|

|

|

|

VALIDATION OF Σ−YLIQ ATOMIZATION MODEL IN PRESSURE SWIRL ATOMIZER

Sherry K. Amedorme

1![]() , NR.N. Roselina 2

, NR.N. Roselina 2![]()

1 Department

of Mechanical and Automotive Technology, Akenten

Appiah-Menka University of Skills Training and

Entrepreneurial Development, Kumasi-Ghana

2 Faculty

of Mechanical Engineering, Universiti Teknologi MARA, 40450 Shah Alam

Selangor Malaysia

|

|

ABSTRACT |

||

|

In many

combustion and agricultural applications atomizers are used to increase the

surface area of the liquid to ensure high rates of mixing and improve

evaporation. The most common, simple, and reliable atomizer is the pressure

swirl atomizer. This atomizer is said to have quality and effective atomization

compared to others and induces swirling motion to the liquid and gives a

hollow cone spray with air core as it emerges from the exit orifice. To

enhance the understanding and prediction of the atomizing characteristics

various atomization models are used and need to be investigated

experimentally. This paper presents a validation of the Σ−Yliq atomization model of two-phase flow in a pressure

swirl atomizer using commercial CFD star-cd code and laser-diffraction based

drop measurements. To obtain the best results for the droplet mean diameter

between the prediction and the experiment in terms of turbulence different

k-e models were evaluated. The results show that the computational

predictions of Sauter Mean Diameter (SMD) for the model have a good agreement

with most of the experimental measurements in the radial positions when

standard k-ɛ turbulence was used. However, more divergence was observed

between the predictions and the experimental measurements when the RNG and

Realizable k-ɛ turbulence models were used in the predictions. It was also observed that the model has

good agreement with the mean droplet measurements on the spray centreline and radial axis with a percentage error of

less than five percent. |

|||

|

Received 05 August 2022 Accepted 04 September 2022 Published 17 September 2022 Corresponding Author Sherry K.

Amedorme, smedorme@yahoo.com DOI10.29121/ijetmr.v9.i9.2022.1182 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2022 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Pressure

Atomizer Swirl, Atomization Model, Sauter Mean Diameter (SMD), Validation |

|||

1. INTRODUCTION

Pressure swirl atomizer also known as simplex

atomizers are of different types ranging from plain orifice to dual orifice

atomizers. The fundamental principle of this atomizer is that liquid is induced

in the tangential ports and the combination of the swirling and the translation

motion of the liquid result in the liquid leaving the exit orifice as a hollow

cone sheet with the formation of air core in the centre. The hollow cone sheet

disintegrates into ligaments and then forms droplets Lefebvre et al. (2017), Rashad et al. (2016), Cui et al. (2017). Liu et al. (2019) and Malý et al. (2018) studied the

motion of liquid in the pressure swirl atomizer and indicate that the flow

mechanism inside and outside the atomizer is complex and not well understood.

Amongst several causes, factors such as the operating condition, design, and

size of the atomizer tested, complex atomization process, as well as

limitations of drop measurement instrument and techniques are very key

considerations. In terms of design, the pressure atomizer has inlet ports,

swirl chamber, and an outlet orifice.

The tangential inlet ports are of several channels and designs and

introduce liquid fuel to the swirl chamber which imparts swirl energy to the

liquid fuel and also contains air-core vortex. In this

chamber, a portion of the swirl motion of the liquid is converted to axial

velocity for the liquid to emerge as a hollow cone spray. The outlet orifice

has contraction or convergence and contains holes for the liquid to be

discharged Dafsari et al. (2017), Liu et

al. (2017).

In these parts of the pressure swirl atomizer, the

pressure exerted on the wall by the liquid, the tangential and the axial

components of the velocity, and air-core characteristics are some of the

important parameters analysed. These parameters significantly affect the

discharge coefficient at the exit orifice, mean droplet sizes and distribution,

spray cone angle, velocity distributions, and the liquid film thickness of the

spray emanating from the atomizer. Several researchers including, Hu et al. (2019) and Wu et al. (2020), Shin et al. (2019), Ortman and Lefebvre (1985), and Zhang et al. (2017) and Dafsari et al. (2019) studied the

influence of injection pressure on spray cone angle. The results obtained show

that within a given range of injection pressures, the equivalent spray angle is

inversely related to the change in pressure. Ortman

and Lefebvre also show that starting from atmospheric pressure, the spray cone

angle first widens and then contracts with increases in the liquid pressure.

The most common research on a pressure-swirl atomizer is the influence of

pressure on the mean drop size. Several researchers including Lefebvre and Wang (1987), Belhadef et al. (2012), and Emekwuru and Watkins (2010) did extensive work

in this regard. They show that the mean drop sizes emanating from the

pressure-swirl atomizer decrease with increasing pressure. It is also observed

that within the swirl chamber the pressure is constant but decreases sharply in

both the convergence zone and the outlet orifice. The liquid velocity which has

axial, tangential, and longitudinal components also depend mainly on the

injection pressure and affect the degree of atomization Khani et al. (2020). The internal

characteristics and the nozzle dimensions are not the only factors that govern

atomization performance. Other factors relating to the liquid and ambient gas

properties also affect greatly the mean droplet size and distribution. The

instabilities and break-up of the liquid sheet are promoted by the gas density

due to aerodynamic interaction but prevented by the liquid properties such as

surface tension and viscosity. The ambient gas varies widely in pressure and

temperature and influences strongly the mean droplet

sizes and the spray angle. it is indicated that the ambient gas increases with

decreasing spray angle until a maximum spray value is reached which does not

affect the spray angle. Due to the higher inertia of the liquid phase, liquid density

also alters the performance of the atomizer and the atomization characteristics,

and it has been shown that its effect on the mean droplet size is quite minimal

Lefebvre and McDonell (2017). In many studies,

the liquid viscosity is the most important liquid property analysed in this

atomizer. As indicated by Lefebvre although its influence on atomization is not

that significant as the surface tension, however, its relevance is because it

does not only influence the mean drop size and distribution but flow rate and

the spray formation as well. A key

effect of increase in liquid viscosity is its reduction influence on the

Reynolds number and the prevention of liquid sheet natural instability and

break up. The overall effect is that it delays the disintegration of the liquid

jet or sheet and increases the droplet sizes in the spray.

However, in a pressure swirl atomizer, a slight

rise in the viscosity maximizes the flow rate which is achieved by increasing

the liquid film thickness in the discharge orifice which in turn makes the

effective flow area to be raised. But beyond the optimal liquid viscosity, this

trend changes and the flow rate reduce with increase in liquid. The liquid flow

rate does not only depend on the liquid properties but also on the geometrical

sizes and the pressure difference across the atomizer Wimmer and Brenn

(2012). Beheshti et al. (2007) assessed Ʃ

−Y model in an air-assisted atomizer and predicted the effects of liquid

properties and injection regimes on the atomization quality It was shown that

the model predictions and experimental data have a good agreement for a wide

range of variations of density and surface tension of the liquid as well as the

injection regimes for liquid and gas jet exit velocities. They noted however

that the model is limited in the fact that it only attempts to resolve the

Sauter mean diameter (SMD) and as such is unable to resolve effects caused by a

wide distribution of droplet size in polydispersed

sprays such as ballistic drop spreading. They concluded that this is acceptable

in the current application because existing experimental data for gaseous and

aerosol jets show a lower spreading rate for an increasingly heavy central jet

suggesting that variable density effects are more dominant than ballistic

spreading Gharbi et al. (1996), Trask (2010), Beheshti et al. (2007).

In modelling two-phase flow in pressure swirl

atomizers using computational fluid dynamics (CFD) two approaches are commonly

used. The Eulerian approach where the spray is treated as a continuum within

the computational flow domain and the Lagrangian

technique tracked the droplets in the flow domain. Lin et al. (2009) and Xiong et al. (2009) carried out a study

on non-swirling effervescent atomization spray using a combination of a

Eulerian k-ɛ turbulence model to capture the droplets and gas-phase

interaction in the secondary break-up and use the Lagrangian

approach to model the disperse droplet phase. In this study, the droplet

velocity is calculated in a far-field using a single-phase approach developed

for high-density variation. In using the Eulerian method to solve two-phase

problems the state equations of each phase are solved and the interaction

between the two phases must be accounted for. This requires complex modelling

and a high number of equations as each fluid is transported Bishop (1975), Drew (1983), Mirjalili et al. (2017). This work focuses

on the entirely one-fluid Eulerian model which potentially brings the advantage

to compute only the transport of one single fluid with a high-density variation

Belhadef et al. (2012). This novel and

general mathematical model developed and presented by Vallet et al. (2001) for an entirely

Eulerian model called the Ʃ-Y atomization model has the potential for all

the basic necessary capabilities. It describes atomization from the first

principle. However, its validation in pressure swirl atomizer is insufficient

and has not been demonstrated well enough at the time being and therefore needs

further research and improvement.

2. MATERIALS AND METHODS

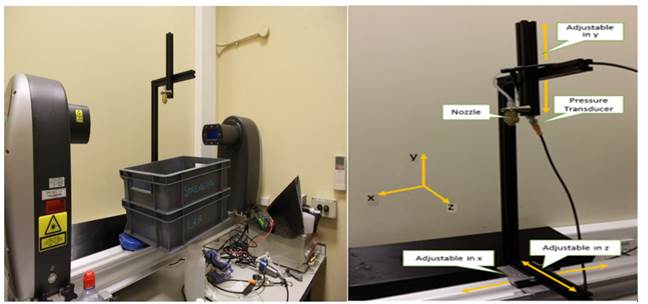

The experiment was performed using the Malvern Spraytec drop measuring instrument as shown in Figure 1. Liquid water in 0.4l container was pumped to

the mainline with the aid of a 240V power source. The speed of the pump was

controlled by a 300W triple source which enables the supply voltage to be

varied. In measuring the mean droplet sizes at the various flow rate, the

voltage supplied to the pump was varied since the flow rate could not be

measured directly. The voltages of 0.5, 1, 1.5, 2 and 2.5 were used. The pressure transducer was used to measure

pressure drop across the apparatus and the pressure in the system is detected

by a pressure sensor which converts it to an analogue signal to be read by the

digital multimeter which then changes back to

pressure. The circuit set up for the pressure measurement apparatus was in the

range of 4-20mA containing a 500Ω resistor. The designed atomizer was

clamped to a vertical stand to allow easy changing, and the liquid was sprayed

downwards into the laser beam. The stand was built to accommodate variations in

all directions above the laser beam. To prevent the deflection and splashback

of the liquid absorbent tissue paper was put in the container.

Figure 1

|

Figure

1 Experimental Setup |

The PFS 1392B1 atomizer used

was produced by PNR Ltd which is a nozzle manufacturing company based in the

UK. The specifications of the atomizer are inlet and exit diameters of 3.7 and

3.5mm respectively with a rated spray angle of 70 degrees and 3.90 per minute

as flow rate at 3.0 bar gauge pressure as shown in Table 1. Liquid water was used for the experiment

with density, viscosity property values as 1000 kg/m3, 0.001kg/ms, and 0.072 kg/s2 respectively Crowley et al. (1990) Emekwuru and Watkins (2010). The

parameters of the Malvern instrument are shown in Table 2.

Table 1

|

Table 1 Atomizer Specification |

||||

|

Atomizer length L (mm) |

Height H (mm) |

Atomizer Exit diameter (mm) |

Liquid Inlet diameter (mm) |

|

|

Stainless steel |

34 |

24 |

3.5 |

3.7 |

Table 2

|

Table 2 Spraytec Specification Malvern-Instruments

(2007) |

|

|

Parameter |

Value |

|

Laser power |

Max 4mW He-Ne Laser, |

|

Data acquisition rate |

10kHz- Rapid mode 1Hz-Continuous mode |

|

Measurement Time |

30 seconds - Rapid mode 60 minutes -Continuous mode |

|

Lens Focal Length |

300mm and 750mm |

|

System Power |

100/240v, 50/60 Hz |

|

Mean drop size range |

0.1-2500 um |

3. RESULTS AND DISCUSSIONS

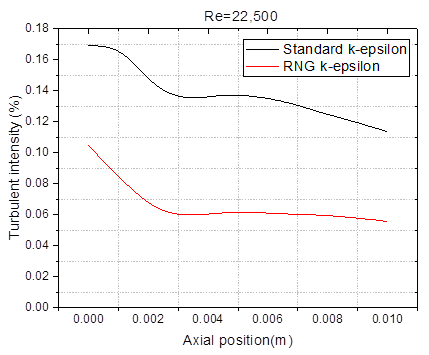

Figure 2 shows the graph of turbulent intensity

decays along the axial position by comparing the standard k-epsilon and RNG

k-epsilon turbulence models. It can be observed that the standard k-epsilon

model predicted a higher decay in the average turbulent intensity as compared

to RNG k-epsilon. In comparing the two ![]() turbulence models, the inlet turbulent

intensity was kept constant. In theory, turbulence is affected by swirl in the

mean flow. Since the RNG model accounts for this rotational motion appropriately

by modifying the turbulent viscosity, larger decay could be counted for and

therefore the turbulence in the flow gets uniformly distributed in the swirl

chamber and the computational domain as compared to the standard

turbulence models, the inlet turbulent

intensity was kept constant. In theory, turbulence is affected by swirl in the

mean flow. Since the RNG model accounts for this rotational motion appropriately

by modifying the turbulent viscosity, larger decay could be counted for and

therefore the turbulence in the flow gets uniformly distributed in the swirl

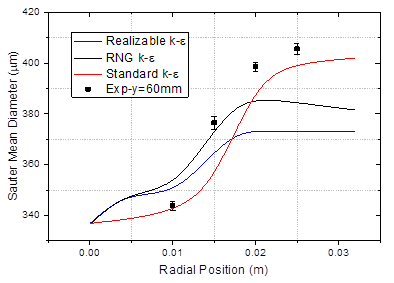

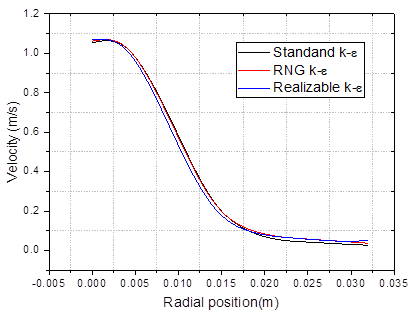

chamber and the computational domain as compared to the standard ![]() model. In Figure 3, it can be seen that

10% of turbulent intensity is nearer to the experimental data points and the

standard k-epsilon model utilize in this atomization is the best because it

tends to produce the smallest SMD and the best match and configurations with

the experimental results when compared to the RNG and Realizable K-epsilon

turbulence models (Figure 4). It is observed

that the turbulent intensity is greater in the periphery of the spray

than the

center spread of the nozzle, and this conforms to the

observation made by Yoon

et al. (2011). This is due to the

droplet which decreases momentum in the outside spray making an enormous impact

by the inflow of surrounding air. Towards the downstream of the spray, the

turbulent intensity gets smaller because the momentum of relative velocity is sharply

reduced and there are less actions of air current for droplet which is related

with the highly small amount of air brought by its surroundings. However, there

were no significant changes in the droplet velocity when the three turbulent

models were compared as shown in Figure 5.

model. In Figure 3, it can be seen that

10% of turbulent intensity is nearer to the experimental data points and the

standard k-epsilon model utilize in this atomization is the best because it

tends to produce the smallest SMD and the best match and configurations with

the experimental results when compared to the RNG and Realizable K-epsilon

turbulence models (Figure 4). It is observed

that the turbulent intensity is greater in the periphery of the spray

than the

center spread of the nozzle, and this conforms to the

observation made by Yoon

et al. (2011). This is due to the

droplet which decreases momentum in the outside spray making an enormous impact

by the inflow of surrounding air. Towards the downstream of the spray, the

turbulent intensity gets smaller because the momentum of relative velocity is sharply

reduced and there are less actions of air current for droplet which is related

with the highly small amount of air brought by its surroundings. However, there

were no significant changes in the droplet velocity when the three turbulent

models were compared as shown in Figure 5.

Figure 2

|

Figure 2 Turbulent Intensity Decays Along the Axial Position by Comparing the Standard and RNG K-Ε Turbulence Models |

Figure 3

|

Figure

3 Effect of Turbulent Intensity on SMD |

|

Figure 4 Effect of Turbulence Models on SMD at y=60mm |

Figure 5

|

Figure 5 Influence of

Turbulence Models on the Mean Liquid Velocity, Modelling |

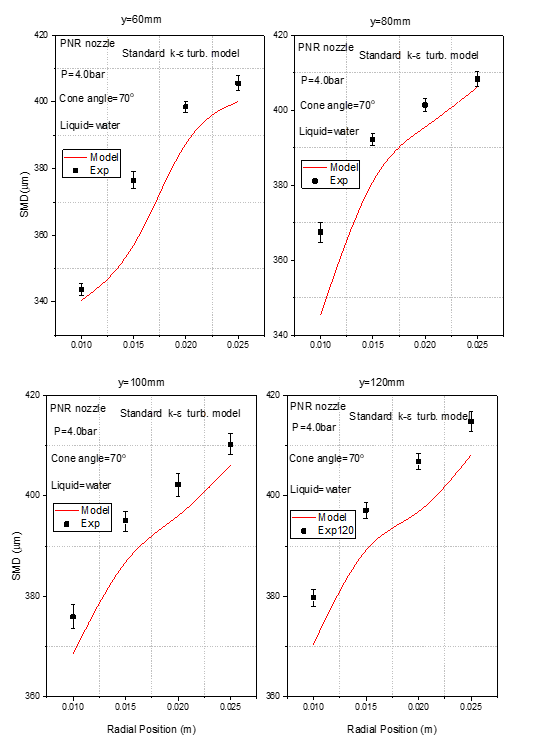

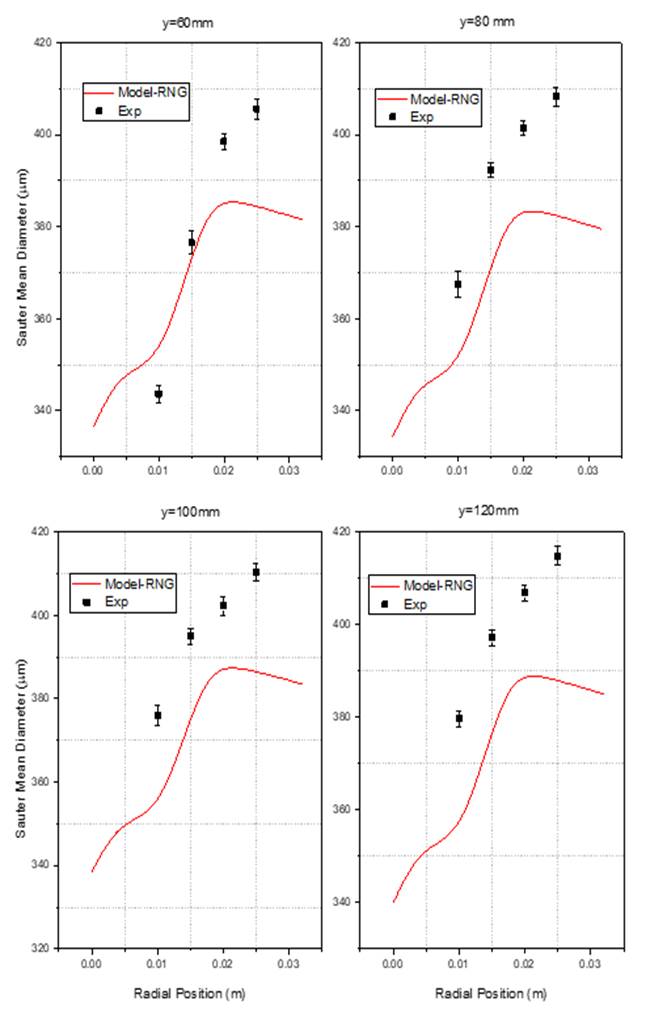

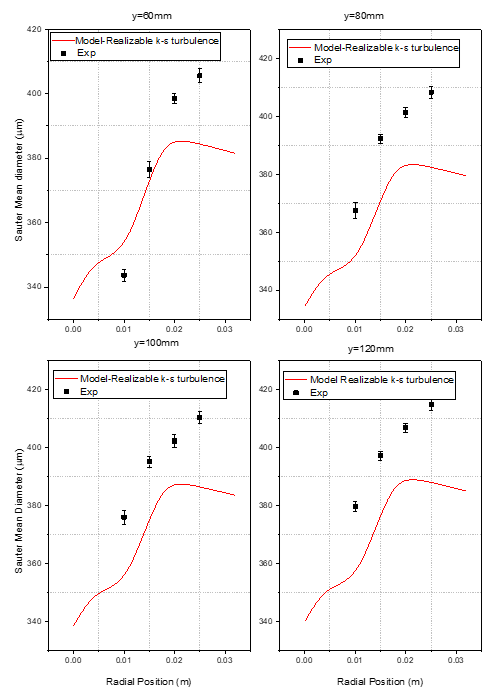

Figure 6 shows the

comparison of the model with measurements for droplet Sauter Mean Diameter

(SMD) at y=60, 80, 100 and 120 mm. The agreement between the model and

experimental radial profiles at 60 mm downstream of the nozzle is good. The

trend shows that the Sauter mean diameter SMD increases with increasing radial

distances which is qualitatively correct, but the rate of change is small with

the mean diameter of the large droplets found on the periphery of the spray

under-predicted and the small mean drop size at the vicinity of the spray

centreline perfectly predicted. At the axial position of 80 mm from the exit of

the nozzle, the agreement between the ![]() atomisation model and experimental

radial droplet mean diameter distributions is satisfactory with good prediction

of the droplet size at the spray periphery but higher than the value predicted

at position 60 mm axial distance from the nozzle exit. The rate of increase of

droplet size with radial distance is correct and the size of the largest

droplet at the spray periphery is well predicted. There is also a good

agreement between the radial positions at 100 mm downstream of the nozzle for

the model and the measurement with the droplet SMD having a slight

under-prediction of less than an average of 3%. The result at this axial

position also shows that most of the predicted SMDs near the inner region of

the spray are below the experimental values. In addition, the SMD increases at

similar rates with radial distances for both results at this axial position.

The radial profiles for the mean droplet sizes (SMDs) between the calculations

and the experiments at the axial position 120 mm from the exit of the nozzle

are closer with the SMD being small near the centreline of the spray and SMD

reasonably predicted. The trend of increasing droplet size with radial distance

is observed and agrees with the work of many researchers in predicting the mean

drop sizes from a pressure swirl atomizer Lefebvre and Wang (1987), Emekwuru and Watkins (2010). The mean drop

diameter of the experimental results of the largest droplet at the periphery of

the spray is higher than its predicted values. However, the SMD at a radial

distance near the spray centreline is closely predicted in relation to the

measurements. The more uniform and continuously increasing Sauter mean diameter

with radial distance may be attributed to the farthest axial distance from

which the drop sizes were measured and may also be due to the coalescence of

smaller droplets and this has been accounted for in the model. The small drop

sizes observed around the spray symmetry axis may be attributed to collisions

between the liquid droplets and aerodynamic drag interactions with the

entrained air as a result of the hollow cone spray

pattern emanating from the nozzle Lefebvre and Wang (1987). The

collisions result in unstable interactions between the drops and in turn lead

to the breaking down of droplets smaller than their original sizes. This is

also supported by the observation made by Yoon et al. (2011) that the

separation of small droplets near the centreline arises due to the complex

interaction between fluctuating turbulent length scales and air entrainment.

This causes the mean gas motion to drive the smaller droplets towards the

centreline of the spray. Larger droplets follow more ballistic trajectories

subject to initial velocity vectors resulting from the liquid sheet breakup

process and turbulent dispersion since they are not affected much by the air

entrainment. However, in the downward part of the spray, the inward entrainment

velocities are decreased to the point where smaller droplets are significantly

dispersed from the centre line. Overall, the computational predictions of SMD

for

atomisation model and experimental

radial droplet mean diameter distributions is satisfactory with good prediction

of the droplet size at the spray periphery but higher than the value predicted

at position 60 mm axial distance from the nozzle exit. The rate of increase of

droplet size with radial distance is correct and the size of the largest

droplet at the spray periphery is well predicted. There is also a good

agreement between the radial positions at 100 mm downstream of the nozzle for

the model and the measurement with the droplet SMD having a slight

under-prediction of less than an average of 3%. The result at this axial

position also shows that most of the predicted SMDs near the inner region of

the spray are below the experimental values. In addition, the SMD increases at

similar rates with radial distances for both results at this axial position.

The radial profiles for the mean droplet sizes (SMDs) between the calculations

and the experiments at the axial position 120 mm from the exit of the nozzle

are closer with the SMD being small near the centreline of the spray and SMD

reasonably predicted. The trend of increasing droplet size with radial distance

is observed and agrees with the work of many researchers in predicting the mean

drop sizes from a pressure swirl atomizer Lefebvre and Wang (1987), Emekwuru and Watkins (2010). The mean drop

diameter of the experimental results of the largest droplet at the periphery of

the spray is higher than its predicted values. However, the SMD at a radial

distance near the spray centreline is closely predicted in relation to the

measurements. The more uniform and continuously increasing Sauter mean diameter

with radial distance may be attributed to the farthest axial distance from

which the drop sizes were measured and may also be due to the coalescence of

smaller droplets and this has been accounted for in the model. The small drop

sizes observed around the spray symmetry axis may be attributed to collisions

between the liquid droplets and aerodynamic drag interactions with the

entrained air as a result of the hollow cone spray

pattern emanating from the nozzle Lefebvre and Wang (1987). The

collisions result in unstable interactions between the drops and in turn lead

to the breaking down of droplets smaller than their original sizes. This is

also supported by the observation made by Yoon et al. (2011) that the

separation of small droplets near the centreline arises due to the complex

interaction between fluctuating turbulent length scales and air entrainment.

This causes the mean gas motion to drive the smaller droplets towards the

centreline of the spray. Larger droplets follow more ballistic trajectories

subject to initial velocity vectors resulting from the liquid sheet breakup

process and turbulent dispersion since they are not affected much by the air

entrainment. However, in the downward part of the spray, the inward entrainment

velocities are decreased to the point where smaller droplets are significantly

dispersed from the centre line. Overall, the computational predictions of SMD

for ![]() atomisation model shows a very

good agreement with most of the experimental measurements in the radial

positions when standard k-ɛ turbulence was used. However, more

divergence was observed between the

predictions and the experimental measurements when the RNG k-ɛ turbulence

model and Realizable k-ɛ turbulence model were used in the predictions as shown

in Figure 7 and Figure 8.

atomisation model shows a very

good agreement with most of the experimental measurements in the radial

positions when standard k-ɛ turbulence was used. However, more

divergence was observed between the

predictions and the experimental measurements when the RNG k-ɛ turbulence

model and Realizable k-ɛ turbulence model were used in the predictions as shown

in Figure 7 and Figure 8.

Figure 6

|

Figure

6 Validation of Droplet SMD, Model

with Experiment, Standard k-ɛ Turbulence Model |

Figure 7

|

Figure

7 Validation of Droplet SMD, Model

with Experiment, RNG k-ɛ Turbulence Model |

Figure 8

|

Figure

8 Validation of Droplet SMD, Model

with Experiment, Realizable k-ɛ Turbulence Model |

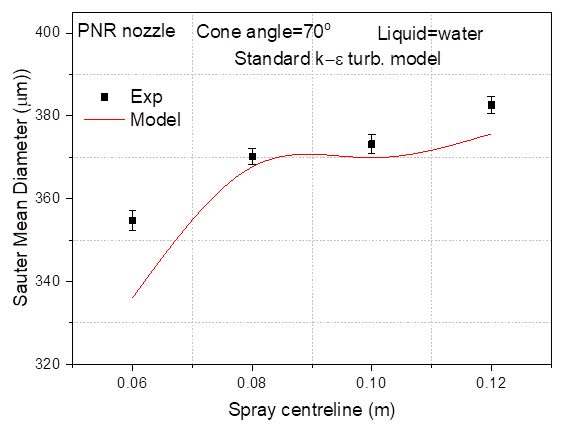

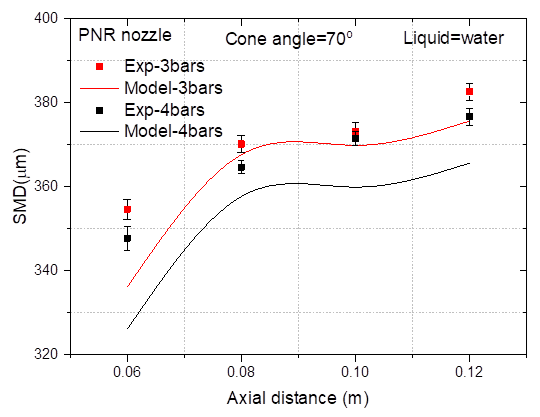

Figure 9 illustrates

the validation of the model with the experimental results on the spray

centreline. It can be observed that the model has good agreement with the

measurements with a percentage error of less than an average of 5% between the

model and the experiments at axial distances of 60 mm and 120mm. Better

predictions are observed at axial distances 80mm and 100mm. Figure 10 shows more

clearly how sensitive SMD is to the pressure differentials. This is because as

pressure increases the faster maximum growth rate of the liquid film occurs and

will lead to the linear stability of the surface wave of the thread film

getting worse. So, the interaction between the liquid phase and the gas phase

becomes stronger and the film can break up more easily. This will make the

droplet SMD get smaller as pressure increases.

Figure 9

|

Figure

9 Validation of SMD at Spray Centre

Axis, Model, and Experiment |

Figure 10

|

Figure

10 Effect of Pressure on SMD, Model

and Experiment |

4. CONCLUSIONS

A validation

of mean drop sizes at both centreline and radial positions was performed using

laser-diffraction-based drop size measurement and ![]() atomization model. It is shown

that the model predictions have good agreement with the experimental measurements

when standard k-ɛ turbulence was used. The experimental results are also

consistent with the model predictions when the effect of pressure differential

on the SMD was analysed. In all, it can be concluded that the computational

predictions of SMD for the

atomization model. It is shown

that the model predictions have good agreement with the experimental measurements

when standard k-ɛ turbulence was used. The experimental results are also

consistent with the model predictions when the effect of pressure differential

on the SMD was analysed. In all, it can be concluded that the computational

predictions of SMD for the ![]() atomization

model shows good validation with the experimental measurements.

atomization

model shows good validation with the experimental measurements.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Beheshti, N., Burluka, A. A., and Fairweather, M. (2007). Assessment of Σ− Y liq Model Predictions for Air-Assisted Atomisation. Theoretical and Computational Fluid Dynamics, 21, 381-397. https://doi.org/10.1007/s00162-007-0052-3.

Belhadef, A., Vallet, A., Amielh, M., and Anselmet, F. (2012). Pressure-Swirl Atomization : Modeling and Experimental Approaches. International Journal of Multiphase Flow, 39, 13-20. https://doi.org/10.1016/j.ijmultiphaseflow.2011.09.009.

Bishop, R. (1975). Thermo-Fluid Dynamic Theory of Two-Phase Flow. IOP Publishing. https://doi.org/10.1088/0031-9112/26/12/034.

Crowley, J. M., Wright, G. S., and Chato, J. C. (1990). Selecting a Working Fluid to Increase the Efficiency and Flow Rate of an EHD Pump. IEEE Transactions on Industry Applications, 26(1), 42-49. https://doi.org/10.1109/28.52672.

Cui, J., Lai, H., Li, J., and Ma, Y. (2017). Visualization of Internal Flow and the Effect of Orifice Geometry on the Characteristics of Spray and Flow Field in Pressure-Swirl Atomizers. Applied Thermal Engineering, 127, 812-822. https://doi.org/10.1016/j.applthermaleng.2017.08.103.

Dafsari, R. A., Lee, H. J., Han, J., Park, D. C., and Lee, J. (2019). Viscosity Effect on the Pressure Swirl Atomization of an Alternative Aviation Fuel. Fuel, 240, 179-191. https://doi.org/10.1016/j.fuel.2018.11.132.

Dafsari, R. A., Vashahi, F., and Lee, J. (2017). Effect of Swirl Chamber Length on the Atomization Characteristics of a Pressure-Swirl Nozzle. Atomization and Sprays, 27(10), 859-874. https://doi.org/10.1615/AtomizSpr.2017024777.

Drew, D. A. (1983). Mathematical Modeling of Two-Phase Flow. Annual Review of Fluid Mechanics, 15, 261-291. https://doi.org/10.1146/annurev.fl.15.010183.001401.

Emekwuru, N., and Watkins, A. P. (2010). Analysis of a Two-Fluid Sprayer and its Use to Develop the Number Size Distribution Moments Spray Model, Part II :Computational Analysis. Atomization and Sprays, 20(6), 467-484. https://doi.org/10.1615/AtomizSpr.v20.i6.10.

Gharbi, A., Ruffin, A., Anselmet, F., and Schiestel, R. (1996). Numerical Modelling of Variable Density Turbulent Jets. International Journal of Heat and Mass Transfer, 39(9), 1865-1882. https://doi.org/10.1016/0017-9310(95)00290-1.

Hu, J., Liu, B., Zhang, C., Gao, H., Zhao, Z., Zhang, F., Wang, Y. (2019). Experimental Study on the Spray Characteristics of an Air-Assisted Fuel Injection System Using Kerosene and Gasoline. Fuel, 235, 782-794. https://doi.org/10.1016/j.fuel.2018.08.083.

Khani Aminjan, K., Kundu, B., and Ganji, D. (2020). Study of Pressure Swirl Atomizer with Tangential Input at Design Point and Outside of Design Point. Physics of Fluids, 32(12), 127113. https://doi.org/10.1063/5.0032174.

Lefebvre, A. H., and McDonell, V. G. (2017). Atomization and Sprays. CRC press. https://doi.org/10.1201/9781315120911.

Lefebvre, A., and Wang, X. (1987). Mean Drop Sizes from Pressure-Swirl Nozzles. Journal of Propulsion and Power. 3(1), 11-18. https://doi.org/10.2514/3.22946.

Lin, J., Qian, L., Xiong, H., and Chan, T. L. (2009). Effects of Operating Conditions on Droplet Deposition onto Surface of Atomization Impinging Spray. Surface and Coatings Technology, 203(12), 1733-174. https://doi.org/10.1016/j.surfcoat.2009.01.009.

Liu, C., Liu, F., Yang, J., Mu, Y., Hu, C., and Xu, G. (2019). Experimental Investigations of Spray Generated by a Pressure Swirl Atomizer. Journal of the Energy Institute, 92(2), 210-221. https://doi.org/10.1016/j.joei.2018.01.014.

Liu, Z., Huang, Y., and Sun, L. (2017). Studies on Air Core Size in A Simplex Pressure-Swirl Atomizer. International Journal of Hydrogen Energy, 42, 18649-18657. https://doi.org/10.1016/j.ijhydene.2017.04.188.

Malvern-Instruments (2007). Spraytec User Manual MAN0368. Issue.

Malý, M., Sapík, M., Jedelský, J., Janáčková, L., Jícha, M., Sláma, J., Wigley, G. (2018). Internal Flow Characteristics in Scaled Pressure-Swirl Atomizer. EPJ Web of Conferences. 02059. https://doi.org/10.1051/epjconf/201818002059.

Mirjalili, S., Jain, S. S., and Dodd, M. (2017). Interface-Capturing Methods for Two-Phase Flows : An Overview and Recent Developments. Center for Turbulence Research Annual Research Briefs, 117-135.

Ortman, J., and Lefebvre, A. (1985). Fuel Distributions from Pressure-Swirl Atomizers. AIAA Journal of Propulsion and Power, 1(1), 11-15. https://doi.org/10.2514/3.22752.

Rashad, M., Yong, H., and Zekun, Z. (2016). Effect of Geometric Parameters on Spray Characteristics of Pressure Swirl Atomizers. International Journal of Hydrogen Energy, 41(35), 15790-15799. https://doi.org/10.1016/j.ijhydene.2016.04.037.

Shin, D., Bokhart, A. J., Rodrigues, N. S., Sojka, P., Gore, J. P., and Lucht, R. P. (2019). Experimental Study of Spray Characteristics at Cold Start and Elevated Ambient Pressure Using Hybrid Airblast Pressure-Swirl Atomizer. AIAA Scitech 2019 Forum, 1737. https://doi.org/10.2514/6.2019-1737.

Trask, N. A. (2010). Implementation of an Eulerian Atomization Model to Characterize Primary Spray Formation. Masters Theses, 434.

Vallet, A., Burluka, A.A., and Borghi, R. (2001). Development of a Eulerian Model for the "Atomization" of a Liquid Jet. Atomization and Sprays, 11(6). https://doi.org/10.1615/AtomizSpr.v11.i6.20.

Wimmer, E., and Brenn, G. (2012). Viscous Effects on Flows Through Pressure-Swirl Atomizers. In Proceedings of the 12th Triennial International Conference on Liquid Atomization and Spray Systems (ICLASS 2012), Heidelberg, Germany. 2-6.

Wu, S., Gandhi, A., Li, H., and Meinhart, M. (2020). Experimental and Numerical Study of the Effects of Nozzle Taper Angle on Spray Characteristics of Gdi Multi-Hole Injectors at Cold Condition. Fuel, 275, 17888. https://doi.org/10.1016/j.fuel.2020.117888.

Xiong, H. B., Lin, J. Z., and Zhu, Z. F. (2009). Three-Dimensional Simulation of Effervescent Atomization Spray. Atomization and Sprays, 19(1), 75-90. https://doi.org/10.1615/AtomizSpr.v19.i1.50.

Yoon, S. H., Kim, D. K., and Kim, B. H. (2011). Effect of Nozzle Geometry for Swirl Type Twin-Fluid Water Mist Nozzle on the Spray Characteristic. Journal of Mechanical Science and Technology, 25, 1761. https://doi.org/10.1007/s12206-011-0506-9.

Zhang, T., Dong, B., Chen, X., Qiu, Z., Jiang, R. and Li, W. (2017). Spray Characteristics of Pressure-Swirl Nozzles at Different Nozzle Diameters. Applied Thermal Engineering, 121, 984-991. https://doi.org/10.1016/j.applthermaleng.2017.04.089.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© IJETMR 2014-2022. All Rights Reserved.