Various Relative Distance L/D |

Figure 6

|

Figure

6 Plots of CP versus D/d for the Illustrative

Example at Various Relative Roughness e/D |

3.1.4. Variation of CP versus D/d (variable e/D and F)

The data given within the illustrative example are x = 2.5, a = 7400, and L/D = 200, The variable is e/D (0.01, 0.02, 0.04) which corresponds to F (0.038, 0.05, 0.065), Table 5. The corresponding plots are shown in Figure 6. Investigation of these plots lead to the following conclusions:

(A) All the plots exhibit similar trends. (B) In each plot, CP increases with increase of D/d being from (1.8 to 3.0). (C) In the plots, at a particular value of D/d, CP decreases with increase of relative roughness e/D, the rate of decrease being larger for higher D/d (2.0 to 3.0). (D) In all the plots, the minimum cost CP occurs at D/d = 1.3. This is attributed to that, in each case solving of Equation 10 for the minimum cost diameter ratio D/d, the left-hand side of the equation converges to D/d = 1.3.

Table 5

|

Table 5 Results of CP

versus D/d for various L/D (100, 200, 300, and 400) and e/D (0.01, 0.02, and

0.04) |

||||||

|

D/d |

C |

Cv |

K |

CP (LE) |

||

|

e/D |

||||||

|

0.01 |

0.02 |

0.04 |

||||

|

1.1 |

0.8991 |

0.5062 |

2.9027 |

729.7 |

666.9 |

585.0 |

|

1.2 |

0.8919 |

0.6418 |

1.4279 |

650.4 |

606.6 |

549.5 |

|

1.3 |

0.8854 |

0.7137 |

0.9630 |

637.4 |

596.7 |

543.7 |

|

1.4 |

0.8794 |

0.7563 |

0.7483 |

645.0 |

602.6 |

547.2 |

|

1.5 |

0.8738 |

0.7827 |

0.6321 |

665.1 |

617.8 |

556.1 |

|

1.6 |

0.8686 |

0.7996 |

0.5640 |

695.7 |

641.0 |

569.8 |

|

1.7 |

0.8638 |

0.8104 |

0.5226 |

736.8 |

672.3 |

588.2 |

|

1.8 |

0.8593 |

0.8173 |

0.4970 |

789.3 |

712.2 |

611.7 |

|

1.9 |

0.8550 |

0.8215 |

0.4817 |

854.6 |

761.8 |

640.8 |

|

2 |

0.8510 |

0.8239 |

0.4730 |

934.1 |

822.2 |

676.4 |

|

2.1 |

0.8472 |

0.8251 |

0.4689 |

1029.6 |

894.8 |

719.1 |

|

2.5 |

0.8337 |

0.8229 |

0.4766 |

1614.5 |

1339.4 |

980.6 |

|

2.55 |

0.8322 |

0.8223 |

0.4791 |

1715.4 |

1416.0 |

1025.7 |

|

3 |

0.8198 |

0.8147 |

0.5065 |

2994.5 |

2388.1 |

1597.5 |

Table 6

|

Table 6 Results of D/d, PJ and CP

using Equation 10 and

the Conventional Formula (F=0.05 and L/D (100-400) for the

illustrated example) |

||||||

|

L/D |

Eq. (10) |

Conventional Formula |

||||

|

D/d |

PJ |

CP |

D/d |

PJ |

CP |

|

|

(KW) |

(LE) |

(KW) |

(LE) |

|||

|

100 |

1.3 |

0.4 |

303.8 |

1.78 |

1.16 |

336.1 |

|

200 |

1.3 |

0.79 |

607.5 |

2.115 |

1.1 |

951.9 |

|

300 |

1.3 |

1.124 |

911.3 |

2.34 |

1.02 |

1846.7 |

|

400 |

1.3 |

1.575 |

926.6 |

2.5 |

0.92 |

3070.4 |

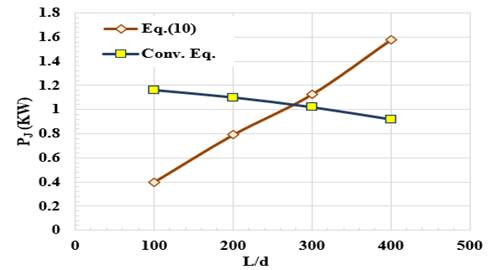

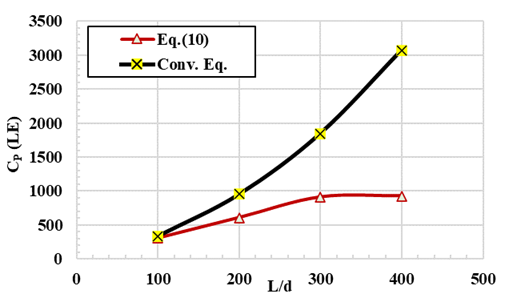

3.2. Comparison between minimum cost and conventional formulae computing D/d

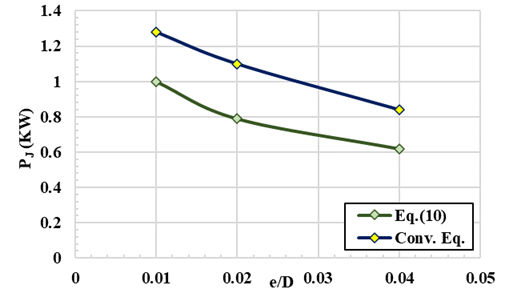

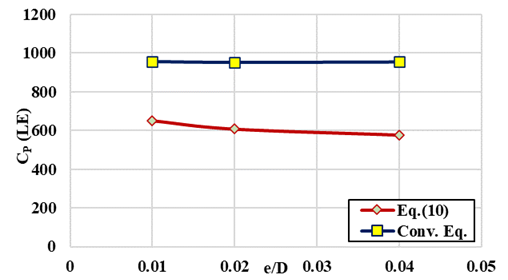

For this purpose, Table 6 is constructed showing the important parameters to be compared using both formulae, where CP is calculated at F = 0.05, and L/D as taken (100, 200, 300, and 400).

Investigation of Table 6 indicates that: (A) The derived Equation 10 shows a unique value for D/d = 1.3 which satisfies the minimum CP, while in the conventional formula, D/d increases with L/D. (B) Eq. (10), shows that PJ increases with increase of L/D and vice versa by the conventional formula, Figure 7. According to Equation 10, the increase in the jet power ranges from 14.5 to 55.6 percent by increase of L/D, while in the conventional formula shows a decrease in jet power by 26 percent. (C) With respect to the pipe cost CP, Table 6 and Figure 6 and Figure 8, in both equations, CP increases with increase of e/D, but Equation 10 shows marked reduction in CP with increase of L/D. Also, Equation 10 achieves lower values of CP compared with the conventional formula for example, at L/D = 100, the conventional formula, shows an increase of CP of 10.6 percent and 231.4 percent at L/D = 400, indicating that Equation 10, is more reliable than the conventional one.

Table 7

|

Table 7 Results of D/d, PJ

and CP using Equation 10 and the Conventional Formula (L/D=200, for the Illustrative Example) |

||||||

|

e/D |

Eq. (10) |

Conventional Formula |

||||

|

D/d |

PJ |

CP |

D/d |

PJ |

CP |

|

|

(KW) |

(LE) |

(KW) |

(LE) |

|||

|

0.01 |

1.4 |

1 |

651.7 |

1.98 |

1.28 |

957.8 |

|

0.02 |

1.4 |

0.79 |

607.5 |

2.115 |

1.1 |

951.9 |

|

0.04 |

1.4 |

0.62 |

575.5 |

2.252 |

0.84 |

954.8 |

Figure 7

|

Figure

7 Results of

D/d Versus PJ using Equation 10 and Conventional

Formula for L/D=200 |

On the other hand, Table 7 is constructed for D/d, PJ, and CP using Equation 10 and the conventional formula at L/D = 200, e/D (0.01, 0.02, and 0.04) or F (0.038, 0.05, and 0.065) respectively. Table 7 and the plots in Figure 9, indicate the following: (A) The two plots of PJ versus e/D, have the same trend, indicating that PJ decreases with increase of e/D, due to the frictional effects in the approach pipe, but the conventional equation gives higher values of PJ, Figure 9, this is attributed to the nature of this equation. (B) With respect to the plots of CP and e/D both equations, have similar trends with a marked reduction of CP indicated by Equation 10, Figure 10 Plots of CP Versus e/D for the Illustrative Example at L/D=200. However, the use of Equation 10 shows, reduction in CP ranges from 34 at e/D=0.01 and 39.7 % at e/D=0.04, which indicates the validity of Equation 10 and that the conventional formula is approximate.

Figure 8

|

Figure

8 Results of D/d Versus CP

using Equation 10 and Conventional Formula for L/D=200 |

Figure 9

|

Figure

9 Plots of PJ Versus e/D for the Illustrative

Example at L/D=200 |

Figure 10

|

Figure

10 Plots of CP Versus e/D for the Illustrative

Example at L/D=200 |

Finally, it may be stated that, the results obtained for computing the minimum cost of pipe-nozzle diameter ratio in discharge lines delivering free jets, by the derived Equation 10, indicate the validity of the equation in estimating the economic pipe-nozzle diameter ratio, D/d, the corresponding power of the jet PJ, and the minimum cost of the discharge line CP.

4. CONCLUSIONS and RECOMMENDATIONS

The following conclusions can be reached as follows:

1) Equation 10, derived for computing the economic nozzle-pipe diameter ratio D/d in discharge lines delivering free jets, is applicable over practical ranges of relative distance L/D and relative roughness e/D under rough, turbulent flow conditions (in approach pipe). For the time being, L/D ranges from 50 to 500, e/D ranges from 0.01 to 0.05, and Rn from 105 to 106.

2) In the given illustrated example, Equation 10derived for D/d ratio, is solved by trial and error, and shows that the economic diameter ratio is close to 1.3, where the total pipe cost has a minimum value. Also, the results of CP, show that the derived equation holds good for D/d ratios from 1.1 to 3.0, Table 5, and could be applied without the need for a computer program.

3) Investigation of Equation 10, shows that the economic diameter ratio D/d depends on; the relative distance L/D, the coefficient of friction F in the approach pipe, the minor loss coefficient of the nozzle K, and the pipe cost exponent x.

4) On comparison basis between Equation 10 and the conventional formula, at (F = 0.05, L/D = 200), the first shows that at the economic ratio D/d = 1.3, the pipe cost CP = 607.5LE and the power of the jet, PJ = 0.97KW, while in the conventional equation, D/d = 2.115, CP = 951.9LE and the power of the jet, PJ = 1.1KW. However, the derived Equation 10, realizes a reduction in CP by 56.7% and in PJ by 39.2%. But the reduction in CP is wanted as it is the main purpose of the present study.

5) On the other hand, at F = 0.05 and by increase of L/D to 400, still economic D/d = 1.4, PJ = 1.575KW, and CP = 9266LE by the use of the derived Eq. (10). While the conventional formula shows that D/d = 2.5, PJ = 0.92KW, and CP = 30704LE, Table 6. However, at F = 0.05 and L/D = 400, it is found that Equation 10 attains a reduction in CP by 231% with an increase in PJ by 41.6% compared with the conventional formula.

6) Considering the friction in the approach pipe, it has the effect of decreasing PJ when computed by the conventional formula. While use of Equation 10, shows reduction in CP ranging from 34 to 39.7 %, indicating the validity of the derived equation.

7) It may be stated that, the evaluation study of Equation 10 reflects the rigidity and reliability of this equation in computing the economic pipe-nozzle diameter ratio D/d in discharge lines delivering free jets and for the time being, good results are obtained at F = 0.05 and L/D = 400, higher PJ and lower CP.

5. NOMENCLATURE

F = Coefficient of friction in the approach pipe,

D = Mean diameter of approach pipe,

Le = Equivalent length of approach pipe,

g = Gravitational acceleration,

Vp = Mean velocity of water in the approach pipe,

D/d = Pipe-nozzle diameter ratio

VJ = Absolute velocity of the jet at the nozzle opening,

d = diameter of the nozzle opening.

K = Minor loss coefficient of the nozzle,

L = Length of approach pipe,

CP = Pipe Cost,

Cv = Coefficient of velocity of the nozzle,

a = pipe cost function,

x = Pipe cost exponent,

C = Flow coefficient of the nozzle,

L/D = Relative distance,

PJ = power of the jet,

e = Roughness height in approach pipe,

e/D = Relative roughness of pipe,

PJ = Power of the jet.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

BETE for Nozzle Performance Engineering (2022). Spray Nozzles For The Waste Management Industry.

De Cock, N. (2017). Design of a Hydraulic Nozzle with a Narrow Droplet Size Distribution. Phd Dissertation, Université De Liège, Liège, Belgium.

Featherstone, R. E., and El-Jumaily, K. K. (1983). Optimal Diameter Selection for Pipe Networks. Journal of Hydraulic Engineering, 109(2), 221-234, Computer-Aided Design, 15(5), 300. https://doi.org/10.1061/(ASCE)0733-9429(1983)109:2(221).

Joseph B. Franzini, E., and Finnemore, J. (2010). Fluid Mechanics with Engineering Applications. Mcgraw-Hill College, MA, USA, 10th International Edition.

Koirala, R., Ve, Q. L., Zhu, B., Inthavong, K., and Date, A. (2021). A Review on Process and Practices in Operation and Design Modification of Ejectors. Fluids, 6(11), 409. https://doi.org/10.3390/fluids6110409.

Mazzoleni, A. P. (1994). Design of High-Pressure Waterjet Nozzles. Alabama Univ., Research Reports : 1994 NASA (ASEE Summer Faculty Fellowship Program).

Medan, N., Banica, M., and Ravai-Nagy, S. (2017). Full Factorial DOE to Determine and Optimize the Equation of Impact Forces Produced by Water Jet Used in Sewer Cleaning. MATEC Web of Conferences, 137, 07003. https://doi.org/10.1051/matecconf/201713707003.

Poeck, E. C. (2008). Performance Evaluation of Various Nozzle Designs for Waterjet Scaling in Underground Excavations, Phd Dissertation, Colorado School of Mines.

Radkevich, M., Abdukodirova, M., Shipilova, K., and Abdullaev, B. (2021). Determination of the Optimal Parameters of the Jet Aeration. IOP Conference Series: Earth and Environmental Science, 939(1), 012029.

Renjie, L., Xiaochen, L., Jin-Shi, L., and Zhang, X. (2020). Design and Simulation of Curved Nozzle for Removing the Fish Scale by the Water Jet. U.P.B. Science Bulletin, Series D, 82(1).

Schwartzentruber, J., Narayanan, C., Papini, M., and Liu, H. T. (2016). Optimized Abrasive Waterjet Nozzle Design Using Genetic Algorithms. The 23rd International Conference on Water Jetting, Seattle, USA.

Sharp, B. B. (1985). Economics of Pumping and the Utilization Factor. Journal of Hydraulic Engineering, 111(11), 1386–1395. https://doi.org/10.1061/(ASCE)0733-9429(1985)111:11(1386).

Simon, A.L.SS. (1987). Hydraulics. John Wiley and Sons Ltd, 3rd Edition.

Somaida M., El-Zahar M., and Sharaan M. (2012). The Use of Computer Simulation and Analytical Solutions for Optimal Design of Pipe Networks Supplied from a Pumped-Groundwater Source. Port Said Engineering Research Journal, 16(1), 106-117.

Somaida, M. M. (1994). Optimal Design of Pipe-Nozzle Lines Discharging Free Jets. Port Said Engineering Research Journal, 6(1).

Somaida, M. M., El-Zahar, M. M., Hamed, Y. A., and Sharaan, M. S. (2013). Optimizing Pumping Rate in Pipe Networks Supplied by Groundwater Sources. KSCE Journal of Civil Engineering, 17(5), 1179-1187. https://doi.org/10.1007/s12205-013-0116-4.

Somaida, M., Elzahar, M., and Sharaan, M. (2011). A Suggestion of Optimization Process for Water Pipe Networks Design. International Conference on Environment and Bio-Science IPCBEE, 21, 68-73.

Streeter, V. L., Wylie, E. B. (1985). Fluid Mechanics. Mcgraw-Hill Education, 8th Edition.

Swaffield, J., Jack, L., Douglas, J. F. and John Gasiorek. (2011). Fluid Mechanics, Pearson Canada, 6th Edition.

Wright, D., Wolgamott, J., and Zink, G. (2003). Water Jet Nozzle Material Types. WJTA American Waterjet Conference, 17-19.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2022. All Rights Reserved.