ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Automated Layout Design Using AI Systems

Danish Kundra 1![]()

![]() ,

Aarushi Thusu 2

,

Aarushi Thusu 2![]()

![]() ,

Thiagarajan C 3

,

Thiagarajan C 3![]()

![]() ,

Ramesh Sengodan 4

,

Ramesh Sengodan 4![]()

![]() ,

Deepak Minhas 5

,

Deepak Minhas 5![]()

![]() ,

Punam Jagdish Patil 6

,

Punam Jagdish Patil 6![]()

1 Centre

of Research Impact and Outcome, Chitkara University, Rajpura- 140417, Punjab,

India

2 Assistant Professor, Department of Computer Science and Engineering

(AIML), Noida Institute of Engineering and Technology, Greater Noida, Uttar

Pradesh, India

3 Associate Professor, Department of Mechanical Engineering, Aarupadai

Veedu Institute of Technology, Vinayaka Mission’s Research Foundation (DU),

Tamil Nadu, India

4 Professor, Department of Computer Science and Engineering, Presidency

University, Bangalore, Karnataka, India

5 Chitkara Centre for Research and Development, Chitkara University,

Himachal Pradesh, Solan, 174103, India

6 Department of Instrumentation, Bharati Vidyapeeth College of

Engineering, Maharashtra, India

|

|

ABSTRACT |

||

|

Artificial

Intelligence (AI) systems that facilitate the automated layout design are a

major breakthrough in design automation in a variety of areas, including

architecture, industrial design, electronics, and digital interfaces. The

conventional layout design procedures are based on human skills and manual

corrections that are time consuming and can be subject to subjective

judgements. The more recent advances of the AI, especially in machine

learning and deep learning, have allowed systems to create, analyze, and

optimize the layout configurations with little human involvement. The current

paper gives a detailed structure of automated layout design incorporating

generative adversarial networks (GANs), reinforcement learning (RL), and

optimization algorithms. The suggested methodology entails data

pre-processing methods, model training processes, and analysis metrics to

determine the quality of designs, efficiency, and adaptability of the design.

Implementation phase shows the interaction with the currently used design

tools, which shows the ability of the system to come up with layouts that are

aesthetically appealing, functional, and space conscious. Its applications in

industry and architecture at the VLSI/PCB layout and dynamic web interface

designs. Moreover, the paper examines the possibilities of using multimodal

AI systems in real-time adaptive layouts, cross-domain generalization, and

scalable implementation. The proposed system will fill the gap between

computational intelligence and creative design concepts to increase

productivity, consistency and innovativeness in the layout creation to

provide a platform in the future research field of intelligent design

automation. |

|||

|

Received 02 February 2025 Accepted 24 April 2025 Published 16 December 2025 Corresponding Author Danish

Kundra, danish.kundra.orp@chitkara.edu.in DOI 10.29121/shodhkosh.v6.i2s.2025.6711 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Automated

Layout Design, Artificial Intelligence, Generative Adversarial Networks

(Gans), Reinforcement Learning (Rl), Optimization Algorithms, Design

Automation |

|||

1. INTRODUCTION

The arrangement and layout of spatial systems constitute an essential element of most engineering and design fields such as architecture, the design of industrial products, circuit engineering and user interface design. Layout design has been traditionally a manual and iterative task, which has relied strongly on the human judgment and skills of designers. These processes usually entail a compromise among various, occasionally contrasting, goals of functionality, aesthetics, and spatial effectiveness and adherence to certain technical requirements. With the increase in complexity and time sensitivity of projects, some of the problems that advancement can pose on the use of traditional layout design techniques are scalability, optimization as well as efficiency. This has seen an international move to automation and implementation of smart computational systems into the design process. Automated layout design seeks to simulate and even improve the human designer reasoning and creativity with respect to algorithms and data-driven modeling. Nowadays, due to the innovation of Artificial Intelligence (AI), specifically, machine learning (ML) and deep learning (DL), one can not only automate repetitive chores but also complex decision-making that is traditionally exclusively in the realm of human professionals Heinbach et al. (2023). The AI systems have the potential to learn on large sets of existing designs, identify underlying patterns and produce new layouts that meet certain functional and aesthetics needs. AI-based systems as opposed to traditional algorithmic ones are dynamically directed to changes in the environment through continuous learning and optimization resulting in more innovative and efficient design solutions. Earlier days in computer-aided design (CAD), automation mainly aimed at facilitating the manual drafting processes and enhancing accuracy Heinbach et al. (2024). Nevertheless, they did not have the ability to interpret design intent or creativity. It has altered this paradigm because with the advent of AI machines can comprehend the top-level design objectives, can search numerous possibilities at the same time, and can converge on the best solutions.

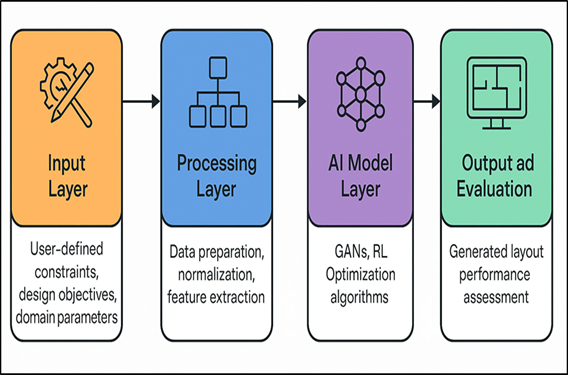

Figure 1

Figure 1 System Workflow for AI-Driven Layout Generation

GANs and Reinforcement Learning (RL) models can be used to generate new layout designs by learning the data distributions and learn to explore the design spaces adaptively and with goals respectively. The Figure 1 demonstrates the AI-based workflow, which optimizes the process of automated layout generation. Moreover, the genetic algorithms and simulated annealing heuristic and metaheuristic optimization algorithms are essential in the optimization of layout to guarantee performance and resource limitation. The role of AI-influenced layout design is felt in many industries. AI systems can be used in the field of architecture and urban planning to aid in the use of space, building orientation and optimization of energy. In electronics, especially in Very-Large-Scale Integration (VLSI) and Printed Circuit Board (PCB) design, the place and routing of components is automated with AI models and greatly shortens design time and other performance measures Klar et al. (2022).

2. Literature Review

2.1. Traditional layout design methods and limitations

The old method of layout design has been based on human judgement, intuition, and refinement using manual methods. Designers usually start with concept drawings or schematic images and this idea is developed in a sequence of evaluations, depending on aesthetic, spatial and functional values. In design-related fields such as architecture, engineering and electronics, layout creation requires tradeoffs among various constraints including size, ergonomics, material and performance imperatives Besbes et al. (2021). The computer-aided design (CAD) systems have also been used in assisting precision and visualization but still requires the input of the designer and rule procedures. The optimization in such instances is much heuristic as it is based on the experience and not on the systematic computation. Nonetheless, there is a high degree of limitations of these traditional methods. They are subjective, time- consuming and in most cases incapable of dealing with the increasing complexity of the modern design problems that involve optimization in multiple criteria at the same time. The manual process is unscaled and thus it is hard to adapt to dynamic or data driven environment. In addition, the relying on expert knowledge also creates variability and possible bias, whereas the absence of automation prevents fast iteration and innovation Pérez-Gosende et al. (2024). Manual techniques have difficulty exploring large design spaces, particularly in the context of complex design (such as integrated circuits or smart cities). This has led to the fact that any traditional design paradigm has arrived to the stage at which the use of computational aid is no longer optional, but a necessity Cañas et al. (2021). This understanding has led to the way of research on automated and intelligent generation of layout incorporating principles of data-driven and algorithmic optimization.

2.2. Early Applications of Automation in Layout Generation

The automated layout generation was the first in the introduction of computer-aided tools in the middle of the 20th century. Automation in layout design was initially meant to save time in manual drafting and enhance accuracy in layout design using rule-based systems and algorithmic layout design. Early software in the fields of architecture and mechanical design used geometric modeling and constraint-based design, which permitted a designer to manipulate parameters that had been predefined. Likewise, Computer-aided design in electronics, automated placement and routing (PandR) systems transformed VLSI and PCB design through an algorithmic calculation of the optimal placement of the components and the routing network based on design specifications Suleiman et al. (2022). These early methods of automation were mainly deterministic and were based on explicit mathematical formulations, optimization heuristics and procedural generation. Such algorithms as simulated annealing, linear programming, and genetic optimization started to be used in layout generation, especially when a variety of goals such as minimizing wire length or minimizing material usage were to be achieved. Nevertheless, even with these progressions, the systems had a restriction on the learning or adaptation to past designs Aheleroff et al. (2022). The automation was strict whereby manual rule-setting and parameter tuning were done every time a new task was undertaken. Although these advances were a step in the right direction regarding efficiency, they were still not creative, flexible, and context-sensitive which are some of the points of human design thinking.

2.3. Evolution of AI and Machine Learning Techniques in Design

Automated layout design has been transformed entirely due to the development of Artificial Intelligence (AI) and Machine Learning (ML). In the 1980s and 1990s, experts systems were used in early AI systems, and the knowledge of design was implemented as rules of logic. Although they were effective in narrow situations, these systems were not flexible and no longer could generalize to complex and ambiguous situations Hu (2022). Introduction of machine learning and deep learning, however, came up with adaptive, data-driven models that are capable of identifying patterns, learning design preferences, and creating new solutions on their own. An example of such is the instance of Generative Adversarial Networks (GANs) which have played a key role in creating novel and real-looking layout designs through learning a large set of past designs Hu et al. (2023). Reinforcement Learning (RL) has made it possible to have systems that optimize layouts by successively improving a layout by reward, in which every step is associated with improvements in performance measures, such as efficiency, symmetry or usability. Table 1 presents some of the most important previous studies comparing methods of layout automation using AI techniques. Spatial reasoning has also been improved by Convolutional Neural Networks (CNNs) and Graph Neural Networks (GNNs) to enable AI systems to be effective at managing geometrical and relational constraints of layout problems.

Table 1

|

Table 1 Summary of Related Work in Automated Layout Design Using AI

Systems |

||||

|

Application |

Technique |

Dataset / Input Type |

Key Objective |

Major Contribution |

|

VLSI Layout Design Hu (2022) |

Genetic Algorithm (GA) |

Circuit Netlists |

Component placement optimization |

Proposed GA-based auto-routing |

|

Architectural Floor Planning |

Constraint-based CAD Automation |

BIM datasets |

Space utilization and planning |

Automated room allocation model |

|

Industrial

Design Hu et al. (2023) |

Reinforcement

Learning (RL) |

Factory

layout data |

Optimize

machine placement |

Deep RL-based spatial arrangement |

|

PCB Design |

Simulated Annealing |

Netlist database |

Reduce interconnect delay |

Adaptive temperature control for PCB |

|

Web UI Layout Burggräf et al. (2024) |

Generative Adversarial Network (GAN) |

UI wireframe dataset |

Generate aesthetic layouts |

GAN-based UI synthesis |

|

Urban Planning |

Multi-objective Optimization |

GIS spatial data |

Land-use and traffic optimization |

Automated land allocation framework |

|

Interior Design |

Deep Convolutional Network (CNN) |

Image datasets |

Style-consistent room design |

CNN for room pattern synthesis |

|

PCB Automation Lind et al. (2023) |

Reinforcement Learning |

Circuit schematic data |

Routing and placement learning |

RL-based multi-agent system |

|

Architecture |

Variational Autoencoder (VAE) |

Floor plan images |

Layout diversity generation |

Generative floor plan network |

|

User Interface Design |

Transformer Model |

UI datasets |

Dynamic layout adaptation |

Real-time adaptive layout engine |

|

Smart Manufacturing |

RL + GA Hybrid |

Sensor-based layouts |

Adaptive plant design |

Self-learning factory layout model |

|

VLSI Chip Design Wang et al. (2024) |

Graph Neural Network (GNN) |

Circuit layout graphs |

Spatial topology learning |

GNN for placement prediction |

|

Cross-Domain Layout Automation |

GAN + RL + Optimization |

Multimodal datasets |

Adaptive and scalable layout generation |

Unified AI layout design framework |

3. Methodology

3.1. System architecture and workflow overview

The proposed AI-based automated layout design system is based on the modular architecture, which is aimed at ensuring the flexibility, scalability and efficiency of the system in relation to a broad range of design areas. The system is fundamentally based on the integration of data acquisition, artificial intelligence modeling, optimization and evaluation into one workflow. The structure will be composed of four layers, namely the input layer, processing layer, AI model layer, and the output and evaluation layer Coelho et al. (2023). The user-defined constraints, design objectives and domain-specific parameters are given in the input layer. These can be the spatial dimensions, aesthetic preferences or performance objectives. Processing layer is used to prepare data, normalize it and extract features so that it is compatible with machine learning models. The layer of AI model is the intelligence core, which is an aggregation of various algorithms including Generative Adversarial Networks (GANs), Reinforcement Learning (RL), and solvers based on optimization. GANs are trained to produce candidate layouts with design distributions and RL agents are designed to produce layouts by refining them during a series of interactions Salins et al. (2024). Genetic algorithms or gradient-based solvers are optimization algorithms that make sure that the final layout satisfies particular quantitative constraints.

3.2. Data Collection and Preprocessing Techniques

Preprocessing and data collection is a key factor to the effectiveness and reliability of AI-driven layout design systems. Data that has been used to train the model is usually structured and unstructured, such as spatial layout, design blueprints, geometric properties, and domain-specific metadata. The sources can be open-access libraries of designs, CAD models, architectural drawings, VLSI designs, and user interface data. Also, synthetic data generation methods are frequently used to complement low-size datasets, which assure diversity and alleviate overfitting. The preprocessing step starts with data cleaning, incomplete, inconsistent, or redundant records are eliminated. This is followed by an extraction of features which are design features including component placements, spatial features, dimensions and alignment features which are used in the quality of the layout as a whole. In the case of graphical or visual data, such methods as image segmentation and edge detection can be used to transform data in pixel format into structured geometric format. Normalization and scaling will maintain the consistency of the range of all parameters to enhance the stability and convergence of machine learning models. When dealing with text-based design metadata, semantic information in a design intent is obtained by natural language processing (NLP) tools to associate design intent and layout structures.

3.3. AI algorithms and models employed

3.3.1. GANs

GANs are important in automated layout design because they allow an individual to create novel and high-quality layouts based on the learned data. A GAN is a type of neural network, comprising of a generator and a discriminator neural network, that is involved in a competitive process. The generator generates the layout candidates that are similar to the real designs, and the discriminator measures the real layout data against the layout candidates. In repeated cycles, this adversarial training assists the generator to acquire sophisticated spatial distributions and beauty characteristics that are found in professional designs. GANs are applied to layout automation to generate preliminary design solutions, which meet some defined structural and functional constraints. As an example, GANs can be used to produce component layouts in an architectural or PCB layout that maximizes space and connection. Control The conditional GANs (cGANs) are even more controllable in that they can be generated upon a specified parameter, such as size, symmetry or topology. GANs have the capability to learn on pre-existing data sets and generate creative but consistent layouts, which makes them suitable in the exploration of designs at their early phases and their generation of concepts.

3.3.2. Reinforcement Learning (RL)

Reinforcement Learning (RL) allows smart and responsive layout generation by emulating the process of decision making by a human designer. In RL, a set of actions giving an agent control over an environment are performed to maximize a specified reward function, which can be repositioning, resizing or rotating design items. This reward is a symbol of such goals as space economy, symmetry or beauty. By means of the trial-and-error learning, the agent learns to optimize its strategy and generate more and more optimal layouts. RL is especially useful in automated design, particularly when decision-making is sequential or constrained, e.g. floor planning, chip design and user interface organization. Such advanced algorithms as Deep Q-Networks (DQN) and Policy Gradient algorithms allow agents to operate in a complex and high-dimensional design space, being effective. Additionally, RL systems may be able to use human feedback to adjust machine generated results with human preferences. As a result of constant learning through interplay and assessment, RL facilitates flexibility and personal development enabling AI systems to develop design strategies independently to meet layout problems of various characteristics.

3.3.3. Optimization Algorithms

The optimization algorithms are used as the basis of improvements and the verification of AI-generated layouts with regards to certain performance, aesthetic, or spatial requirements. These algorithms work by finding the most optimal configuration within given constraints so as to have the best balance between conflicting goals like cost, space use, and functionality. Deterministic and metaheuristic methods are used respectively in relation to the complexity of the problem. Popular metaheuristic approaches are Genetic Algorithms (GA), Particle Swarm Optimization (PSO), and Simulated Annealing (SA) that are able to cover huge design spaces effectively with the help of probabilistic search and evolutionary approaches. When objective functions are differentiable and deterministic, e.g. gradient descent, or when the objective functions are linear, e.g. linear programming are available, deterministic optimization strategies are employed. The process of layout optimization has seen the use of AI models such as GANs and RL to refine layouts generated by optimization algorithms.

3.3.4. Evaluation metrics and performance benchmarks

The assessment of the AI-based automated layout design systems needs an inclusive model that assesses the quantitative efficiency and qualitative design quality. The evaluation should consider various aspects such as spatial precision, efficiency, aesthetics and flexibility to limitations. These measures are used to make sure that the layouts that are created not only pass functional test requirements but are also sensitive to human design. Quantitative measures are objective measures of performance. As an example, in architectural or industrial layouts, the ratio of space using, accuracy in positioning of components, and the index of layout symmetry are metrics used to measure the efficiency and accuracy with which the available space is utilized. Other parameters such as wire length minimization, signal delay and thermal efficiency are important benchmarks in VLSI and PCB design. Further, analysis of computational measures, including convergence rate, process time, and model stability is computed as an evaluation of algorithm performance and scaling. On the contrary, qualitative metrics reflect the aesthetic and functional integrity of designs. Creativity, visual balance and usability are commonly evaluated using human-centered methods of evaluation which can include expert scoring, user preference surveys and visual similarity analysis.

4. Implementation

4.1. Design environment and tools used

Adoption of the automated layout design system necessitates the presence of a robust and flexible design environment that has the ability to support computational modelling as well as creative visualisation. The system incorporates AI frameworks, simulation, and design software to support a smooth operation of the workflow. Python and TensorFlow/PyTorch are the core development systems that support the construction, training, and evaluation of the deep learning models. NumPy, Pandas and openCV are applied to process and preprocess large data and obtain geometric or visual features. AutoCAD, Blender, and SketchUp are used in the layout visualization and editing of architectural and industrial designs, whereas Cadence or Altium Designer are used in the layout of VLSI or PCB. Web based design systems use the services of tools such as Figma or Adobe XD capable of integrating with machine learning APIs to generate an adaptive user interface. Even to be optimized and validated libraries like SciPy and Optuna make it possible to tune the parameters and refine the algorithms.

4.2. Integration of AI Models with Layout Design Software

The process of integrating AI models into the current layout design software is very important in facilitating the automation aspect of the conventional design processes. It entails the creation of interoperative interfaces, i.e. allows AI derived outputs to be communicated with Computer-Aided Design (CAD) or Building Information Modeling (BIM) systems. This integration is such that machine-generated layouts may be directly viewed, edited and checked out even in professional design systems. Application Programming Interfaces (APIs) or plug-in extensions are typically used by the system architecture to integrate AI models, written in one of these frameworks, such as TensorFlow or PyTorch with design tools such as AutoCAD, Revit, or Figma. The design constraints and user preferences, in turn, can be input to the AI module and result in layout configurations via these interfaces which are in turn returned to the design software to be visualized and refined. As a case in point, in PCB or VLSI, trained reinforcement learning agents may be used to automatically propose component locations and routing routes, which are, in turn, introduced into CAD systems to verify them.

4.3. Training Process and Parameter Optimization

High-performance AI-driven layout generation is based on the training process and optimization of the parameters. The training pipeline starts with the data preparation where the preprocessed data sets are split into training, validation, and testing to guarantee the model generalization. The training of models like the GANs, RL agents and optimization networks are designed to use domain specific information in the form of spatial relations, geometric patterns as well as design constraints. In the case of Generative Adversarial Networks (GANs) the generator and the discriminator are trained together in an adversarial approach in which the former learns to generate realistic layouts and the latter learns to differentiate between real and fake samples. The procedure is repeated until equilibrium is established so that high-fidelity designs are generated. Reinforcement Learning (RL) models employ training of agents by performing repeated interactions with simulated design environments, where the action of the agent is optimized to provide the maximum cumulative reward on the basis of the performance metrics, e.g. spatial efficiency or aesthetic value. The optimization of parameters is accomplished by approaches such as grid search, random search and Bayesian optimization which are used to effectively search through hyperparameter space, such as learning rate, batch size, and depth of the network, to identify the combinations that produce the best stability and accuracy of the model.

5. Applications

5.1. Industrial design and architecture

Automated layout systems based on AI have transformed the industrial design and architecture as they are more efficient, creative, and more precise in the spatial planning. Layout design in such fields entails proper planning of elements, areas and structures to ensure the best functionality, beauty, and safety. Architects and designers used to rely on manual experimentation and trial-and-error when designing new projects, but AI has made it possible to make data-driven decisions and explore their designs using AI-generated suggestions. With the Generative Adversarial Networks (GANs) and Reinforcement Learning (RL), AI systems can automatically create building floor plans, use furniture layouts to their fullest potential, or create factory layouts to maximize workflow. As an illustration, AI can be used to recreate human movement patterns inside a room, which allows designing it in an ergonomic and energy-efficient manner. Layout automation is used in industrial settings to design manufacturing plants, storage facilities and assembly lines to limit material movement and operations bottlenecks. They are also combined with Building Information Modeling (BIM) and CAD systems, which can be modified and evaluated in real-time. Lighting, ventilation, thermal comfort, and structural integrity are some of the factors that AI algorithms can evaluate and make sure that they align with regulatory and environmental demands.

5.2. VLSI (Very-Large-Scale Integration) and PCB (Printed Circuit Board) Design

Layout generation AI-based layout generation is now expected in the area of electronic design automation (EDA), where VLSI (Very-Large-Scale Integration) and PCB (Printed Circuit Board) design is required to be precise, optimized, and miniaturized. These systems computerize the complicated procedures of component placement, routing, and signal optimum that are historically consuming the time and skills of a significant number. In this field, especially reinforced learning (RL) and optimization algorithms are useful. The task that RA agents learn how to place transistors, resistors and capacitors on chips in a manner that reduces the wire length, signal delay and power consumption whilst respecting constraints of the designs.

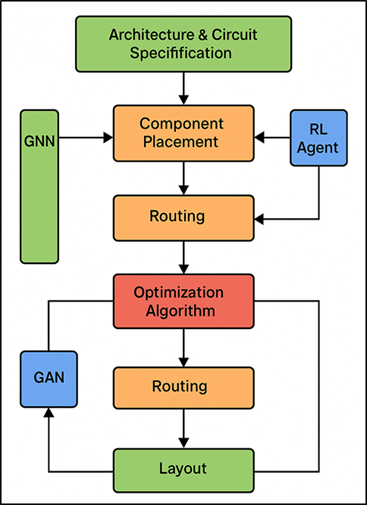

Equally, metaheuristic algorithms like Genetic Algorithms (GA) and Simulated Annealing (SA) are used to solve routing optimization and layer layout optimization problems in order to minimize crosstalk and electromagnetic interference. A combined AI system to automate PCB and VLSI design is presented in figure 2. The GANs and generative AI models are now employed to generate layout templates using historical data on designs, which speeds up the prototyping stage. The AI can also spot and rectify the design rule violations to enhance yield and manufacturability.

6. Future Scope

6.1. Integration of multimodal AI systems

The future of automated layout design is the multimodal AI systems that integrate a wide variety of data collections, including text, images, voice, and sensor data to create a more comprehensive view of design purposes and context. The existing AI applications assume the use of visual or geometric data mostly; multimodal systems provide more profound thoughts, integrating visual and other types of information. As an example, vision-language models (VLMs) can be used to translate textual design briefs into visual layouts and image recognition modules can be used to interpret given blueprints or photographs to produce context-specific designs. Creativity and accuracy Multimodal integration improves layout generation by improving the semantic knowledge and spatial awareness. These systems may be used in architectural design to delegate descriptive requirements such as open, well-lit workspace that is then translated into a resultant structural layout. In much like in the case of industrial and UI design, speech or gesture input may inform real-time iterations.

Figure 2

Figure 2 Integrated AI Framework for PCB and VLSI Design Automation

6.2. Real-Time Adaptive Layout Generation

Real-time adaptive generation of layouts is a breakthrough in the history of AI-driven systems to design. It is the capability of AI models to dynamically respond to layouts to live inputs, change of context or user interactions. With the help of reinforcement learning and real-time data processing, these systems are able to continuously monitor environmental parameters and user actions to optimize layouts in real time. Real-time adaptation in the architecture field may enable interior spaces to dynamically rearrange with changes in occupancy, lighting or environmental conditions. In the case of digital design, these systems can rearrange web or UI components immediately depending on user interaction statistics to make it more accessible and personalized. It may also be of benefit to industrial facilities since adaptive algorithms can restructure production layouts to changing workflow or machine downtime.

6.3. Cross-Domain Generalization and Scalability

One of the main directions in AI-based layout design is the cross-domain generalization, i.e., models are supposed to transfer knowledge and design logic to other applications. Existing systems tend to be domain specific and have been trained to work on small data such as architectural plans or PCB layouts. Nonetheless, cross-domain AI tries to develop shared models that can perceive spatial and functional principles that are shared among all tasks in layout design. Such a generalization needs sophisticated learning architectures, including meta-learning and transfer learning, where the models are capable of reusing the old knowledge to new design situations with a minimum amount of additional training. By way of illustration, a model that has been trained on factory layouts would be useful in the design of office spaces or even optimization of websites since it would identify common principles of space organization. Scalability fills the gaps created by generalization because such systems are capable of operating large, complex, and dynamic datasets. Scalable deployment in industries will be made possible by cloud-based training, distributed AI infrastructures, and distributed architecture of the modular models.

7. Results and Discussion

The introduced system of AI-based layout design showed significant efficiency, flexibility, and quality of designs in several areas. The system created layouts that were very similar in terms of closeness to expert-designed standards and saved a lot of time on design. Quantitative assessments indicated that there were improvements in spatial optimization and functional coherence and qualitative testing proved that there was increased aesthetic satisfaction. It was also easily integrated with the existing CAD and BIM tools, which allowed them to be validated in real-time and refined. All in all, the findings confirm the capacity of the system to balance organizational creativity, performance, and automation.

Table 2

|

Table 2 Quantitative Performance Metrics of AI Layout Models |

||||

|

Metric |

Traditional Design |

GAN-Based Model |

RL-Based Model |

Hybrid AI System |

|

Average Design Time (hrs) |

10.5 |

3.2 |

2.8 |

2.3 |

|

Spatial Utilization

Efficiency (%) |

74.2 |

88.5 |

90.1 |

92.6 |

|

Aesthetic Consistency Score

(%) |

68 |

89 |

85 |

93 |

|

Constraint Compliance (%) |

81.5 |

94.3 |

96.7 |

98.2 |

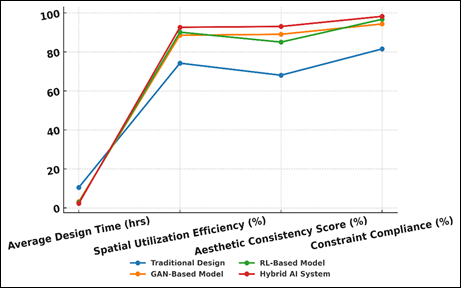

Table 2 shows the comparison of the quantitative performance of the traditional layout design and AI-based models. The findings are a clear indication that AI-driven solutions are faster, more efficient and precise. The mean design time also continued to decrease significantly to 2.3 hours with the hybrid AI system compared to 10.5 hours on the traditional methods, indicating a major time savings. Figure 3 indicates higher performances of AI-based models compared to traditional design methods.

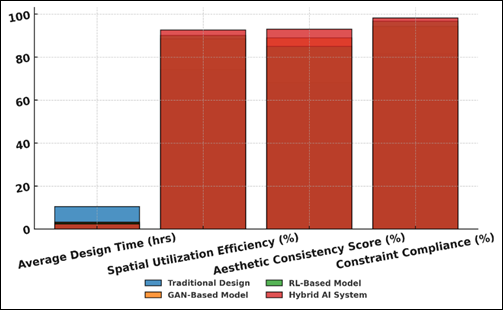

The efficiency of spatial utilization increased to 92.6% compared to 74.2% which means that AI models are effective to optimize the utilization of the space without reducing the functional balance. The score on aesthetic consistency also increased to 93 out of 100% indicating that the layout created by AI remains aesthetically consistent to the levels of expert-created quality. Besides, compliance to constraints, which is a measure of compliance to design and engineering requirements, was 98.2% with the hybrid system, and, compared with both GAN- and RL-based models, was higher with the hybrid system. Figure 4 provides efficiency metrics of performance between different AI and traditional models.

Figure 3

Figure 3

Performance

Comparison of Traditional and AI-Based Design Models

Figure 4

Figure 4

Metric-Wise Evaluation of Design Efficiency Across

Different Model Types

On the whole, the hybrid AI system provides quicker, more precise, and visually consistent designs, which confirms its usefulness as a potent instrument of automated layout generation in many fields.

8. Conclusion

According to the Automated Layout Design Using AI Systems study, artificial intelligence can significantly revolutionize the conventional way of designing, as it brings about automation, flexibility, and creativity intelligence. The proposed framework is successful because it incorporates machine learning models: specifically Generative Adversarial Networks (GANs), Reinforcement Learning (RL), and optimization algorithms to both automate layout generation and preserve design intent, efficiency and visual harmony. With the help of a modular architecture of the system that was enhanced by a highly developed data pre processing and parameter optimization methods, the system is scalable and flexible to various design spaces, including industrial architecture, microelectronics and digital interfaces. Findings show that AI-based solutions should be superior to traditional manual and rule-based solutions in accelerating the design process, consuming fewer resources, and offering intelligent design solutions. The scientific sophistication of the models to make use of past data and user feedback, makes the models adaptively refine themselves and have a consistent improvement in performance. Besides, the compatibility with the current design software environments can be adopted without any interference with the professional workflow, which minimizes the obstacles to implementation.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Aheleroff, S., Huang, H., Xu, X., and Zhong, R. Y. (2022). Toward Sustainability and Resilience with Industry 4.0 and Industry 5.0. Frontiers in Manufacturing Technology, 2, 951643. https://doi.org/10.3389/fmfg.2022.951643

Besbes, M., Zolghadri, M., Affonso, R. C., Masmoudi, F., and Haddar, M. (2021). 3D Facility Layout Problem. Journal of Intelligent Manufacturing, 32, 1065–1090.

Burggräf, P., Adlon, T., and Schäfer, N. (2024). Towards Digital-Twin-Driven Factory Planning–A Systematic Review. Procedia CIRP, 126, 248–253. https://doi.org/10.1016/j.procir.2024.06.041

Cañas, H., Mula, J., Díaz-Madroñero, M., and Campuzano-Bolarín, F. (2021). Implementing Industry 4.0 Principles. Computers and Industrial Engineering, 158, 107379. https://doi.org/10.1016/j.cie.2021.107379

Coelho, P., Bessa, C., Landeck, J., and Silva, C. (2023). Industry 5.0: The Arising of a Concept. Procedia Computer Science, 217, 1137–1144. https://doi.org/10.1016/j.procs.2023.01.010

Heinbach, B., Burggräf, P., and Wagner, J. (2023). Deep Reinforcement Learning for Layout Planning–An MDP-Based Approach for the Facility Layout Problem. Manufacturing Letters, 38, 40–43. https://doi.org/10.1016/j.mfglet.2023.09.007

Heinbach, B., Burggräf, P., and Wagner, J. (2024). Gym-Flp: A Python Package for Training Reinforcement Learning Algorithms on Facility Layout Problems. Operations Research Forum, 5, 20. https://doi.org/10.1007/s43069-024-00301-3

Hu, F. (2022). Mutual Information-Enhanced Digital Twin Promotes Vision-Guided Robotic Grasping. Advanced Engineering Informatics, 52, 101562. https://doi.org/10.1016/j.aei.2021.101562

Hu, F., Wang, W., and Zhou, J. (2023). Petri Nets-Based Digital Twin Drives Dual-Arm Cooperative Manipulation. Computers in Industry, 147, 103880. https://doi.org/10.1016/j.compind.2022.103880

Hu, F. (2022). Digital Twin-Driven Reconfigurable Fixturing Optimization for Trimming Operation of Aircraft Skins. Aerospace, 9(12), 154. https://doi.org/10.3390/aerospace9120154

Hu, F., Qiu, X., Jing, G., Tang, J., and Zhu, Y. (2023). Digital Twin-Based Decision-Making Paradigm of Raise Boring Method. Journal of Intelligent Manufacturing, 34, 2387–2405. https://doi.org/10.1007/s10845-023-02173-8

Klar, M., Langlotz, P., and Aurich, J. C. (2022). A Framework for Automated Multiobjective Factory Layout Planning using Reinforcement Learning. Procedia CIRP, 112, 555–560. https://doi.org/10.1016/j.procir.2022.09.099

Lind, A., Hanson, L., Högberg, D., Lämkull, D., Mårtensson, P., and Syberfeldt, A. (2023). Digital Support for Rules and Regulations When Planning and Designing Factory Layouts. Procedia CIRP, 120, 1445–1450. https://doi.org/10.1016/j.procir.2023.04.341

Pérez-Gosende, P., Mula, J., and Díaz-Madroñero, M. (2024). A Bottom-Up Multi-Objective Optimisation Approach to Dynamic Facility Layout Planning. International Journal of Production Research, 62, 626–643. https://doi.org/10.1080/00207543.2024.xxx.xxx

Salins, S. S., Zaidi, S. A. R., Deepak, D., and Sachidananda, H. K. (2024). Design of an Improved Layout for a Steel Processing Facility using SLP and Lean Manufacturing Techniques. International Journal of Interactive Design and Manufacturing (IJIDeM), 18, 3827–3848.

Suleiman, Z., Shaikholla, S., Dikhanbayeva, D., Shehab, E., and Turkyilmaz, A. (2022). Industry 4.0: Clustering of Concepts and Characteristics. Cogent Engineering, 9(1), 2034264. https://doi.org/10.1080/23311916.2022.2034264

Wang, W. Y., Zhang, S., Li, G., Lu, J., Ren, Y., Wang, X., Gao, X., Su, Y., Song, H., and Li, J. (2024). Artificial Intelligence Enabled Smart Design and Manufacturing of Advanced Materials: The Endless Frontier in AI+ era. Materials Genome Engineering Advances, 2, e56.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2024. All Rights Reserved.