ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

AI in Modern Printing Design and Production

Dr. Meghana Bhilare 1![]() , Dr. Balasaheb Balkhande

2

, Dr. Balasaheb Balkhande

2![]() , Indira Priyadarsani Pradhan 3

, Indira Priyadarsani Pradhan 3![]() , Himanshu Makhija 4

, Himanshu Makhija 4![]()

![]() ,

Dr. Selvi M. 5

,

Dr. Selvi M. 5![]()

![]() ,

Avni Garg 6

,

Avni Garg 6![]()

![]()

1 Director,

Dr. D Y Patil Institute of Management and Entrepreneur Development, Varale, Talegaon Pune, India

2 Department

of Computer Engineering, Vasantdada Patil

Pratishthan’s College of Engineering and Visual Arts, Sion, Mumbai, India

3Assistant Professor,School of Business

Management, Noida international University 203201, Uttar Pradesh, India

4Centre of Research Impact

and Outcome, Chitkara University, Rajpura- 140417, Punjab, India

5Associate Professor,

Department of Computer Science and Engineering, Sathyabama Institute of Science

and Technology, Chennai, Tamil Nadu, India

6Chitkara Centre for

Research and Development, Chitkara University, Himachal Pradesh,

Solan, 174103, India

|

|

ABSTRACT |

||

|

With the

adoption of Artificial Intelligence (AI) into the contemporary printing

designing and printing processes, the conventional processes involved in the

printing industry have approached novel avenues of creativity, efficiency,

and precision, unlike before. In the past, printing has been developed and

transformed by the manual process of printing such as the letter press and

lithography to entirely automated digital printing. Nowadays, AI is the next

big thing that transforms the design and production stages. In design,

AI-based tools can be used to generate concepts automatically, dynamically

customize, and identify patterns to ensure that designers can produce visual

outcomes that are highly customized and attractive as quickly as possible.

Machine learning algorithms can make the colors matching, the patterns more

efficient, and the layouts more balanced, whereas generative AI makes it

possible to create original and adaptive designs to meet the requirements of

a particular audience or a particular branding. In manufacturing, AI tools

like predictive maintenance, automated quality control, and real-time defect

detection guarantee the consistency of the output quality without causing

much downtime and wastage of materials. Also, AI-based smart ink management

systems and material utilization systems use AI to maximize material use and

sustainability. The advantages of AI integration are felt throughout the

printing value chain- creation of operational efficiency, minimization of

costs, and accuracy, as well as availability of more personalizations

to the customers. Nonetheless, issues like implementation expenses, risks in

data privacy, Intellectual property and requirement of skilled manpower is still a major obstacle to complete implementation. |

|||

|

Received 26 January 2025 Accepted 21 April 2025 Published 10 December2025 Corresponding Author Dr.

Meghana Bhilare, meghabhilare@gmail.com DOI 10.29121/shodhkosh.v6.i1s.2025.6630 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Artificial Intelligence, Printing Design, Digital

Printing, Predictive Maintenance, Generative AI, Quality Control |

|||

1. INTRODUCTION

Printing has been an ancient foundation of human communication and art and the spread of information. Ever since the invention of the Gutenberg press in the 15th century, printing has crucially experienced innovation to support the changing needs of the society as well as business. However, since the 21st century the blistering growth of Artificial Intelligence (AI) has started to redefine the printing scene entirely the process of designing, as well as the way how the production is being managed, optimized, and delivered. The introduction of AI into the modern printing design and production is one of the most significant changes towards automation, intelligence, and personalization, which marks the new era commonly known as Smart Printing. The conventional printing process was very manual based, human based and with a lot of repetitive mechanical processes. These processes were the basis of mass communication but limited by the human factor; speed, accuracy and flexibility Johnson and Clark (2024). With the introduction of digital printing, the industry was transformed as the turnaround time became faster, short-run productions became economical, and the products could be customized. But still, digital printing had to involve human participation in the form of optimization of design, finding mistakes, and management of production. Here is where AI has created the difference between the world, as it can learn, adjust, and advance processes on its own. Machine learning (ML), deep learning, and generative algorithms are the types of AI that have brought new opportunities into the domain of both the creation of designs and the implementation of printing processes on an industrial level. In design, AI-enabled solutions can be used by artists, designers, and marketing experts to facilitate some of their daily tasks such as layouts and patterns creation, color correction. Advanced systems use Generative AI to generate original design ideas, according to user inputs, allowing personalization on a massive scale, a crucial characteristic in the modern marketing and branding environment where the individualized experience is the central source of consumer interest.

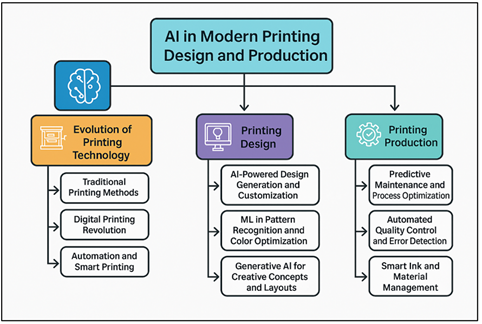

Figure 1

Figure 1 Comprehensive Model of AI Applications in Printing Design and Production

The predictive models of AI also determine the aesthetic tastes, trends in the market, and data on the user to suggest designs that meet the expectations of the audience, which minimized the creative guesswork in order to enhance its efficiency. Figure 1 indicates that AI simplifies design, manufacturing, quality and maintenance to enhance efficient printing. AI also has some far-reaching consequences in the production. Smart machines and sensors now control all projections of the printing process including the viscosity of ink and paper alignment, temperature control and precision of output Mesároš et al. (2021). This is possible because predictive maintenance systems run on AI algorithms can predict equipment failure before it happens and reduce downtime and increase machine life. Likewise, computer vision and neural networks are applied by automated quality control systems to identify defects, color anomalies or alignment errors in real-time so that only high quality prints get to the customer.

2. Related Work

During the last ten years, several researches and industry initiatives covered the application of Artificial Intelligence (AI) to the printing design and production, with a focus on its radical potential in the sphere of creativity and operations. In the early studies, the main objective was automation and color management systems in digital printing, using machine learning (ML) models to increase the accuracy of color calibration and print variability Jarrahi et al. (2023). These early papers showed that AI was able to be superior to the old manual rule-based approaches to calibration in terms of reducing manual intervention and error rates. Design automation The use of Generative Adversarial Networks (GANs), as well as deep learning models, to generate creative layouts, typography and patterns, was highlighted by Wang et al. (2018), Lee and Choi (2020) and others Rane (2023). Their works demonstrated the opportunity of the generative AI to reproduce artistic styles, hint new combinations of design, and modify visual works to suit various media. Equally, business applications such as Adobe Sensei, Magic Design by Canva and StyleGAN by NVIDIA have confirmed the pragmatic possibility of using AI-based design applications, which are now marketed at professional and consumer levels. In production-based studies, it has centered on optimization of the processes and predictive analytics. Muller and Koch and Patel et al. examined the use of AI as a predictive maintenance tool, allowing printers to predict the wear of their parts, a lack of ink, and other mechanical failures through the analysis of sensor data Ahmad et al. (2024). These systems use neural networking and data modeling as a method of avoiding downtime and improving availability and minimizing maintenance expenses. In addition, Table 1 presents the main research works that indicate the influence of AI on the innovation of printing. Computer vision-based AI-based quality inspection systems have been applied in the large-scale print manufacturing, where defects could be identified in real-time and automatic error fixing was performed.

Table 1

|

Table 1 Summary on AI in Modern Printing Design and Production |

||||

|

System Name |

Focus Area |

AI Technique Used |

Application in Printing |

Future Scope |

|

AI-Based Layout Generator |

Design Automation |

Deep Learning |

Automated layout creation |

Limited style diversity |

|

GAN Design Model Chen et al. (2021) |

Creative Design |

Generative Adversarial Networks (GANs) |

Artistic pattern and typography generation |

Needs better semantic control |

|

SmartPrint AI |

Process Optimization |

Reinforcement Learning |

Workflow and resource optimization |

Needs cross-platform integration |

|

DeepColor AI Bao et al. (2022) |

Color Calibration |

Neural Networks |

Adaptive color

management |

Limited to specific substrates |

|

AutoInspect Yaseen et al. (2020) |

Quality Control |

Computer Vision |

Defect detection in print outputs |

Requires high-resolution imaging |

|

Adobe Sensei |

Design and Automation |

Deep Neural Networks |

Design assistance and automation |

Proprietary, limited customization |

|

EcoPrint Píry et al. (2023) |

Sustainable Printing |

Predictive Analytics |

Ink and resource optimization |

Needs broader environmental dataset |

|

PrintGAN |

Generative Printing |

GAN-based Model |

Layout and pattern generation |

Limited interpretability of results |

|

AutoColorNet |

Color Optimization |

Convolutional Neural Networks (CNNs) |

Dynamic color

correction |

Requires large training datasets |

|

SmartInk Manager Revolti et al. (2024) |

Ink Management |

Data Analytics |

Real-time ink monitoring |

Dependent on sensor calibration |

|

StyleGAN3 for Print |

Generative Design |

GAN + Transformer |

Artistic layout synthesis |

High GPU demand |

3. Evolution of Printing Technology

3.1. Traditional Printing Methods

The origin of the printing industry is the old methods of printing that formed the communication, art and documentation over the centuries. The first significant development came with the movable type printing press invented by Johannes Gutenberg in the 15th century which transformed the process of mass communication by allowing books and other documents to be produced in large and standard amounts. With time, there came a number of conventional printing techniques each with a specific purpose. An example is the letterpress printing where the raised metal type was used to stamp ink onto paper and produced sharp and feelable impressions Khan et al. (2025). Lithography was invented in the 18th century and depended on the immiscibility of oil and water to carry fine images, which led to the reproduction of a high quality image. Subsequently the offset printing technique was the leading technique because of its efficiency, accuracy and capacity to produce in large quantity. Yet, in spite of their historical importance, these traditional methods were not without their disadvantages: high cost of set-up, lengthy preparation and low flexibility in customization Marović et al. (2022). Changes in design would demand physical changes and small-batch printing could not be economically viable. However, conventional printing developed the necessary level of standards in reproduction of colors, handling of materials and craftsmanship that still have an impact into the contemporary printing practices. These approaches provided the foundation to other subsequent innovations, where the focus was on quality and reliability. With the change of the industrial and consumer demands, the necessity of quicker, more adaptable, and economical solutions gave birth to the change in the digital and automated printing technologies, which preconditioned the technological breakthrough that happened in the subsequent years Zhang et al. (2022).

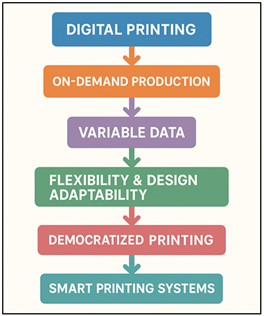

3.2. Digital Printing Revolution

The technological advent of digital printing at the end of the 20 th century created a major paradigm shift in the printing industry as it crossed the boundary of human craft and smart automation. Digital printing in contrast to the traditional print where the physical plates were used, is a direct transfer of digital files on some substrates through inkjet or laser-based printing. This breakthrough had a significant decrease in the time and cost of setup with the result being shorter turnarounds and low-cost short runs Zhang and Teizer (2018). With digital printing came the production on demand, whereby businesses could print on variable data, like a name, serial number, or custom message, without affecting the workflow or commonly having to make mechanical adjustments. High flexibility and design adaptability of digital printing is one of the major benefits of digital printing. It provides smooth color control by use of RIP (Raster Image Processing) software which guarantees uniform quality among numerous prints. Additionally, the discovery of high-resolution imaging and the ink made of pigments increased the variety of printable substances, including paper, fabric, plastics, and metals Burnaev et al. (2023). This revolution democratized printing, which gave the enterprises and independent designers the power to use professional-grade production without the structures of an industrial scale. As Figure 2 indicates, digital printing turned the efficiency, customization and creativity around the world. Digital printing was also in line with the new digital economy where quick customization and speedy delivery was business mandate.

Figure 2

Figure 2 Evolution and Impact of the Digital Printing Revolution

It was the basis of the personalization era, which has made it possible to run data-driven marketing campaigns, and customized visual communications. Besides simplifying production, the digital revolution opened the opportunities of integrating it with AI, IoT, and automation as the next level of evolution of the printing system, smart and intelligent.

3.3. Transition Toward Automation and Smart Printing

The last and most radical stage in the history of printing technology is the shift to automation and smart printing, which will be carried out using digital printing. Following the principles introduced by Industry 4.0 and being among the sectors that have experimented with integrations of interconnected systems, AI-driven analytics, and the Internet of Things (IoT), the printing sector has progressed in terms of precision, productivity, and sustainability. Smart printing systems not only overcome the digitization but also incorporate the aspect of autonomous decisions and self-optimization Cucari et al. (2023). The current printing machines have sensors to monitor continuously such parameters as temperature, flow of inks, tension of paper and density of colors. Such sensors provide real-time information to AI programs, which interpret and make automatic adjustments to the settings to achieve stable quality and less wastage of materials. In a similar manner, predictive maintenance systems can be used to predict component failures to guarantee continuous operations and longer equipment lifetime through machine learning models. Design and production Automation tools facilitate a smooth process through the input of digital files to the ultimate product without much human intervention Sarker (2022). Online print management services also simplify the process of job scheduling, inventory management, and fulfilling orders and allow the creation of intelligent, efficiently operating, and autonomous factories.

4. Role of Artificial Intelligence in Printing Design

4.1. AI-Powered Design Generation and Customization

The use of Artificial Intelligence (AI) has influenced the creative process of printing design by allowing the automatic generation, real-time customization, and adaptive creativity. In the past, designers used to use manual tools to think about layouts, select color schemes, and develop patterns which took up way too much time and were constrained by human minds. Currently, AI-based design engine systems include Adobe Sensei, Magic Design built into Canva and AI Design Assistant by Fotor, using deep learning algorithms to process large datasets of design styles, typography, and consumer tastes. They provide automatic template of designs, layouts, and color combinations, which would fit certain brand identities or emotional contexts. Customization which used to be an expensive and cumbersome business is now streamlined by AI. Marketing resources, packaging, or promotional prints can be customized to individual customer profiles based on data-driven insights, such as the creation of customized marketing content, packaging or promotional prints. To illustrate, AI systems examine user profile and user behavior to develop designs that appeal to the target groups. This feature is particularly essential in companies such as advertising, where mass personalization would be influential in the engagement and loyalty to the brand.

4.2. Machine Learning in Pattern Recognition and Color Optimization

Machine learning (ML), which is an essential part of AI, contributes to such an important area of modern printing design as pattern recognition and color optimization. Conventional color control was based on human operators and non-dynamically controlled methods of calibration and usually resulted to variations between print batches. ML models are able to address these shortcomings by training on massive amount of color and texture data to provide automated, adaptive, and repeatable color reproduction. These systems can adjust parameters like hue, brightness and saturation by continuous learning to give an optimum visual accuracy on a variety of substrates and printing conditions. ML algorithms are used in pattern recognition to identify and format complex visual attributes such as lines, shapes, and textures to identify irregularities in design or propose design alternatives. The feature is necessary in the processes such as textile printing, packaging as well as decorative graphics where precision and repetition are paramount. In the case of convolutional neural networks (CNNs), specific patterns or distorted items of real objects that are found and rectified in real-time can be found in prepress and production processes.

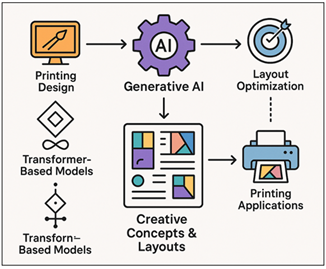

4.3. Use of Generative AI for Creative Concepts and Layouts

Generative Artificial Intelligence (GenAI) is one of the most groundbreaking technologies in printing design, which allows the machine to contemplate the unique artistic ideas, layouts, and visual images. Generative AI can be used to create original and adaptive designs unlike a traditional design software, which utilizes pre-selected templates with manual modifications. Generative Adversarial Networks (GANs) and transformer-based generative AI algorithms are used to generate the new designs. These systems are based on a large database of images, fonts, and designs, and create new layouts that are both aesthetic and functional and coherent to the brand. To designers, it implies quicker ideation and experimentation creativity. Hundreds of variations of concepts can also be generated by Generative AI in a matter of seconds, which can enable human designers to experiment with a greater design space. Figure 3 demonstrates that generative AI improves creativeness with automatic layouts and ideas. This technology is used in printing applications to create tailored packaging, posters, textile prints and marketing materials which are dynamically modified to fit client specifications or consumer data profiles.

Figure 3

Figure 3 Use of Generative AI for Creative Concepts and Layouts.

In addition to that, generative AI can also be used to optimize the layout by examining the hierarchy of content, spacing, and visual flow to produce the most optimal composition. As an example, AI is able to modify such features as the positioning of typography or image size and improve readability and visual balance on its own. It is also capable of producing the appearance of real-world visual results, forecasting the appearance of the designs when printed.

5. AI in Printing Production Processes

5.1. Predictive Maintenance and Process Optimization

Predictive maintenance and process optimization are among the two most effectively used applications of Artificial Intelligence (AI) in the printing production environment. Conventional maintenance plans that are based on either a timely service or reactive maintenance are mostly associated with unexpected downtime, high operational expenses and low productivity. The predictive maintenance systems are AI-based systems, which address these issues with the help of machine learning (ML) algorithms and sensor data analytics to predict equipment failures before they can take place. These systems constantly observe the critical parameters, including the level of vibration, temperature, ink viscosity, and roller pressure, and they are able to take operational data of printing machines in real time. AI identifies normal changes and anomalies that can be detected before mechanical failures set in by modeling data. The system will notify operators in case of irregularities so as to take a preventive measure to ensure that the costly interruptions are minimized. This method increases the life of a machine and enhances reliability of production. AI is also important in process optimization besides maintenance. AI systems detect the workflow efficiency, speed of production, and resource use and propose changes to improve the performance.

5.2. Automated Quality Control and Error Detection

The printing industry has consistently enjoyed quality assurance which has been enhanced by automation through AI, making the quality control more accurate and efficient than ever before. Conventional quality inspection procedures usually rely on manual inspection that may be time consuming and subject to mistakes in human error. On the contrary, AI-based quality control systems utilize computer vision, deep learning, and neural networks to identify flaws (color deviation, misalignment, smudges or missing elements) in real time automatically. The outputs of high resolution cameras are continuous streams of printed materials, which are processed through an image recognition algorithm that is trained on thousands of defect patterns. The system immediately detects irregularities, classifies mistakes and even proposes remedial actions. An example is the case where an ink density is sensed to be changing, then AI can automatically recalibrate to regain precision by adjusting the printing pressure. This does not only improve the quality of print but it also reduces wastage and reprints. Besides, AI can also be used to monitor the performance in real-time since it can compare the outputs with the digital design reference to make sure that each print matches the expectations of the clients. Advanced analytics also enable manufacturers to trace the trends in production, common problems and preventive quality measures.

5.3. Smart Ink and Material Management

AI has brought out impressive developments in ink development and material control which was previously controlled by manual calibration and trial and error. AI systems can now track, anticipate and optimize ink, coating and substrate usage with a very high level of preciseness through intelligent algorithms and real time analytics. These technologies allow printers to achieve the performance, cost-efficiency, and environmental sustainability at the same time. In intelligent ink handling, printing machines provided with sensors measure the viscosity, temperature, and pigment concentration. This data is analyzed by AI models to dynamically change the ink flow rates and mixing ratios to and achieve the same reproduction of colors and to avoid waste. This generation-in-real-time optimization ensures consistency in large volumes of prints as well as the different types of materials used which include paper, textiles, plastics etc. also helps in the development of eco-friendly inks by modeling the chemical reaction and how the results will be performed before any physical experiment. It will speed up the creation of sustainable materials and minimize the use of resources in the experimentation process. In the sphere of material management, AI based logistics systems predict needs in materials, plan optimal storage, and automatize re-ordering. Predictive analytics assists in estimating the quantity used in the substrates from past data and demand to avert overstocking or below the required quantity.

6. Benefits of AI Integration in Printing Industry

6.1. Enhanced Efficiency and Cost Reduction

The printing industry is one of the sectors that have received high efficiency, cost control, and operational flexibility due to the adoption of Artificial Intelligence (AI). Conventional printing processes can have several steps design, prepress, printing, and finishing, where each step requires a process to be handled manually and checked by hand. With AI, a number of these processes become automated and, therefore, can be completed within a shorter period of time and reduced human error. Using predictive analytics, AI systems are able to predict the wear of machines, optimize ink consumption, and dynamically adjust printing settings to make sure that a production process is not interrupted in an unjustified way. Predictive maintenance and automated scheduling are one of the most influential benefits that allow minimizing downtime. AI finds problems in work process, resource redistribution, and provides real-time suggestions regarding process changes. It results in increased production with a little wastage of resources, work, and energy.

6.2. Improved Accuracy and Consistency

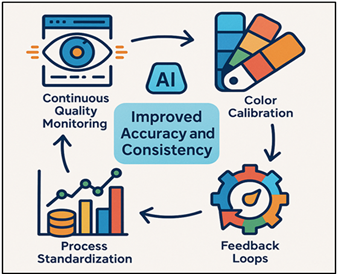

Reliability and consistency matter in the printing business, where any minor changes in color, alignment or texture would affect the quality of the product and brand integrity. Artificial Intelligence (AI) adoption solves such issues by providing an automation of precision and continuous quality control. AI-based applications use computer vision and algorithms of machine learning to investigate all elements of the printing process: identify color defects, and printing errors, and distortion of the pattern during the process. In contrast to the manual inspection approach, AI guarantees twenty-four-hour, objective assessment, and consistency remains the same in thousands of prints.

Figure 4

Figure 4 AI-Driven Accuracy and Consistency in Printing

Processes

As an illustration, intelligent color calibration algorithms ensure color fidelity to multiple print runs and materials and operating environments. In Figure 4, AI is used to guarantee accuracy, consistency and consistency in printing. Likewise, AI-based feedback loops will automatically correct deviations the moment that they are detected to ensure that every output is identical to the original design requirements. Standardization also enhances consistency in the processes. The AI logs the production data in real-time, and with each print job, it improves its machine settings to operate the machine further. This ability of the self-learning is used to make sure that the successive prints will have the experience, and this will diminish variability with time.

6.3. Personalization and Customer-Centric Solutions

Personalization has been a defining point of difference in the modern-day marketplace, and AI-based printing technologies are leading the charge on permitting customer-centered innovation. The old form of printing underlined consistency and huge production volumes, but AI brings the opportunity to produce highly personalized, data-driven products to suit individual preferences of a customer. This is done by use of algorithms which examine consumer data including demographics, purchase history, and insights on how the audience behaves in order to create distinctive designs, packaging, or even promotional content. As an illustration, a variable data printing (VDP) system using AI enables the dynamical modification of text, images, and color schemes in one printing run, which can be personalized by mass and it is affordable. In the marketing sphere, AI systems will have the capability of creating targeted visual content that matches the emotions of customers as well as their cultural background, which will boost engagement and brand loyalty. Additionally, the generative design models develop adaptive layout, which automatically adapts to the brand identity of the customer or the language of the region so that it remains relevant and appealing. The other aspect that AI boosts is user interaction, online customization, where customers are able to preview, edit, and approve designs in real time before printing. Through these innovations, not only customer satisfaction is enhanced, but also the businesses become capable of reacting swiftly to the changing market trends.

7. Challenges and Limitations

7.1. High Implementation Costs

The implementation cost is highly expensive as one of the major issues in integrating Artificial Intelligence (AI) into the printing industry. Implementation of AI-based systems needs high investment in machinery, programs, and infrastructure. The traditional printing equipment used by modern printing facilities needs to be upgraded with sensors, IoT components, and high-performance computing to provide real-time data gathering and analysis. Also, the acquisition of AI-enhanced design software, predictive maintenance software, and cloud-based workflow management software include periodic expenses of licensure, upkeep and information warehouse. Small and medium-sized enterprises (SMEs) and which constitute a significant part of the global printing industry are in most cases unable to cover these expenses because they have small budgets and do not know whether they will get the returns on the investment. The first implementation and integration may also be complicated and need technocratic skills and adaptation to prevailing work process. Additionally, to ensure that AI systems are efficient, constant updates and algorithms training are required, which contributes to operational costs. Whereas large printing companies can offset these expenses by increasing their productivity in the long term, smaller organizations can endure financial burdens or be forced to rely on third-party service providers. The absence of unified guidelines on the use of AI also makes the implementation more difficult, which results in inefficiencies and non-consistent performance results. Therefore, despite the transformational potential of AI, its application is still limited due to the lack of economic and infrastructural conditions, and the reduction of costs and models of available technologies are important to facilitate large-scale application in industry.

7.2. Data Privacy and Intellectual Property Issues

The introduction of Artificial Intelligence (AI) into the printing process brings forth technical issues of information privacy and intellectual property (IP). The AI systems are highly dependent on big data training, customer data, proprietary designs, and manufacturing information. Such dependence exposes the possibility of data breach, unauthorized entry onto the data, and misuse of confidential information. In design and customization processes, the graphics, logos, or personal details of a client are usually stored in cloud-based applications, and in case this is not properly secured, may serve as a means of a cyberattack. Moreover, when artificial intelligence generative tools are used, the issue of intellectual property rights becomes critical. In cases where AI algorithms generate or alter designs, it is unclear who the appropriate creator should be, the human designer, the AI-based system or the organization, which is legally ambiguous. This creates potential problems in copyright protection, licensing and commercial exploitation. Also, AI models that are trained on publicly accessible information can potentially reproduce copyrighted works, which can result in legal and ethical controversies (data privacy laws, including the General Data Protection Regulation, GDPR, demand organizations to be transparent and get permission and keep data safe). Nonetheless, adherence may be costly, particularly to small and medium businesses that do not have sophisticated cybernetics in place.

7.3. Skill Gaps and Workforce Adaptation

The effectiveness of using Artificial Intelligence (AI) in the printing sector is commonly limited by the lack of skills and difficulties in the workforce adjustment. The classical printing professionals who are used to working in a manual or semi-digital environment might struggle with adapting to the systems based on AI that demand knowledge in data analytics, automation, and digital processes management. The transition to intelligent printing spaces requires new technical skills in machine learning, computer vision, and IoT integration, which are currently uncommon in most areas unless employees reform or upgrade their skills. Mechanical printing operators might also be rendered obsolete due to the automation of tasks like color correction, error correction and workflow optimization by AI. On the other hand, the demand of AI engineers, data scientists, and digital process managers is increasing, which leads to the lack of balance between the available expertise and needs in industries.Organizations cannot conduct continuous training and reskilling programs because of the financial limitations and time constraints. Moreover, change can face resistance particularly among the experienced personnel, thus affecting the adoption efforts. An effective transition cannot be made without a technical training but also without a cultural change - encouraging cooperation between human creativity and machine intelligence.

8. Conclusion

The introduction of the concept of Artificial Intelligence (AI) into the contemporary printing design and production is a revolutionary stage in the history of the printing industry. Since the ancient days of manual labour in the process of printing, the art of printing has evolved with the changing market needs. AI is the peak of this advancement - being able to think, learn, and utilize human creativity, it creates layouts, color schemes, and visual compositions with little human interaction.AI technology is being used in the design industry to create layouts, color schemes, and visual compositions with a minimum of human input. Machine learning and generative-powered tools have transformed design processes in a more customer-oriented, data-driven and intuitively designed way. In the meantime, AI is used in the production floor to achieve operational excellence by predicting maintenance, optimizing processes in real-time, and automated quality control. These innovations do not only save on downtimes and waste, but also overall production sustainability and consistency. Nevertheless, the shift to the AI-based printing will not be easy. Implementation expenses are high, privacy of data and skill gaps are still limiting its adoption especially by small and medium enterprises.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Ahmad, K., Iqbal, W., El-Hassan, A., Qadir, J., Benhaddou, D., Ayyash, M., and Al-Fuqaha, A. (2024). Data-Driven Artificial Intelligence in Education: A Comprehensive Review. IEEE Transactions on Learning Technologies, 17, 12–31. https://doi.org/10.1109/TLT.2023.3314610

Bao, Y., Hilary, G., and Ke, B. (2022). Artificial Intelligence and Fraud Detection. In Innovative Technology at the Interface of Finance and Operations (223–247). Springer. https://doi.org/10.1007/978-3-030-75729-8_8

Burnaev, E., Mironov, E., Shpilman, A., Mironenko, M., and Katalevsky, D. (2023). Practical AI Cases for Solving ESG Challenges. Sustainability, 15(17), Article 12731. https://doi.org/10.3390/su151712731

Chen, J., Lim, C. P., Tan, K. H., Govindan, K., and Kumar, A. (2021). Artificial Intelligence-Based Human-Centric Decision Support Framework: An Application to Predictive Maintenance in Asset Management Under Pandemic Environments. Annals of Operations Research, 1–24. https://doi.org/10.1007/s10479-021-04373-w

Cucari, N., Nevi, G., Laviola, F., and Barbagli, L. (2023). Artificial Intelligence and Environmental Social Governance: An Exploratory Landscape of AI toolkit. SSRN Electronic Journal, 1–15. https://doi.org/10.2139/ssrn.4629933

Jarrahi, M. H., Askay, D., Eshraghi, A., and Smith, P. (2023). Artificial Intelligence and Knowledge Management: A Partnership Between Human and AI. Business Horizons, 66, 87–99. https://doi.org/10.1016/j.bushor.2022.03.002

Johnson, M., and Clark, R. (2024). AI-Driven Approaches to Risk Management in Construction. Journal of Construction Engineering and Management, 91, 1–16.

Khan, N., Ansari, S., Tabassum, S. Z., Nikam, D., and Jambhulkar, A. (2025). Pointers – CSE Learning Management System. International Journal of Electrical and Electronics Computer Science (IJEECS), 14(1), 225–231.

Marović, I., Hanak, T., and Plaum, S. (2022). Performance Management in Civil Engineering: A Systematic Literature Review. Electronic Journal of the Faculty of Civil Engineering Osijek, 13, 47–58. https://doi.org/10.13167/2022.24.5

Mesároš, P., Behúnová, A., Mandičák, T., Behún, M., and Krajníková, K. (2021). Impact of Enterprise Information Systems on Selected Key Performance indicators in construction project management: An empirical study. Wireless Networks, 27, 1641–1648. https://doi.org/10.1007/s11276-019-02048-w

Píry, M., Škorvagová, E., and Decký, M. (2023). Green Infrastructure: Legislative and Behavioral Approaches in the Context of Urban Engineering. Civil and Environmental Engineering, 19, 748–757. https://doi.org/10.2478/cee-2023-0068

Rane, N. (2023). Integrating Building Information Modelling (BIM) and Artificial Intelligence (AI) for Smart Construction Schedule, Cost, Quality, and Safety Management: Challenges and Opportunities. SSRN Electronic Journal, 15, 1–20. https://doi.org/10.2139/ssrn.4616055

Revolti, A., Gualtieri, L., Pauwels, P., and Dallasega, P. (2024). From Building Information Modeling to Construction Digital Twin: A Conceptual Framework. Production and Manufacturing Research, 12(1), Article 2387679. https://doi.org/10.1080/21693277.2024.2387679

Sarker, I. H. (2022). AI-Based Modeling: Techniques, Applications and Research Issues Towards Automation, Intelligent and Smart Systems. SN Computer Science, 3, Article 158. https://doi.org/10.1007/s42979-022-01043-x

Yaseen, Z. M., Ali, Z. H., Salih, S. Q., and Al-Ansari, N. (2020). Prediction of Risk Delay in Construction Projects Using a Hybrid Artificial Intelligence Model. Sustainability, 12(4), Article 1514. https://doi.org/10.3390/su12041514

Zhang, F., Chan, A. P. C., Darko, A., Chen, Z., and Li, D. (2022). Integrated Applications of Building Information Modeling and Artificial Intelligence Techniques in the AEC/FM Industry. Automation in Construction, 139, Article 104289. https://doi.org/10.1016/j.autcon.2022.104289

Zhang, Y., and Teizer, J. (2018). Artificial Intelligence in Construction Safety: Current use and Future Challenges. Safety Science, 33, 1–13.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2024. All Rights Reserved.