ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

Smart Print Management Using Predictive Analytics

Dr. Soumitra Das 1![]() , Rutu Bhatt 2

, Rutu Bhatt 2![]()

![]() ,

Madhur Grover 3

,

Madhur Grover 3![]()

![]() , Dr. Charu Wadhwa 4

, Dr. Charu Wadhwa 4![]()

![]() ,

Aseem Aneja 5

,

Aseem Aneja 5![]()

![]() ,

Shikha Gupta

,

Shikha Gupta ![]()

1 Associate

Professor, Department of Computer Engineering, Indira College of Engineering

and Management, Pune, India

2 Assistant

Professor, Department of Interior Design, Parul Institute of Design, Parul

University, Vadodara, Gujarat, India

3 Chitkara Centre for Research and Development, Chitkara University,

Himachal Pradesh, Solan, 174103, India

4 Associate Professor, Department of Management, ARKA JAIN University

Jamshedpur, Jharkhand, India

5 Centre of Research Impact and Outcome, Chitkara University, Rajpura-

140417, Punjab, India

6 Assistant Professor, School of Business Management, Noida International

University 203201, India

|

|

ABSTRACT |

||

|

This study is

a proposal of a smart, foresight analytics-based Smart Print Management model

that can maximize efficiency, reliability, and sustainability of enterprise

print settings. The traditional print management systems are based on

reactive operations and thus they have recurring device failures, consumable

is used inefficiently and there is little visibility of the print behaviors.

In order to seal these cracks, the suggested framework incorporates

IoT-enabled telemetry, machine-learning-enabled forecasting, predictive

maintenance, and anomaly detection in order to make the print management an

interactive and automatic decision-making infrastructure. The system gathers

multi-modal data on heterogeneous printer fleets like print volumes, device

health metrics and job-level logs and processes them in an effective data

acquisition and preprocessing pipeline. LMST and print volume predictive

models, random forest and XGBoost predictive models

for failure prediction, autoencoders models to predict anomalies are used to

analyze operational trends and predict future status. The experimental use of

those models proves their ability to predict workload changes, reveal the

earliest indicators of a device malfunctioning, and causes of abnormal

printing behavior, which allows the routing of jobs automatically, routine

maintenance, and notifications about security vulnerabilities. The results

indicate that there were significant gains regarding continuity of

operations, cost reduction, optimization of consumables, and performance in

terms of sustainability. The paper concludes that predictive analytics will

offer a substantial degree of responsiveness and resiliency of the print

management infrastructure. The lines of the future research involve the study

of federated learning, reinforcement learning coordination, and digital twin

simulation to develop automation, scalability, and privacy of smart print

ecosystems further |

|||

|

Received 27 January 2025 Accepted 18 April 2025 Published 16 December 2025 Corresponding Author Dr.

Soumitra Das, soumitra.das@indiraicem.ac.in DOI 10.29121/shodhkosh.v6.i2s.2025.6710 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Predictive

Analytics, Smart Print Management, Iot-Enabled Printers, Print Demand

Forecasting, Predictive Maintenance, Anomaly Detection, Machine Learning,

Operational Optimization; Enterprise Print Ecosystems, Data-Driven

Decision-Making |

|||

1. INTRODUCTION

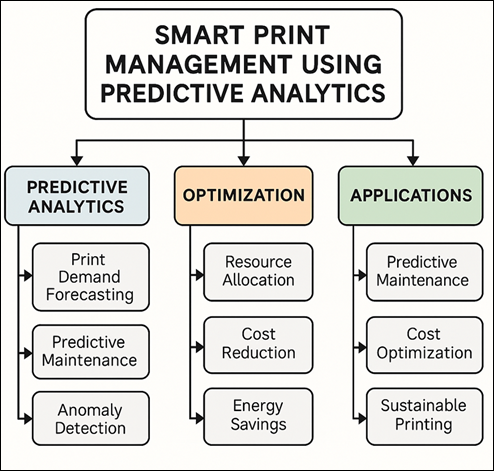

A new solution has been introduced to the critical technology that is being applied in the contemporary organizational setting, where efficiency, sustainability, and cost optimization are the main priorities. Enterprises that have continued to produce large volumes of print jobs like administrative documents, operational forms among others tend to be inefficient in conventional print management systems, which usually fail to mitigate factors like waste of resources, unwanted downtime, and irregular distribution of loads among devices Advisera. (2017). These disadvantages have a direct effect on the productivity of operation and environmental sustainability. As the volume of data-driven technologies has increased exponentially, predictive analytics has emerged as a strong enabler that allows print ecosystems to change their reactive, manual-driven systems into proactive and intelligent systems. Predictive analytics is a statistical modeling, machine learning, and real-time monitoring system that is used to predict print demand, predict equipment failures, and optimize resource allocation. In a smart print system, the historical print logs, user behaviors, toner consumption trends, and device health signals could be analyzed to enable organizations to anticipate the operation requirements in advance before problems occur as depicted in Figure 1. This allows making a transition to predictive maintenance, minimizing unexpected downtimes of printers, minimizing the number of service interruptions, and improving the reliability of print infrastructure Kryvinska (2012). Future print volumes, schedules of toner depletes, and unusual usage patterns, which can signal misuse or cyber threat can be accurately predicted using predictive models, including ARIMA, LSTM, and Random Forest.

Figure 1

|

Figure

1 Block Diagram for Taxonomy Diagram, Evolution

Timeline |

The rationale of applying predictive analytics in print management lies in the rising levels of cost disparagement and sustainability obligations in industries. Print operations normally incur high overhead costs (maintenance, consumables, energy usage, etc., device replacement). Using predictive knowledge, organizations can automate policy making like the smart policies like routing print jobs to the most efficient printer, scheduling of maintenance at an optimal time or access control by user behavior Molnár et al. (2014). This smart coordination results in quantifiable cost, waste and energy savings, and coordination of print activity with the wider scope of digital changes. Besides, predictive systems facilitate responsible printing habits, where trends in user behavior can be detected and acted on accordingly e.g. print quotas, alerts or eco-friendly suggestions. When used in large-scale deployment, predictive analytics can be integrated with printers that are IoT-enabled and cloud-based management systems to provide real-time monitoring of distributed networks Amendola et al. (2018). Modern printers have sensors which give a constant feed back on component wear, temperature variations, ink levels, error patterns etc. In addition, insights can help drive strategic planning and assist organizations in determining when to upgrade devices, shift workloads, introduce new policies, or reorganize print workflows with the use of data-driven insights. Smart print management with the help of predictive analytics has its own peculiarities, despite its potential to transform the industry. The problem of data privacy issues, incompatibility of other heterogeneous printers, necessity of scalable computing platforms can be taken into account when designing a system. Moreover, the quality of predictive models strongly relies on the quality of data and the strong preprocessing methods Vaidya et al. (2018). However, the development of cloud computing, edge analytics, and hybrid AI systems does not stop, and the possibility to use predictive print systems on a large scale is becoming a reality.

2. Literature Review

The development of print management systems has been influenced by the improvement of information technology, automation, and data analytics. The conventional print management system was based on the first-mover policies, hand-crafted control, and post-hoc repair. These outdated systems had worked well in low volume printing systems but failed to work as organizations grew and printing requirements diversified Vogel-Heuser and Hess (2016). Preliminary studies on optimization of prints involved minimizing waste of paper and user control in form of basic quota systems and print monitoring software. Nevertheless, these systems were not intelligent, flexible and predictive which made their performance in dynamic enterprise settings restricted. As more networked printers became available and enterprise print fleets began to develop, more elaborate print management solutions became available. These systems included centralized monitoring board, user verification and usage. Among contributions during this time was job-level accounting, pull-printing, and rule-based optimization which were used to evenly distribute workloads and print policies. Research also emphasized that central management enhanced security and minimized the number of unauthorized accesses to printed documents. Nevertheless, rule based systems were fixed and not capable of dynamically reacting to changes in demands of prints, health of a device or consumable levels in real time Tomiyama et al. (2019).

Table 1

|

Table 1 Evolution of Print Management

Approaches |

||||

|

Era / Approach |

Key Characteristics |

Strengths |

Limitations |

Representative Studies |

|

Traditional (Pre-IoT)

Kong et al.

(2020) |

Manual tracking, rule-based policies,

basic quota management |

Simple, low-cost, easy to deploy |

No predictive capabilities; reactive

maintenance; high inefficiency |

Early print quota systems; basic cost

tracking tools |

|

Centralized Print Management Garcia Plaza

et al. (2018) |

Networked printers, job-level

accounting, user authentication |

Improved security; central dashboard;

reduced unauthorized printing |

Static rules; limited real-time

analysis; no forecasting |

Studies on enterprise print control

& audit systems |

|

IoT-Enabled Print Environment Wang et al.

(2018) |

Sensor-enabled printers, telemetry data

(temperature, toner, job logs) |

Real-time monitoring; automated alerts;

better maintenance scheduling |

Still reactive; limited predictive

insight; data integration challenges |

Research on IoT-based printer fault

detection |

|

Predictive Analytics + ML Era Lu et al.

(2023) |

Forecasting, predictive maintenance,

anomaly detection |

High accuracy predictions; optimized

resource allocation; cost savings |

Requires quality data; scalability

issues; model complexity |

ARIMA, LSTM, Random Forest, SVM-based

print analytics frameworks |

The printing infrastructure was also a significant development in the area with the introduction of Internet of Things features. The new generation of printers with sensors started producing huge volumes of telemetry data, which falls into the following categories: temperature levels, device health history, print job history, toner use profile and component wear history. Work on IoT-based printers investigated the possibility to use this information to enhance the efficiency of operations and automate the process of detecting a fault Zhang et al. (2022). Some of the studies showed that the integration of IoT lowered the downtime since it allowed identifying frequent problems like paper jam, cartridge malfunction, and overheating at an early stage. Nevertheless, even with the improvement of monitoring, IoT continued to be used in most systems to response to maintenance issues, but not to use data insights to predict outcomes.

Table 2

|

Table 2 Machine Learning Techniques

Used in Smart Print Management |

||||

|

ML Technique |

Typical Use Case |

Dataset Requirements |

Advantages |

Limitations |

|

ARIMA / Prophet Gim et al.

(2023) |

Print volume forecasting |

Time-stamped print logs |

Simple, interpretable models |

Struggles with non-linear patterns |

|

LSTM / GRU Sjödin et al. (2018) |

Long-term print behavior

prediction |

Large historical datasets |

Captures complex temporal dependencies |

High training cost; needs GPU |

|

Random Forest / XGBoost

Shin (2019) |

Predictive maintenance, toner usage

prediction |

Sensor + usage data |

High accuracy, handles mixed features |

Moderate interpretability |

|

SVM / Logistic Regression Martínez-Mireles

et al. (2025) |

Classifying print job types, anomaly

detection |

Structured print logs |

Good for smaller datasets |

Limited scalability |

|

K-Means / DBSCAN Humbert et al. (2024) |

User behavior

clustering, anomaly detection |

Unlabeled print data |

Fast, effective for pattern discovery |

Sensitive to noise, tuning needed |

The predictive analytics and machine learning play a transformative role in optimizing print operations as highlighted in the recent literature. Predicting print workloads using time-series forecasting models like ARIMA and Prophet have been utilized by researchers to allow dynamic resource allocation in organizations. More sophisticated models such as LSTM based deep learning networks were applied to predict long term dependencies of print behavior and have given quite accurate print volume prediction. Research has also investigated supervised techniques of learning such as the Random Forest, XGBoost and Support Vector Machines in predictive maintenance in printer fleets.

Table 3

|

Table 3 Comparison of Traditional vs

Smart Predictive Print Systems |

||

|

Feature |

Traditional Systems |

Predictive Smart Systems |

|

Monitoring |

Manual or static dashboard |

Real-time IoT telemetry |

|

Maintenance |

Reactive |

Predictive and scheduled |

|

Print Routing |

Static rules |

ML-based dynamic routing |

|

Cost Efficiency |

Low to moderate |

High due to optimization |

|

User Behavior

Insight |

Limited |

Analytics-based profiling |

|

Sustainability |

Not considered |

Actively optimized |

The other research direction that is developing is anomaly detection in print systems. A spike in print volume that is unusual as well as attempts to enter the system without authorization and unusual patterns of behavior can be signs of security threats or abusive use. Outliers and protection of print infrastructure have been detected using machine learning models, especially isolation forests and clustering algorithms. Literature also points out the significance of print behavior analytics, in which user data is monitored on an individual user level to find areas of inefficiencies, impose restrictions, and promote printing behavior that is eco-friendly. Along with the predictive methods, there are also studies on the best strategies of print routing and load balancing. They use optimization algorithms to allocate the print jobs in accordance to the availability of devices, cost, energy consumption and estimated workload. It has been demonstrated that hybrid systems that combine predictive analytics and optimization models can be effective in reducing delays, lowering maintenance charges and enhancing the overall performance of the print fleet. Although the current literature offers useful information on the topic of IoT integration, machine learning-based models, and routing optimization, there are still considerable gaps. A lot of them work on small-scale settings and cannot prove their effectiveness at big businesses. There are also interoperability issues because printers and proprietary data formats and incompatible management protocols are heterogenous. Another significant issue is the security of data since print logs can hold sensitive information about the organization. In addition, there is scanty literature on the hybrid cloud-edge analytics frameworks integrating local real-time processing and centralized long-term prediction framework.

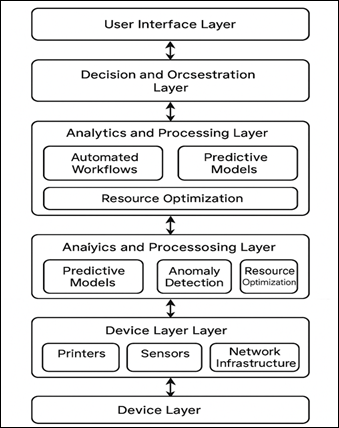

3. System Architecture for Smart Print Management Using Predictive Analytics

The use of a strong system architecture is required to facilitate the change to the traditional, reactive print environment to the intelligent, analytics-driven print ecosystem. The Smart Print Management Architecture suggested combines IoT-based networks of printers, real-time monitoring, predictive models, and automation of decisions to ensure the optimization of resource utilization, decrease the downtime, and increase the reliability of the operations. The architecture is implemented as a multi-layered system with every layer having a particular role to play in implementation of the end-to-end intelligent print management. The Device Layer lies at the center of the architecture, and it consists of a network of printers that are interconnected, have sensors, and are capable of communication. Such gadgets produce the telemetry data, i.e.: toner and ink readings, page printing, temperature and paper jam alarms, print job information, and wear data on the component parts. Contemporary enterprise printers are SNMP or REST API-enabled or use the MQTT-based message exchanges to communicate data to and from the printers. The non-homogenous character of printer models is resolved with the help of protocol adapters standardizing data format. Interoperability of devices at this layer is the basis of ensuring reliability and large scale monitoring as in figure 2. The Data Acquisition Layer manages the real-time gathering, mixture and pre-processing of data of dispersed print devices. This layer used IoT gateways, edge nodes or cloud ingestion pipelines e.g. Apache Kafka or Azure IoT Hub in order to provide a data flow that is continuous and fault-tolerant. This layer performs data cleaning, feature extraction, synchronization of timestamps and anomaly filtering to provide the high quality inputs to the downstream analytics. Systems that have latency-sensitive applications like immediate fault detection edge analytics nodes have preliminary analysis to reduce reliance on cloud servers and enhance responsiveness.

Figure 2

|

Figure

2 Smart Print Management System Architecture Diagram |

The intelligence of the architecture is a layer known as the Analytics and Processing Layer. In this case, the system uses predictive modeling to predict the amount of print required, analyze device condition, anticipate toner wastage, identify anomalies and efficiently assign resources. Print volume prediction is performed with time-series forecasting models (ARIMA, LSTM), that provide the opportunity to dynamically allocate the workload among printers. These predictive maintenance models (Random Forest, XGBoost, SVM) are used to predict failures or component degradation, and these problems are anticipated before they disrupt operations. Anomaly detection models find abnormal activity in printing that can be viewed as a security risk, abuse, or inefficiency in the operations. The reinforcement learning can also be added to this layer to maximize real-time decision policies, which increases long-term efficiency and sustainability. This layer serves as the brain of the system and coordinates automated processes like load balancing, maintenance schedules, toner order, job redirection and user-level interventions. Rules engine or intent-based policy module is a type of module that interprets the output of the model and implements system-wide printing policies. To illustrate the example, in case, the predictive model recognizes an impending toner depletion a system automatically initiates a replenishment request or reroutes print jobs to the equipment that is in close proximity. On the same note, in cases where workload forecasting indicates that there will be spikes, the system will also reassign the print jobs in order to ensure the best performance and prevent the bottlenecks. The last layer, the User Interface Layer, offers the administrators, IT managers, sustainability officers and end-users with dashboards and visual analytics. These dashboards show the health of the devices, predictive warnings, consumption patterns, print volume predictions and orchestration layer decisions. The visual insights do not only facilitate operational decision making but will also enable transparency and accountability among the users. The eco-score modeling, print quota monitoring, and per-department analytics are some of the features that promote responsible printing habits. This is a multi-layer system architecture that is scalable, flexible, and automated intelligently in the print environments. The modular structure enables it to easily interoperate with the existing enterprise IT systems, cloud computing, and security systems. The joint capabilities of the IoT sensing, machine learning, and automated decision-making create a comprehensive strategy of operating the print infrastructures in the most efficient and human-minimal way.

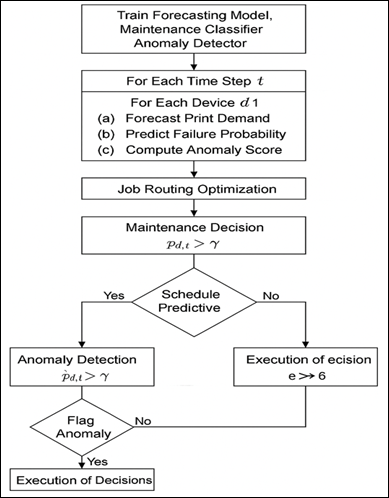

4. Proposed System Algorithm

The predictive analytics of smart print management heavily depend on quality, constant and useful data that is accumulated in a heterogeneous printer fleet. It contains how the system obtains, processes, purifies and transforms raw device and operational data into structured data forms that can be used to predict, identify anomalies and predictive maintenance as illustrated in n Figure 3. It is the foundation of the whole structure because the further analytics modules will be based on the information that will be reliable and representative.

Step 1: The algorithm starts with the step of algorithmic initialisation where three fundamental models are trained, namely, demand forecasting model, predictive maintenance classifier, anomaly detection autoencoder, using past print logs, device telemetry data, user activity features, and maintenance logs. This training phase also reflects the temporal patterns, signature of failures and normal operation patterns that each model should contain to make intelligent decisions.

![]()

![]()

![]()

![]()

Step 2: Every time step ![]() the algorithm is executed, then each device (

d ) in print fleet is processed. In each device, the first sub-step (2a) is

predicting future print demand with the help of the trained model

the algorithm is executed, then each device (

d ) in print fleet is processed. In each device, the first sub-step (2a) is

predicting future print demand with the help of the trained model ![]() The

model will be used to predict the demand in the near future in order to enable

the system to predict spikes of the workload or underutilization. In sub-step

the predictive maintenance classifier analyses the risk of failure within a

specified future window. It gives an estimated probability of failure sd,t= 2, which is estimated based on readings of sensors,

health indicators of the device, and past experiences of failures. Sub-step

entails calculation of an anomaly score entailed by reconstruction error of the

autoencoder.

The

model will be used to predict the demand in the near future in order to enable

the system to predict spikes of the workload or underutilization. In sub-step

the predictive maintenance classifier analyses the risk of failure within a

specified future window. It gives an estimated probability of failure sd,t= 2, which is estimated based on readings of sensors,

health indicators of the device, and past experiences of failures. Sub-step

entails calculation of an anomaly score entailed by reconstruction error of the

autoencoder.

Forecasting Model (Print Volume Prediction) ![]()

Step 3: The system is used to provide load balancing, reduce delays, and optimize use of resources without violating device capacities and service-level constraints through the inclusion of predicted workloads.

Step 4: Predictive maintenance decision is made based on the predicted probability of failure of an individual device using the algorithm. When the projected risk is above a preset threshold the system automatically sets up a maintenance time frame on said device.

Step 5: The algorithm will then deal with security and operational anomalies. In case the anomaly score calculated in Step 2c exceeds a threshold, the system considers that the device or job is anomalous. The detection mechanism provides the possibility to track abnormal usage in time, possible cyber-attacks, or new malfunctions of the operations that need to be provided with immediate care.

Step 6: After analyzing and deciding what to do, the algorithm studies the optimization actions that have been developed in the first steps and puts them into practice. This encompasses implementing the best decisions of routing the print jobs, revising the maintenance schedule with the devices that have been identified as anomalies, and sending anomalies notifications to the administrators of the system. These measures bring about real time adaptation and continuity in operational efficiency.

Figure 3

|

Figure

3 Flowchart Diagram of Predictive Analytics

Algorithm |

5. Interpretation & Discussion

The suggested smart print management is a combination of

predictive analytics, IoT-based monitoring, and automatic decision making to

resolve the long-standing inefficiency in enterprise print settings. This

discussion section is an interpretation of the general results of the

predictive models, its efficacy in terms of a real-world print ecosystem, and

critical analysis of the overall implication of adopting data-based strategies

in undertaking print operations. This section will bring out how the structure

will add value to better reliability, cost-effectiveness, and sustainability in

the organizational printing processes by combining the information of the

forecasting, anomaly detection, and maintenance components.

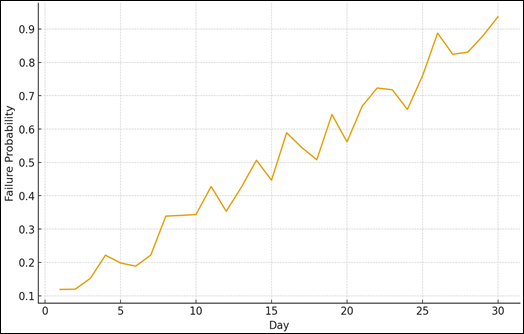

Figure 4

|

Figure

4

Actual vs Forecasted Print Volume |

Figure

4 provides the comparison of the actual volumes of print and the

forecasted values obtained by the forecasting model in 30 days. It can be

observed that the model is effective in capturing both the short

term variations and the long term periodic

variations in the daily print activity. The print volume peaks and troughs are

also closely reflected as per the predicted curve so the model is able to learn

seasonal and temporal dynamics in the workload. Minor deviations are realized

when there are sudden workload spikes and this is common in the real world office conditions whereby large-batch

print orders can be sudden. On the whole, the proximity of two curves confirms

the efficiency of the LSTM-based prediction model in terms of estimating

routine loads of printing and proactive resource distribution, load balancing,

and consumable management. The anomaly detecting part goes further with the

intelligence of the system to detect unusual patterns like an abrupt increase

in print volume, activity of unauthorized users or unusual machine behaviors. The system identifies any form of deviation

which could be an indication of a misuse of the equipment, cyber threat, or

sensor failure through the application of an autoencoder that has been trained

on the normal operational data. The feature enhances system security and

accountability, where anomalies would be raised and resolved in a timely manner

before they get out of control. It is emphasized in the discussion that anomaly

detection is not only helpful in ensuring stability in operations of an

organization, but also in adherence to organizational printing policies and

data governance.

Figure

5

|

Figure 5 Predictive Maintenance Risk Over Time |

Figure 5 indicates the estimated probability of failure of a device within the same period of 30 days. The rising curve represents a slow drop in the health condition of the device, and it correlates with the wear-and-tear patterns of the enterprise printers being used constantly. Spike variation in probability of risk is an indication of the times when the maintenance classifier was able to detect abnormal temperature fluctuation, frequency of jam, and usage stress. The system detects the fact that preventive maintenance needs to be done at scheduled intervals as the probability attains greater heights towards the end of the period, before a real failure occurs. Based on this, predictive modeling is powerful in terms of pinpointing warning signs in time, lessening downtime, and followed by timely and cost-effective maintenance actions grounded in data-driven information. A combined study of all three predictive models demand forecasting, maintenance prediction and anomaly identification the way the system works as a unified smart print environment. The models do not operate as a set of modules operating independently, but instead they affect the flow of decisions and share with each other. An example of this is that forecasted heavy loads may cause early toner replenishment and an anomaly alarm may cause temporary job rerouting around a suspicious device. The interdependency is the result of a bigger theme of the holistic orchestration where predictive insights are all used to direct automated policy enforcement and optimization of infrastructure.

Figure 6

|

Figure

6 Anomaly Score Trends with Detected Outliers |

In Figure 6, the anomaly scores of the autoencoder-based detection model are shown. The majority of day-to-day scores are close to the baseline, but on Days 6 and 21, there are two prominent spikes that indicate drastic alterations of the normal printer behavior. Such anomalies may be explained by the deviant print jobs, unauthorized access, errors with sensors, or any possible security issues like spoofed print. These outliers prove that the model is sensitive to irregularities in operations and can signal those events that might need administrative follow-up. The low background scores in normal conditions is an affirmation of the fact that the model does not create a high number of false positives and can successfully identify unusual patterns and therefore increase the level of security and operational vigilance in the print ecosystem. Nevertheless, there are some practical challenges that are mentioned in the discussion, as well. Completeness of data, reliability of sensors and consistent reporting of devices are critical aspects that determine the quality of prediction. Older printer environment, or heterogeneous fleets, could also experience sparsity or inconsistency of the data in order to impact the model accuracy. Moreover, it is necessary to support the scaling of the system to thousands of printers with strong data pipelines, edge computing support, and cloud-based analytics infrastructure. The issue of data privacy is also an issue of concern given that job logs may be sensitive organizational or personal information. Hence, the future research can consider edge-based anonymization, federated learning, or privacy-preserving analytics to reduce these risks.

6. Conclusion and Future Work

The current study proposed a Smart Print Management system that is an intelligent, data-driven predictive analytics-based system with integrated IoT-based monitoring, machine learning models, and automated decision-making. This paper has shown the functions of predictive forecasting, anomaly detection, and predictive maintenance as well as their benefits to a more resilient and cost-efficient and sustainable print environment. The relocation of the old methods of reactive response and the implementation of a single predictive structure can make organizations benefit much to utilize devices, minimize operational downtime and enhance control of printing patterns in distributed systems. The summary conveys the fact that predictive analytics represent a revolutionary breakthrough in print management as it can make it possible to take proactive actions. The forecasting model was also useful in a way that it was effective in the ability to capture the changes in work loads and forecast future print volumes with high accuracy. The ability facilitates pre-emptive routing of print jobs, which balances devices.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Advisera. (2017). Clause-By-Clause Explanation of ISO 27001. Advisera Expert Solutions Ltd.

Amendola, C., Calabrese, M., and Caputo, F. (2018). Fashion Companies and Customer Satisfaction: A Relation Mediated by ICT. Journal of Retailing and Consumer Services, 43, 251–257. https://doi.org/10.1016/j.jretconser.2018.04.003

Garcia Plaza, E., Nunez Lopez, P. J., and Beamud Gonzalez, E. M. (2018). Multi-Sensor Data Fusion for Real-Time Surface Quality Control in Automated Machining Systems. Sensors, 18(12), 4381. https://doi.org/10.3390/s18124381

Gim, J., Yang, H., and Turng, L.-S. (2023). Transfer learning of Machine Learning Models for Multi-Objective Process Optimization of a Transferred Mold. Journal of Manufacturing Processes, 87, 11–24. https://doi.org/10.1016/j.jmapro.2022.12.033

Humbert, C., et al. (2024). A Simple Method to Manufacture a Force Sensor Array Based on a Single-Material 3D-Printed Piezoresistive Foam and Metal Coating. Sensors, 24(12), 3854. https://doi.org/10.3390/s24123854

Kong, L., Peng, X., Chen, Y., Wang, P., and Xu, M. (2020). Multi-Sensor Measurement and Data Fusion Technology for Manufacturing Process Monitoring: A Literature Review. International Journal of Extreme Manufacturing, 2, 022001. https://doi.org/10.1088/2631-7990/ab7832

Kryvinska, N. (2012). Building Consistent Formal Specification for the Service Enterprise Agility Foundation. Social Services Science Journal of Service Science Research, 4, 235–269.

Lu, L., et al. (2023). Deep learning-Assisted Real-Time Defect Detection and Closed-Loop Adjustment for Additive Manufacturing of Continuous Fiber-Reinforced Polymer Composites. Robotics and Computer-Integrated Manufacturing, 79, 102431. https://doi.org/10.1016/j.rcim.2022.102431

Martínez-Mireles, J. R., Rodríguez-Flores, J., García-Márquez, M. A., Austria-Cornejo, A., and Figueroa-Díaz,

R. A. (2025). AI in Smart Manufacturing. In

Machine and Deep Learning Solutions for Achieving the

Sustainable Development goals

(pp. 463–494). IGI Global.

Molnár, E., Molnár, R., Kryvinska,

N., and Greguš, M. (2014).

Web Intelligence in Practice. Social Services Science Journal of Service

Science Research, 6, 149–172.

Shin, S.-J. (2019). A Hybrid Learning-Based Predictive Process Planning Mechanism for Cyber-Physical Production Systems. Journal of the Korean Society for Precision Engineering, 36(5), 391–400.

Sjödin, D. R., Parida, V., Leksell, M., and Petrovic, A. (2018). Smart Factory Implementation and Process Innovation. Research-Technology Management, 61(5), 22–31. https://doi.org/10.1080/08956308.2018.1471277

Tomiyama, T., Lutters, E., Stark, R., and Abramovici, M. (2019). Development Capabilities for Smart Products. CIRP Annals, 68(2), 727–750. https://doi.org/10.1016/j.cirp.2019.05.003

Vaidya, S., Ambad, P., and Bhosle, S. (2018). Industry 4.0—A Glimpse. Procedia Manufacturing, 20, 233–238. https://doi.org/10.1016/j.promfg.2018.02.034

Vogel-Heuser, B., and Hess, D. (2016). Guest Editorial: Industry 4.0—Prerequisites

and visions. IEEE Transactions on Automation Science and Engineering, 13(2),

411–413.

https://doi.org/10.1109/TASE.2016.2523639

Wang, J., Ma, Y., Zhang, L., Gao, R. X., and Wu, D. (2018). Deep Learning for Smart Manufacturing: Methods and Applications. Journal of Manufacturing Systems, 48, 144–156. https://doi.org/10.1016/j.jmsy.2018.01.003

Zhang, Z., Liu, Q., and Wu, D. (2022). Predicting Stress–Strain Curves Using Transfer Learning: Knowledge Transfer Across Polymer Composites. Materials and Design, 218, 110700. https://doi.org/10.1016/j.matdes.2022.110700

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2024. All Rights Reserved.