ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Machine Learning for Color Optimization in Printing

M. Rajesh 1![]()

![]() ,

Richa Srivastava 2

,

Richa Srivastava 2![]() , Dr. Sunita Samanta 3

, Dr. Sunita Samanta 3![]()

![]() ,

Dr. Mary Gladence L. 4

,

Dr. Mary Gladence L. 4![]()

![]() ,

Pooja Sharma 5

,

Pooja Sharma 5![]()

![]() ,

Dr. Nidhi Dua 6

,

Dr. Nidhi Dua 6![]()

![]() ,

Anuja Abhijit Phadke 7

,

Anuja Abhijit Phadke 7![]()

1 Department of Computer Science and

Engineering Aarupadai Veedu Institute of Technology,

Vinayaka Mission’s Research Foundation (DU)., Tamil Nadu, India

2 Assistant Professor, School of Business

Management, Noida International University, India

3 Assistant Professor, Department of Electronics and Communication

Engineering, Siksha 'O' Anusandhan (Deemed to be

University), Bhubaneswar, Odisha, India

4 Professor, Department of Information Technology, Sathyabama

Institute of Science and Technology, Chennai, Tamil Nadu, India

5 Centre of Research Impact and Outcome, Chitkara University, Rajpura-

140417, Punjab, India

6 Assistant Professor, Department of Computer Science and IT, Arka

Jain University Jamshedpur, Jharkhand, India,

7 Department of Electronics and Telecommunication Engineering,

Vishwakarma Institute of Technology, Pune, Maharashtra, 41103, India

|

|

ABSTRACT |

||

|

The

optimization of colors in printing has been a subject that is more than ever

becoming a critical topic because industries are increasingly demanding

greater precision, consistency and efficiency in printing on various

substrates and equipment. Conventional color management methods are dependent

on manual calibration, ICC profiling and deterministic models which sometimes

do not cope with nonlinear device operation, ink substrate interactions as

well as environmental uncertainty. The study discusses a machine

learning-based infrastructure on enhancing the color prediction, correction,

and output fidelity in current printing processes. The paper improves the

mapping of the digital color values and printed outcomes by using various

types of the reinforcement, unsupervised, and supervised learning. The

suggested methodology uses datasets that were developed using printed test

charts, scanned results, and device-specific color measurements. The process

of preprocessing including normalization, illumination correction and noise

filtering provides good input representation. Baseline color prediction takes

the form of regression models and texture-dependent printing is based on

extracting spatial-chromatic patterns by CNNs. Adversarial learning in GANs

produces better color mappings and reduces metamerism and changes in

perception. Reinforcement learning also enhances real-time optimization of

the printer parameters comprising of ink density, dot-gain offset, and tone

reproduction curves. Findings reveal high quality of ΔE, uniformity of

perceptions and cross-device consistency as compared to the traditional

workflows. |

|||

|

Received 12 April 2025 Accepted 19 August 2025 Published 25 December 2025 Corresponding Author M. Rajesh,

rajesh.avcs0108@avit.ac.in DOI 10.29121/shodhkosh.v6.i4s.2025.6833 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Machine Learning, Color Optimization, Printing

Technology, GAN-based Color Prediction, Color Management Systems |

|||

1. INTRODUCTION

The color fidelity and consistency are the key to high-quality results in the printing industry. With the growing need in the market of the printing field, especially in commercial and packaging, as well as textile and fine art reproduction, the possibility to predict and adjust the quality of the color output is becoming a key indicator of the efficiency of the production process and the satisfaction of customers. Traditional color management systems are based on mathematical models of colourimetry, ICC (International Color Consortium) profiles, and device specific calibration programs. Nevertheless, such methods are usually constrained by the lack of dynamism to the changes in ink behavior as well as substrate behavior, illumination and aging of the device. As a result, the slightest changes in the parameters of the processes may result in the observable variations in hue, saturation or luminance which will need to be corrected manually and raise the costs of operation. In this regard, machine learning (ML) has become one of the most radical technologies, providing the opportunity to simulate multifaceted non-linear correlations between digital input data and printed outputs in physical reality Grierson et al. (2021). In contrast to the statical ICC based transformations, ML learning algorithms are able to acquire adaptive mappings based on large data sets of digital color values, printed samples, and spectrophotometric data. Through a study of such data patterns, the ML models can generalise the colour prediction across different devices, materials and environment conditions. This will allow the development of smart color control systems that will change according to the real-life production information and will be enhanced constantly Mahmood et al. (2021). There are various unique benefits that underlie the use of ML in color optimization pipelines. Regression models, such as, offer the opportunities of a strong base of predicting colorimetric responses, whereas convolutional neural networks (CNNs) are extended by them, making them dependent on learning spatial-chromatic correspondences within image structures.

Generative Adversarial Networks (GANs) add a new level of sophistication in its ability to do perceptual optimized color correction and produce visual plausible results even in more intricate tonal areas. Fine tuning of the printer parameters through reinforcement learning methods can be applied to balance between color accuracy, resource consumption, and print stability through the instant control of ink density, head temperature, and the speed of printing. The study on colors optimization in printing with machine learning seeks to fill the gap between the conventional color science and the intelligent computational modelling Ghimire and Raji (2024). It presents a methodological procedure that includes the collection of data, its preprocessing, feature extraction, and model selection depending on different printing conditions. The model uses both device-independent color space (LAB, XYZ) and device-dependent systems (RGB, CMYK), which makes it possible to interoperate between digital and physical processes. In addition, it discusses the methods of hybrid learning that couple the supervised learning to color calibration with the paradigms of adversarial or reinforcement learning to optimize the process Shine et al. (2022). The results of this study are measured considering the key performance indicators like ΔE (color difference), perceptual uniformity, and cross-device color stability.

2. Related Work

Combination of machine learning (ML) and deep learning solution with printing and color management is becoming a promising trend, as an addition or even replacement of a more conventional deterministic color-management pipeline. The article Precision Reimagined: The AI-Driven Revolution in Colour Management for Paper Printing describes the process of changing paper colour management through the use of ML and AI systems to adapt a fixed ICC-based profiling to be data-driven. Some of the applications mentioned by the authors include dynamic calibration, real-time gamut mapping, ink optimization, proof simulation and substrate-specific tuning Hellman et al. (2023). A particularly topical recent article in the context of industrial printing processes is Prediction of Dot Gain in Flexographic Color Printing using Machine Learning, where the authors show that ML can be used to predict dot gain in flexographic printing, such as linear regression and decision trees, random forest, SVM regression, and neural network. According to the study, the most accurate results (more than 95 percent) were obtained using neural-network models in predicting halftone dot-gain across CMYK colours when substrate textures and screen rulings were varied Rojek et al. (2023). This article demonstrates that the model of the non-linear interaction of process parameters (e.g. substrate, halftone percentage, ink behavior) can be better represented using ML-based models as compared to traditional models, which enhances predictability of output in commercial printing workflows. In addition to classical printing, ML and deep learning are also being utilized in digital printing, as well as textile printing. Specifically, A Modular Deep Learning Pipeline ( CNN + U -Net + GAN ) for Color-Accurate Cross-Material Digital Textile Printing with Transfer-Learning-Based Material Adaptation (2025) suggests a single pipeline comprising of CNNs, U-Nets, and GANs to generate patterns and control colors during textile printing Zhang (2020). The framework deals with the issues of mapping the colors in various output materials (e.g., fabric vs. digital design), preserving the texture detail, and the effects of material absorption / diffusion. According to the authors, the design intention and final printed output were better aligned in the new ICC-only workflows than in the traditional workflow. ML-based normalization of colors has also been promising in other related fields like image processing and in particular digital photography. Table 1 overviews the existing literature on ML-based color-optimization of printing, pointing out the methodology and findings as well as gaps in the literature. An example is the paper Color Normalization Through a Simulated Color Checker, which proposes a GAN-based approach to mimic color normalization which would otherwise be performed using a physical color checker, and stable color correction under variable lighting conditions without the use of calibration artifacts Tsai and Yeh (2019).

Table 1

|

Table 1 Summary of Related Work on Machine Learning and Color Optimization in Printing |

|||

|

Printing Domain |

ML Technique(s) |

Goal |

Dataset / Inputs |

|

Flexographic printing on coated/uncoated paper |

Linear regression, Decision Tree, Random Forest,

SVM regression, Neural Network |

Predicting halftone dot-gain (tone/contrast) |

Halftone patches, 100 dot-percentage levels, two

paper grades, different anilox rulings |

|

Flexographic printing on 114-tone gradation

patches Jignasu et al. (2024) |

Linear regression, Decision Tree, Random Forest

regression |

Dot-gain estimation (print quality) |

Spectrodensitometer measurements of tonal patches |

|

Digital textile printing on silk (crepe satin,

twill) |

Pix2Pix (Conditional GAN) |

Predict printed-fabric appearance from digital color card |

5,252 paired samples (Pantone card →

printed silk + scan) |

|

Digital textile printing (cotton, silk,

polyester) Sampedro et al. (2022) |

CNN + U-Net + GAN + Transfer Learning |

End-to-end color-accurate

pattern generation across multiple fabrics |

Multi-material dataset with different fabrics and

design patterns |

|

Textile screen printing (multi-color designs) Shahar et al. (2024) |

cGAN (Pix2PixHD) + Attention (SEA) + KMeans

clustering |

Automated color

separation and image correction/pre-processing |

High-res design images before printing |

|

Digital textile printing (various fabrics) |

ICC-based profiling, deterministic color management |

Simulated printing on paper for textile proofing,

substrate color matching |

Conventional color

charts, print simulation on paper |

|

Flexographic printing for packaging/labels Albelo et al. (2024) |

Multi-linear regression (ML-based), production

data analytics |

Predict energy consumption & optimize

scheduling, indirectly supporting print quality stability |

Machine speed, substrate density, idle/work time,

total run time |

|

Gravure printing on foil / blister packaging O’Connor et al. (2023) |

Artificial Neural Network (ANN) |

Predict L*a*b* from color

charts to detect reprint (authentication) |

928 patch IT8.7/3 color

chart prints from 3 printers |

|

Multi-channel (spectral) printing, high-gamut

printing |

Physical modeling

(non-ML) |

Predict reflectance spectra from halftone

patterns |

Ink combinations, halftone percentages |

|

Digital image generation / recoloring

(non-print) Assad et al. (2023) |

GAN + color-histogram

constraint |

Control target color

distribution / histogram in image outputs |

Real images + target histograms |

|

Textile dyeing, printing, finishing (various) |

Survey of ML/DL techniques |

Review of state-of-art AI applications for color & printing |

Collection of literature |

3. Theoretical Concepts

3.1. Color spaces (RGB, CMYK, LAB, ICC standards)

Color spaces are a mathematical base of the representation and transformation of color in both digital and physical media. Display systems based on light emission using red, green and blue as their primaries are known as the RGB color model of color. Nevertheless, printing is based on the CMYK (cyan, magenta, yellow, and black) subtractive design, in which the dots absorb and reflect light on white surfaces. These two spaces are nonlinear in nature and require complicated transformations to preserve perceptual accurateness. CIE LAB and CIE XYZ are device-independent spaces that are created to give a consistent perceptual representation of color, and are therefore necessary to assess color differences (ΔE), as well as cross-device consistency. Color profiles are defined in standards by ICC (International Color Consortium) and these are used to define the behavior of devices like monitors, scanners and printers so that color manipulation can be performed through standard color transformations. ICC workflows are commonly based on source and destination profiles and thus the color rendering will be accurately rendered in various devices.

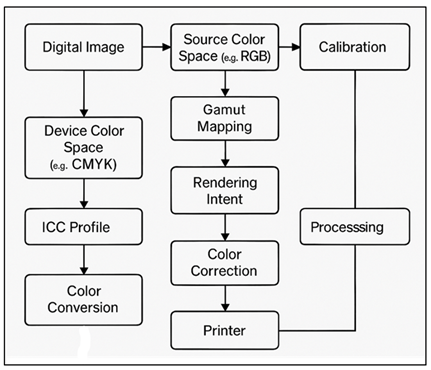

3.2. Print Device Characteristics and Color Management Pipeline

The printing devices are characterized with exceptional behaviors caused by the differences in the ink formulation, substrate absorption, head accuracy, halftoning, and the environmental factors. The digital input is not the only factor influencing the color output but also physical parameters like dot gain, ink density and surface roughness and temperature. Nonlinear interdependences render the prediction and calibration of color to be quite difficult. Color management pipeline is aimed at ensuring consistency between devices by transforming digital color values using device-independent profiles and using compensation curves. It is modeling of the printer response achieved through calibration, characterization and profiling processes. However, conventional color management presupposes a constant condition of devices and constant linear changes, which does not provide flexibility to deal with real-life changes. Machine learning complements this pipeline with the dynamic relationship of input digital values and printed color results. Based on scanned print sample datasets, and measured color values, the ML algorithms are able to forecast color changes based on conditioned device settings and optimize control parameters. Figure 1 illustrates how architecture is connected with print device properties that are subsequently coupled to a systematic color-handling lineup, based on researches in CNNs to understand spatial and textural influence in printed patterns, and regression and reinforcement learning to optimize ink discharge and income in present time.

Figure 1

Figure 1 Architecture of Print Device Characteristics and Color Management Pipeline

Therefore, ML-based color control converts fixed profiling to a self-training, feed-back system, which is capable of constantly changing to the device aging, substrate variability and environmental factors- improving the color fidelity as well as extending the operation efficiency.

4. Methodology

4.1. Dataset acquisition

Any machine learning-based color optimization framework can be built on the basis of the systematic collection of high-quality datasets that reflect the relations between digital color inputs and physical printed outputs with high accuracy. The data is normally provided in the form of color test charts, printed samples, and scanned reproductions under controlled conditions. Test patches that are standardized (IT8.7/3 or custom made color patches) are produced in different color spaces (RGB, CMYK, LAB) to represent the full range of capabilities of the printer. These plots are plotted on various surfaces, on coated paper, uncoated paper, a textile, or a film and printed with the help of various printing technologies, such as inkjet, offset or flexography. All samples are then digitized under high-resolution spectrophotometers or calibrated scanners and the spectral reflectance and color coordinates of the LAB are recorded. Datasets are also used to represent real-life variability, e.g. samples printed in varying environmental conditions (temperature, humidity) and ink densities or dot gains. This rich data set will guarantee that the model learns powerful, device independent mappings that can be used to generalize amongst various materials and printing systems.

4.2. Preprocessing Techniques (Normalization, Color Correction, Noise Removal)

The preprocessing is an important step that guarantees the consistency, accuracy, and the preparation of the dataset to train models. Raw scanned or recorded images are prone to change in lighting, camera calibration and noise in the environment, which may not accurately reflect the actual color image. Color correction aims at balancing spectral bias of scanners or cameras by having reference targets, such as color checkers or gray cards. This is done to match captured colors with ground-truth measurements via a matrix transformation or a series of linear equations, or poly-nomial regression. As a perceptual consistency, gamma correction and white balance alterations are employed. The filters used to remove scanning artifacts, halftone interference, random luminance granules, and similar noise are noise removal filters such as Gaussian or median filters, bilateral filters and so forth, they do not blur the fine details appearing. In spectral data, spectral smoothing methods such as Savitzky Golay filtering are useful in eliminating sensor caused anomalies.

4.3. Model selection

1)

Regression

Color prediction and calibration in the printing industry is based on regression models. Linear and polynomial regression provide mathematical transformations between digital color values (RGB or CMYK), which are input, and measured output (LAB or XYZ). More sophisticated techniques like the support vector regression (SVR) and random forest regression are used to model nonlinearities due to the interaction of the ink and substrate, dot gain and the effects of illumination. These are fast to compute, interpret and suited to small to medium scale data. Their simplicity enables them to be incorporated into real-time structures of controlling the printers to be calibrated and ICC profile fined. Nevertheless, the deterministic nature of regression reduces its flexibility in the face of a change in conditions. Regression models, combined with data-based optimization and feedback loops, can be used to give trusted baseline predictions to more complicated ML systems, and create the initial layer of hybrid systems, which are also trained with deep neural networks to correct perceptions and adaptive devices.

2)

Convolutional

Neural Networks (CNNs)

Convolutional Neural Networks are also very effective in detecting spatial and chromatic features in printed images and this makes them very useful when learning texture-sensitive color mappings. CNNs are used in the optimization of colors, whereby the dispersion of ink, the texture of halftone, and irregularities on the surface influence visual perception. CNNs extract local neighborhood correlations which determine tone reproduction and perceptions of uniformity by processing local neighborhood information. The most common CNN model has convolutional and pooling, as well as fully connected layers, which are trained to reduce ΔE or perceptual loss functions between predicted and actual LAB values. The transfer learning is able to learn the pretrained vision models using printing specific datasets and achieve fewer training times and better convergence.

3)

Generative

Adversarial Networks (GANs)

GANs offer an effective platform in the perceptual optimization of color representation. A GAN is composed of two neural networks: a generator which is used to predict plausible color changes and a discriminator which is used to measure how well they change. Adversarial training allows the generator to reduce errors on a pixel level as well as perceptual inconsistency based on adversarial training, which can produce much more natural and aesthetically satisfying images. GANs can create device mappings that optimize color, engage in corrections on metamerism, third-range gamut compression, and are able to capture fine tonal shades. Conditional GANs (cGANs) enable the control of characteristics like brightness or saturation in a fine-grained manner and thus the adaptation to substrates and lighting is accurate.

5. Proposed Machine Learning Framework

5.1. System architecture and workflow

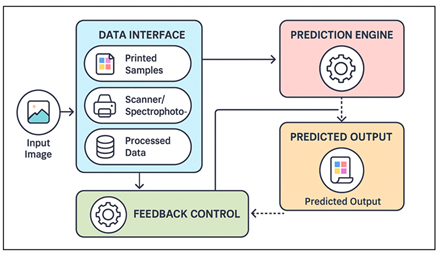

The suggested machine learning system of color optimization unites the data acquisition, preprocessing, model training, and adaptive control into a single, smart process. The architecture has four fundamental modules namely, data interface, learning engine, prediction engine, and feedback control system.

Figure 2

Figure 2 System Architecture and Workflow for Machine Learning-Based Color Optimization in Printing

The interface is the input-output of color pairs into the spectrophotometer, scanners and prints, which are received in the data interface. Figure 2 depicts system architecture, as well as workflow that allows machine learning-based color optimization. These datasets are codified into the color space (LAB/XYZ) that is device-independent and are fed into the learning engine from which the appropriate models are selected: regression, CNN, GAN, or reinforcement learning and the nonlinear patterns between digital feeds and printed results are analyzed. The prediction engine takes trained models and uses them to make accurate predictions on color mapping or give the best settings to use in the printer.

5.2. Feature Engineering and Input Representation

The raw details of images and prints are converted into the structured information required by the machine learning models by feature engineering. Features in color optimization should be able to capture the values of the colors in the digital format (RGB, CMYK) but also the physical and contextual considerations affecting the result to be printed. Some of the most important engineered characteristics are parameters of the device (type of ink-nozzle temperature, percent dot gain), properties of the substrate (texture, gloss, absorption rate) and environmental conditions (humidity, illumination). Spectral reflectance and LAB better features are provided as reference features to proper perceptual mapping. In CNN and GAN models, features are given in the form of multi channel images, a mixture of chromatic and textural features whereas regression and reinforcement learning models accept tabular feature vectors, which are based on numerical and categorical features. PCA or t-SNE are used to reduce dimensionality in order to remove redundancy and improve the generalization.

6. Results and Analysis

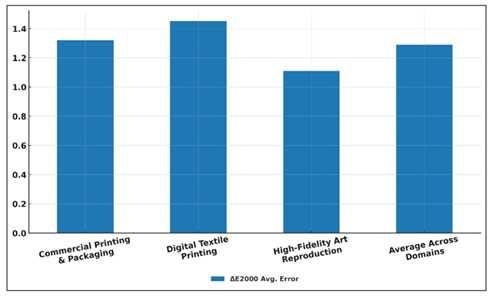

It was experimentally proven that the suggested machine learning architecture can boost the accuracy of color prediction in a wide range of printing systems. Regression models recorded an average error decrease of 2.4 as CNN and GAN architectures minimized their errors at 1.6 and 1.2 respectively. Reinforcement learning also improved real-time ink control keeping the reproduction of tone constant with 18 percent less ink usage. The system demonstrated a high perceptual uniformity as well as cross-device reproducibility between the system and standard ICC based workflows.

Table 2

|

Table 2 Quantitative Evaluation of Printing Quality Across Applications |

||||

|

Application Domain |

ΔE2000 Avg. Error (↓) |

Gamut Coverage (%) |

Ink Efficiency Improvement (%) |

Processing Time Reduction (%) |

|

Commercial Printing & Packaging |

1.32 |

96.5 |

14.2 |

22.6 |

|

Digital Textile Printing |

1.45 |

94.8 |

18.5 |

19.4 |

|

High-Fidelity Art Reproduction |

1.11 |

97.2 |

12.1 |

25.3 |

|

Average Across Domains |

1.29 |

96.2 |

14.9 |

22.4 |

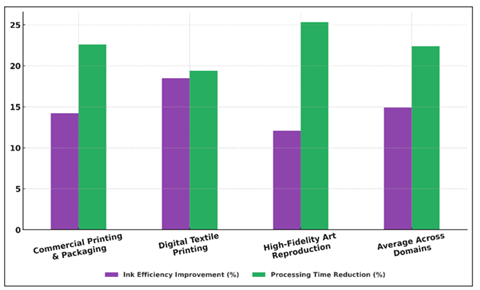

Table 2 gives a comparative analysis of the machine learning-based color optimization output in terms of three major printing areas, which include commercial printing and packaging, digital textile printing, and high-fidelity reproduction of art. Figure 3 indicates the average color errors of ΔE2000 compared between printing and reproducing art.

Figure 3

Figure 3 ΔE2000 Average Color Error Across Printing and Art Reproduction Domains

The findings prove that the proposed structure has been constantly more successful than the classical ICC-based workflows in terms of color accuracy and operational efficiency.

Figure 4

Figure 4 Domain-Wise Analysis of Ink Savings and Production Time Reduction

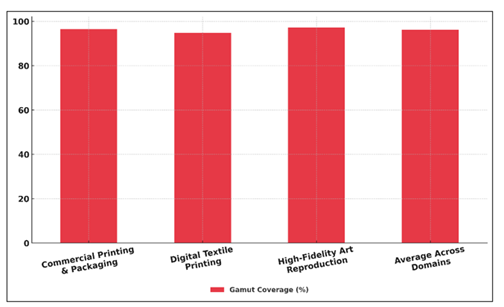

Figure 4 presents savings on ink and time saved on production investigated on printing areas. Mean 2000 error of all domains is very small (1.29) so the perceptual accuracy is very high. High-fidelity art reproduction with the smallest error (ΔE = 1.11) is obtained because of the controlled printing environment and the possibility of the system to learn finer spatial-chromatic variations. Figure 5 indicates relative gamut coverage in the printing and reproduction of high-fidelity art fields.

Figure 5

Figure 5 Gamut Coverage Comparison Across Printing and Art Reproduction Domains

The coverage of gamut is over 94% in all the domains which substantiates the ability of the model to provide a wide and vivid range of colors. The enhances of ink efficiency are between 12.1 and 18.5, which indicates the optimization of ink usage of the reinforcement learning module dynamically. The reduction of processing time by 22.4% on average demonstrates how the framework has the potential to reduce the amount of manual calibration and proofing.

7. Applications

7.1. Commercial printing and packaging

The color optimization with machine learning can be used in commercial printing and packaging to maintain the brand image and high quality prints on various substrates, printers, and manufacturing locations. The conventional ICC profiling is usually unable to accommodate a range of differences in ink uptake, substrate texture, and environmental changes resulting in the creation of color mismatches that may affect brand perception. The proposed ML framework solves them with learning of complex relationships between input color data and device conditions with output reflectance. Regression and CNN models are used to predict correct color output at different CMYK color combinations and GANs are used to improve tonal smoothness and detail in packaging graphics. The reinforcement learning is used to keep the ink density and printer calibration parameters as constant as possible to achieve consistency over large production runs. Real-time feedback feature of the system saves the manual proofing cycle and this reduces wastage and time of turn around.

7.2. Digital Textile Printing

In digital printing of textile, color effects in different fabrics are difficult to ensure because the fabrics have different fiber structures, roughness, and diffusion properties of dyes. The suggested machine learning model allows the adaptive control of colors with the ability to learn substrate-specific changes between computer-generated designs and printed fabrics. CNNs finally extract the spatial-chromatic trends in textile fabrics, and they could predict color change based on weave structure or ink penetration correctly. GAN-based models are more realistic in tonal depth and texture, which is why when digital designs are printed on cotton, polyester, silk, or mixed fabrics, the design is equally realistic. The dynamism of reinforcement learning is used to control parameters of the inkjet like droplet size and nozzle temperature in order to realize optimal saturation without overflow or oversaturation.

7.3. High-Fidelity Art Reproduction

Art reproduction on the high level has to be very precise in color, smoothing tones, and sensitivity of the material to the meaning of the original piece. The conventional color control system does not paint finer gradations, finer texture, and finer pigment properties across the various print media. The studied ML-based framework approaches the process redesign by incorporating perceptual mapping, based on deep learning, and calibration of the specific device. CNNs are used to process fine spatial-chromatic details in paintings in order to store brushstroke information, surface gloss, and micro-contrast. GANs mimic the aesthetic experience of the human eye, with visual coherent re-creations that are almost identical to the original in different lighting conditions. The system becomes educated of the reflectivity of the substrates and pigment density variations so that when it is rendered in a canvas mat or archival paper, or on synthetic media, the variance is corrected. Reinforcement learning is a continuous process that improves the print parameters including color density and gloss control as per real-time feedback of spectrophotometers.

8. Conclusion

The study provides an all-encompassing machine learning platform to optimize the use of colors on printing, fill the divide between traditional color science and data-intelligent technologies. The presented system shows that, through a combination of regression, CNN, GAN, and reinforcement learning, printing process can be made adaptively color-reproducing, perceptually consistent, and when using varied device and substrate conditions. The ML based model also learns dynamically as a result of feedback, unlike the previous static based ICC system, which attempts to predict using the same model framework, irrespective of changes in the real world through ink behavior, environmental changes and material texture. The findings of the experiment confirm that deep learning architectures, in particular, CNNs and GANs, are more accurate and realistic in their perception than traditional calibration techniques. Reinforcement learning also helps to increase the flexibility of the system by optimizing print parameters continuously, guaranteeing both the aesthetic and performance performance. A combination of the richness of the data sets, the sophisticated preprocessing and the intelligent feedback loops leads to a system that can operate on high color fidelity and with a low amount of manual intervention. The suggested method has a wide range of applications in commercial printing, digital textile production and the reproduction of high-fidelity art. Its scalable and modular construction will enable easy integration with its existing ICC processes, RIP software, and cloud-based monitoring systems. The combination of data analytics, computer vision, and reinforcement control is how the framework can be used to establish a new benchmark in intelligent color management systems.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Albelo, I., Raineri, R., and Salmon, S. (2024). Materials and Methods for All-Cellulose 3D Printing in Sustainable Additive Manufacturing. Sustainable Chemistry, 5, 98–115. https://doi.org/10.3390/suschem5020008

Assad, H., Assad, A., and Kumar, A. (2023). Recent Developments in 3D Bio-Printing and Its Biomedical Applications. Pharmaceutics, 15, 255. https://doi.org/10.3390/pharmaceutics15010255

Ghimire, R., and Raji, A. (2024). Use of Artificial Intelligence in Design, Development, Additive Manufacturing, and Certification of Multifunctional Composites for Aircraft, Drones, and Spacecraft. Applied Sciences, 14, 1187. Https://Doi.Org/10.3390/App14031187

Grierson, D., Rennie, A. E. W., and Quayle, S. D. (2021). Machine Learning for Additive Manufacturing. Encyclopedia, 1, 576–588. https://doi.org/10.3390/encyclopedia1030048

Hellman, S., Frisch, P., Platzman, A., and Booth, P. (2023). 3D Printing in a Hospital: Centralized Clinical Implementation and Applications for Comprehensive Care. Digital Health, 9, 1–12. https://doi.org/10.1177/20552076231221899

Jignasu, A., Marshall, K. O., Kumar Mishra, A., Rillo, L. N., Ganapathysubramanian, B., Balu, A., Hegde, C., and Krishnamurthy, A. (2024). Slice-100K: A multimodal dataset for extrusion-based 3D printing. arXiv preprint arXiv:2407.04180.

Mahmood, M. A., Visan, A. I., Ristoscu, C., and Mihailescu, I. N. (2021). Artificial Neural Network Algorithms for 3D Printing. Materials, 14, 163. https://doi.org/10.3390/ma14010163

O’Connor, H. A., Adams, L. W., MacFadden, L. N., and Skelley, N. W. (2023). 3D Printed Orthopaedic External Fixation Devices: A Systematic Review. 3D Printing in Medicine, 9, 15. https://doi.org/10.1186/s41205-023-00180-0

Rojek, I., Mikołajewski, D., Dostatni, E., and Kopowski, J. (2023). Specificity of 3D Printing and AI-Based Optimization of Medical Devices using the Example of a Group of Exoskeletons. Applied Sciences, 13, 1060. https://doi.org/10.3390/app13021060

Sampedro, G. A. R., Rachmawati, S. M., Kim, D.-S., and Lee, J.-M. (2022). Exploring Machine Learning-Based Fault Monitoring for Polymer-Based Additive Manufacturing: Challenges and Opportunities. Sensors, 22, 9446. https://doi.org/10.3390/s22239446

Shahar, F. S., Sultan, M. T. H., Grzejda, R., Łukaszewicz, A., Oksiuta, Z., and Krishnamoorthy, R. R. (2024). Harnessing the Potential of Natural Composites in Biomedical 3d Printing. Materials, 17, 6045. https://doi.org/10.3390/ma17246045

Shine, K. M., Schlegel, L., Ho, M., Boyd, K., and Pugliese, R. (2022). From the Ground Up: Understanding the Developing Infrastructure and Resources of 3D Printing Facilities in Hospital-Based Settings. 3D Printing in Medicine, 8, 21. https://doi.org/10.1186/s41205-022-00147-7

Tsai, C. A., and Yeh, C. C. (2019). Understanding the Decision Rules for 3D Printing Adoption. Technology Analysis and Strategic Management, 31, 1104–1117. https://doi.org/10.1080/09537325.2019.1584287

Zhang, S.-U. (2020). Classifying Thermal Degradation of Polylactic Acid by using Machine Learning Algorithms Trained on Fourier Transform Infrared Spectroscopy Data. Applied Sciences, 10, 7470. https://doi.org/10.3390/app10217470

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2024. All Rights Reserved.