ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

3D Printing and AI-Guided Sculpture Fabrication

Prerak Sudan 1![]()

![]() ,

B Reddy 2

,

B Reddy 2![]()

![]() , Anand S. Relkar 3

, Anand S. Relkar 3![]() , Vaibhaw R Doifode 4

, Vaibhaw R Doifode 4![]() , Surendra Babu K 5

, Surendra Babu K 5![]()

![]() , Dr. Vikas Sagar 6

, Dr. Vikas Sagar 6![]()

![]()

1 Centre

of Research Impact and Outcome, Chitkara University, Rajpura, Punjab, India

2 Chitkara

Centre for Research and Development, Chitkara University, Himachal Pradesh,

Solan, India

3 Department of Mechanical Engineering, Matoshri Aasarabai Institute of

Technology and Research Centre, Nashik, Maharashtra, India

4 Department of Electrical Engineering, Yeshwantrao Chavan College of

Engineering, Nagpur, Maharashtra, India

5 Associate Professor, Department of Mechanical Engineering, Aarupadai

Veedu Institute of Technology, Vinayaka Mission’s Research Foundation (DU),

Tamil Nadu, India

6 Assistant Professor, Department of Computer Science and Engineering (AI),

Noida Institute of Engineering and Technology, Greater Noida, Uttar Pradesh,

India

|

|

ABSTRACT |

||

|

This study

looks at how 3D printing and artificial intelligence (AI) are coming together

in the field of sculpture manufacturing, focussing

on how they are changing the way art is made, how quickly it can be made, and

how it looks in general. The research examines how AI-powered design models

and computer creativity can aid people in thinking of new ideas by creating

complex sculptures with human assistance. In this research the relationship

between human intention and computer activity is being reconceptualized in

contemporary art practice within a framework of digital aesthetics, machine

learning and material science. The theoretical background focuses on how

additive manufacturing has evolved in the creative areas, the use of

AI-assisted generative design, and the social issues that arise when

machine-generated art is produced. The project takes an experimental approach

to the generation of led AI models by using a mix of neural networks,

computer-aided design (CAD) systems and 3D printer tools to create and test

the models. The suggested system design consists of training models,

integrating process between artificial intelligence and printers and optimising materials for accurate manufacturing.

Comparing sculptures that were made by humans and those that were made by AI

can help us understand how to make better statues and come up with new

designs. The sample building results show that it is possible to build

complex structures that weren't possible before, thanks to the AI-guided 3D

printing technology, which also reduces waste and the need for human

assistance. |

|||

|

Received 26 January 2025 Accepted 21 April 2025 Published 10 December 2025 Corresponding Author Prerak

Sudan, prerak.sudan.orp@chitkara.edu.in DOI 10.29121/shodhkosh.v6.i1s.2025.6629 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: 3D Printing, Artificial Intelligence, Generative

Art, Digital Aesthetics, Computational Creativity, Sculpture Fabrication |

|||

1. INTRODUCTION

The way people express themselves creatively in the twenty-first century has changed due to the way in which art, technology, and artificial intelligence work together. 3D printing and AI-guided generative design are two of the most important new technologies in this merger. They are both changing the way the sculptures are made in traditional ways. Sculpture has always been a very human activity that required fine motor skills, understanding of materials and a close link to the artist's mind and understanding of the object in itself. While digital manufacturing and smart programs have been trending these days, they have altered the way artists think, produce, and create their art. The combination of 3D printing (also known as additive manufacturing) with AI technologies not only impacts the way art is created, but also how human and computer creativity, responsibility and collaboration are redefined. 3D printing allows complex shapes to be built layer by layer with such accuracy and material efficiency that conventional carving cannot. Being able to transform digital ideas directly into real things, this bridges the gap between virtual thought and physical reality Thomas (2022). When AI, and in particular machine learning and neural networks, are utilized with 3D printing, it no longer becomes a tool, but a member of an intelligent creative ecosystem.

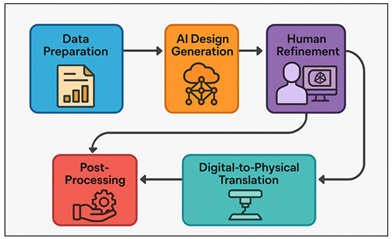

AI programs are now able to look for trends, make shapes and imitate different types of art, that means they can actually assist people make artistic decisions. Artificial intelligence (AI)-guided sculpture creation opens up new ways for people to be creative using generative models that are able to create new and surprising art. More and more the artists and experts are considering how computational creativity - the fact that machines are able to do things which are perceived to be creative - can improve or even challenge human values Boretti (2024). Neural networks that have been taught on records of art history, natural forms or abstract patterns, can create sculptures with very complicated shapes that are beyond the limits of what is physically possible or what can be seen with the human eye. In this new way of thinking, the artist is more like a director, or a partner; he directs the AI's creative process, makes its output better, and adds human intention to automated creation. Figure 1 illustrates the whole process from the AI design to the 3D sculpture fabrication. The aim of this study is to explore the possibilities of the combination of 3D printing and imagination powered by artificial intelligence to create sculptures.

Figure 1

Figure 1 System Architecture of AI-Guided 3D Printing and

Sculpture Fabrication

Not only does it look into the technical process, that includes training models, integrating software and choosing materials, but it also looks into the psychological and theoretical effects of this partnership between humans and machines. When the design of a work of sculpture is generated from a computer rather than from a person, the questions of ownership, validity, and the value of art are raised Metal (2023). So, the dialogue between the aesthetics of the digital and the machine creation is very important in order to know how the new technologies alter the art today.

2. Background and Literature Review

1) Evolution

of 3D printing technology in art and design

Additive manufacturing, which is another name for 3D printing, has changed the way the art, design, and creative output is done. 3D printing was first created in the 1980s for industrial testing. Since then, it has expanded into a number of other disciplines, including the building, fashion, and fine arts. Its main feature - the ability to build three dimensions things from computer models one layer at a time - gives artists more room and accuracy than ever before Srivastava et al. (2025). It is now possible for artists to create complicated shapes which were therefore difficult to cut, mould or cast. In its beginning 3D printing was primarily used to make copies of real models. Contemporary artists on the other hand, use it to create original works rather than copies. Computer-aided design (CAD) tools, high-resolution printers, and more varieties of materials, such as bioplastics, metal, resin, and ceramics, have all contributed to making this change possible Wang et al. (2023). When using digital modelling and physical output together as artists, it is possible to explore new aspects of creativity that combine the virtual and the real. 3D printing has become a way for design students and professionals to connect their ideas with things that they need to make. It provides for the possibility of the creation of creative shapes which challenge traditional ideas of workmanship. Important leaders like NeriOxman, Joshua Harker and Nick Ervinck have demonstrated the use of additive manufacturing to create complicated, biomimetic and computer-inspired art Freeman et al. (2022).

2) AI

applications in generative and computational creativity

Artificial intelligence (AI) has become a major force in the creative industries, which led to the notion of computational creativity. In this field, machines behave similarly in terms of creativity and thinking as humans do. AI systems, particularly those based on machine learning, deep neural networks, and evolutionary algorithms, can be used to create new songs, artworks, and patterns in the visual and artistic fields Bende et al. (2023). These technologies can take a peek into very large datasets, find underlying structures, and make new pieces based on learnt styles or rules of aesthetics. In generative art, the most common AI applications are algorithms such as Generative Adversarial Networks (GANs), and VariationalAutoencoders (VAEs) which generate new results by learning from existing datasets of art Yeshiwas et al. (2025). Mario Klingemann, RefikAnadol and Sougwen Chung are some of the artists and experts who were the first to use AI to co-create art with machines, combining human insight and computer reasoning. Because the creative process entails both human direction and machine agency, the works that are made query common ideas of creation and authorship Zhou et al. (2024).

3) Previous

research on automated sculpture fabrication

Robotics, AI, and digital-production are all areas of study that are connected to the study of making sculptures automatically. Over the last 20 years, there have been many studies conducted on how technology can help make sculptures more accurate, faster and more creative. Robotic milling and CNC cutting were the primary areas of initial study. These were ways to create real shapes from the digital models from subtractive methods Ajani and Wanjari (2013). But with the emergence of 3D printing, the additive and mixed manufacturing approach took control and made it more complex, reducing waste. Researchers like Hendrik Stuhlemmer, DimitrisGkoumas, NeriOxman etc, have helped us understand how computational design can be used to lead automated manufacturing in art settings Wang et al. (2023). AI-guided modeling - the latest in modeling systems is the use of neural networks to develop or optimize 3D shape prior to manufacture. This is the link between the fields of generative design and physical production. These systems are based on feedback loops between computer modelling and the materialisation of the forms in reality for making them more stable and aesthetically pleasing. MIT's Mediated Matter Group's voxel-based production and robotic clay printing are two examples of experimental projects that demonstrate the extent to which automation can be used to copy and amplify human artistic movements Yampolskiy et al. (2022). Studies indicate that co-creative human-machine systems are possible. In these systems, artists can direct art-making programs that create art by themselves. However, issues remain with creative possession, emotional expression and material volatility. Table 1 presents the earlier research that combines AI and 3D printing techniques. This body of study defines automatic sculpture manufacturing as one of those fields where artistic purpose, computer reasoning and mechanical accuracy all meet. This makes the way sculpture artists make new pieces of art different from the way they used to.

Table 1

|

Table 1 Summary of Related Work in 3D Printing and AI-Guided Sculpture Fabrication |

|||||

|

Study Focus |

AI Technique Used |

3D Printing Method |

Key Contribution |

Outcome |

Limitations |

|

Mediated Matter Project Haque et al.

(2023) |

Algorithmic Design |

SLA / Bio-printing |

Integration of organic

design with computational fabrication |

Demonstrated bio-inspired

sculptures with computational geometry |

Limited to lab-scale

fabrication |

|

Neural Generative Artworks |

GANs |

FDM |

Used neural networks for aesthetic pattern generation |

Produced novel forms via machine imagination |

No direct physical realization |

|

AI Data Sculptures |

Deep Learning (CNN) |

SLA |

Translated data into dynamic

3D visual structures |

Created immersive

data-driven sculptures |

Focused on visualization,

not fabrication |

|

Human–Robot Co-Creation Sheela et al.

(2025) |

Reinforcement Learning |

FDM |

Explored human-AI collaboration in artistic expression |

Enhanced creative process through co-production |

Artistic bias affects reproducibility |

|

Automated Sculptural

Fabrication |

Genetic Algorithms |

SLS |

Applied AI optimization to

physical sculpture production |

Achieved improved surface

geometry |

Limited artistic

interpretation |

|

Voxel-Based Design Systems |

Neural Architecture |

SLA |

Layered voxel computation for design precision |

Enabled micro-structural control in sculpture |

High computational cost |

|

Digital Organic Sculptures |

Parametric Modeling |

FDM |

Fusion of digital form and

material complexity |

Expanded biomorphic

aesthetic possibilities |

Lacks AI-based adaptability |

|

DALL·E 3D Shape Generation Hassan et al. (2024) |

Transformer Models |

SLA |

Text-to-3D generation using language prompts |

Produced conceptual sculptures automatically |

Early-stage physical realization |

|

Generative Design for Art

Objects |

Evolutionary Algorithms |

SLM |

AI-driven optimization of

artistic geometry |

Reduced weight while

maintaining form integrity |

Limited aesthetic

flexibility |

|

AI-Assisted Ceramic Printing |

CNN and GAN Hybrid |

Clay Printing |

Combined AI patterning with traditional materials |

Achieved hybrid cultural–technological aesthetics |

Difficult real-time correction |

3. Theoretical Framework

1) Concepts

of digital aesthetics and machine creativity

These new concepts surrounding digital aesthetics and machine creation have altered our thoughts regarding art in this age of AI. Digital aesthetics is the science of digital media and the way it influences our senses and thoughts. It focusses on the topic of how algorithms, data and math change the way we see and understand art. Digital aesthetics places a greater value on immateriality, interaction and the changing nature of digital expression than traditional aesthetics, which is based on making things out of matter. It expands the possibilities of what is possible between the author, the medium and the audience by converting the making of art into a process informed by code and computation Johnson et al. (2025). The study of machine innovation on the other hand, looks into the ways in which computer programs can come up with new things or ideas that make sense and look good. By using neural networks, genetic algorithms, and reinforcement learning, AI systems can recognize trends, mix styles, and find new ways to express themselves in an artistic way, which is why they can be creative in a way that is similar to how humans are creative. The idea behind machine creativity is taken from cognitive science, computational theory, and philosophy of mind Panico et al. (2025). It raises the question of whether creativity is something exclusive to humans or whether it can be replicated by smart computers. When such ideas are applied to art and design, it makes it more difficult to distinguish the difference between talent and automation.

2) Human–machine

collaboration in artistic expression

A human-machine collaboration has become an important element in the twenty-first-century art, offering a new approach to thinking about creation where humans and computers are involved in the creative process. In this mixed framework, the artist's job ceases to be concerned with the sole act of making art and instead focuses on designing methods through which art can be made on its own or with some assistance. The collaboration is not just a means to an end, but a dialogue between gut and math, intuition and reason, and unrestrained instantaneous and structure. When AI and 3D printing are used in combination, artists are working in a feedback loop where human visual judgement is used to guide the training and editing of AI models, and then the machine provides surprising variations which stimulate the creation of new creative directions. This looping connection promotes new ideas by going beyond the bounds of individual human understanding. Machine learning frameworks and frameworks involving modular design such as Generative Adversarial Networks (GANs) ease these kinds of interactions. This makes the creative process more of an active sharing of power. From an academic perspective, the close collaboration with machines challenges the ideas of who is the author and what is novel, which are long-standing.

3) Ethical

and philosophical considerations of AI-generated art

Much of the work that AI produces raises big moral and psychological questions over authorship, originality and creativity. From time immemorial, art has been regarded as a medium through which people can express themselves - emotionally and intellectually. But in the case of machines that produce objects that are aesthetically pleasing, it is difficult to say what constitutes aesthetic value. Can a program actually "create" something, or is it just performing the trends that were artificially implemented for data sets by humans? This is the central philosophical question that is being discussed when people discuss AI and art. The ethical considerations of AI systems producing works that rely on current human works include intellectual property and validity. There are issues of ownership and fair use because these systems are trained over very large bodies of work, often against the wishes of the original artists. Other concerns have also been raised about the sale of art, where mechanised products may result in human work and personal involvement in artistic practice becoming devalued. Philosophically, AI art raises the notion of what it means to be human by spreading out creation. Posthuman aesthetics is the notion that creativity is not only restricted to the human mind but can also be found in other systems of technology. But the lack of awareness does over into the idea of meaning and purpose, such as whether or not art created without human sentiment can be considered to have meaning.

4. Methodology

1) Research design and data collection methods

· Research design methods of data collection

This research project employs a mixed-method research design involving qualitative and quantitative research to investigate the workings and outcomes of AI-guided 3D model manufacturing. The main objective is to study how with the help of artificial intelligence it is possible to create, improve and make physical sculptures with the help of digital manufacturing. The research is concerned with the interaction between artists and computer systems and includes the evaluation of aesthetics, the assessment of technical quality and the collaborative art creation. Collection of data has three major facets including experiment design, experiment observation, and experiment assessment. First, a series of sculpture samples are created by using drawings from AI to print using 3D printing. In each step, there are some factors written down, such as model complexity, print accuracy, material use, and structure safety. Likewise, qualitative data are obtained through expert interviews, artist notes and reflecting writings that can be used to determine the meanings of creative involvement and perceived artistic value.

2) Tools and technologies used (e.g., CAD, neural networks, printers)

This study is possible because of an ecology of artificial intelligence (AI) programs, computer-aided design (CAD) systems, and 3D printing technologies. All these tools are interconnected to simplify the entire process of creating an AI-powered art piece, starting from the idea and ending with the piece itself. In the AI layer however, novel 3D shapes are created with the assistance of neural networks such as Generative Adversarial Networks (GANs) and Convolutional Neural Networks (CNNs). GANs can learn from collections of natural structures, historical statues and digital art models to make new works with complicated shapes. Parametric modelling is then used to enhance the 3D models generated using Rhinoceros 3D and Grasshopper. These tools allow artists to finely tweak computer-generated outputs. 3D printers using either the fused deposition modelling (FDM) or the stereolithographic 3D (SLA) processes are used to produce objects depending on the surface and material requirements. Some of the materials used are recyclable PLA, plastic, and hybrid fibers that are stable and exhibit fine details. Simulation software is used in the process as well and is used to verify the stress distribution, surface evenness, and physical stability before the printing process. Python-based artificial intelligence frameworks such as TensorFlow and PyTorch are used in the processing and display of data.

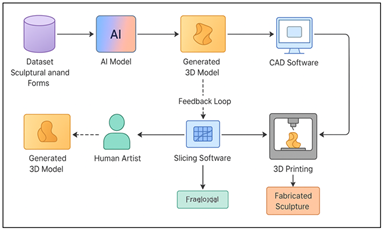

3) Workflow

of AI-guided sculpture generation and fabrication

AI-guided art creation and manufacturing is a process that involves a number of steps that are combined to integrate computer creativity, digital modeling, and physical production. The first step is to process the data. This is an edited package of natural and artistic shapes that is used to teach the AI model. The neural network can study form, symmetry, and balance through seeing the patterns in the beautiful and structures in these datasets. Next, in the phase of design generation, algorithms that have been learnt (usually GANs, or variationalautoencoders) are used to generate a variety of 3D shape options. These products are then cleaned up and refined by artists using parametric modelling or CAD software. This stage is where the aesthetic judgement and computer logic come together, where a person and a machine together make something. Once the design has been selected, it is mapped from digital to physical through the process of making the design ready for 3D printing.

Figure 2

Figure 2 Workflow Architecture of AI-Guided Sculpture

Generation and Fabricatio

With the help of slicing software, the finalised models are converted into the printed G-code. Figure 2 depicts the workflow structure of AI-assisted design, generation and fabrication of sculptures. Then, parameters such as layer height, fill density and support structure are optimised to ensure the best material usage and highest accuracy of surfaces. The chosen material (PLA, plastic, or hybrid) is loaded into the printer, and its production begins automatically. Surface cleaning, smoothing and fixing mistakes are all parts of post processing that ensure that the work's artistic and structural integrity. During the entire process performance measures (such as printing time and correct dimensions) as well as artistic ratings (such as creativity and visual cohesion) are constantly written down. This looping process enables repeated learning, which promotes better working of AI intelligence and artistic skill to make sculptures.

4) Evaluation

metrics for artistic quality and precision

The evaluation of AI-directed statues could be carried out by employing a system that combines both objective evaluation criteria and subjective artistic judgment. This ensures that both the technical correctness and the aesthetic quality of the manufactured items is measured properly. Metrics for the numeric side include things like accurate measurements, smooth surfaces, strong structures, and the use of materials efficiently. 3D scanning tool, computer-aided verification software are used to check these by comparing the printed object to its digital model. To find out about mechanical dependability and printing accuracy tolerance analysis and layer-bond tests are used. Signs to optimize production, such as efficiency indicators such as time spent printing, energy consumption, and waste, enable us to learn to optimize production. Professional groups composed of artists, designers, and art thinkers make qualitative assessments of the work. Aesthetic harmony, inventiveness, emotional power, and conceptual richness are some of the criteria that are used to evaluate work. Each work produced by AI is evaluated by specialists on the basis of the communication of an artistic intention and the visual impact, compared to statues made by people. Audience perception studies also form part of the review.

5. System Architecture and Process Design

1) AI

design model training and optimization

Art generation through AI is founded upon the idea of training AI design models. Deep learning algorithms, which are primarily Generative Adversarial Networks (GANs) and VariationalAutoencoders (VAEs) are used by the system to learn complicated visual and spatial connections from big sets of artistic and biological shapes. The dataset has digital 3D models, natural shapes, and references to sculptures from the past. It was carefully selected to ensure that all the styles and structures are different. Mesh normalisation, feature extraction and dimensional reduction are all parts of data preparation aimed at improving model performance and reducing the computational noise. During training, the generation network creates some new 3D shapes and the discriminator then checks whether these new shapes make sense and are realistic. As the model learns more it becomes better at making shapes that are both aesthetically pleasing to the eye and sound from a physics perspective. The best results are obtained by using hyperparameter tuning. This includes altering the learning rate, normalising the batches and controlling dropouts to avoid overfitting. After training, loss functions are examined in order to finetune the precision of output. This ensures that statues made remain artistic while still meeting the fabrication requirements. The products that are produced are rated through a feedback system by human artists. These ratings are then fed back into the model as incentive values. This circular optimisation ensures that things keep getting better by using combination of artistic depth and computation efficiency.

2) Integration

of AI output with 3D printing software

AI-generated models can be fused with 3D printing software to bridge the gap between the imagination generated in the computer and physical objects. These files are denoted by the amateur term STL or OBJ or the professional numerous AMF files. These models, which are usually made up of complicated shapes, goes through post-processing to fix mesh irregularities, get rid of non-manifold edges, and make the topology better so that they can be printed. The digital models that have been improved are put into slicing tools like Cura, Simplify3D or PrusaSlicer so that they are ready to be made. Here, the digital shape of the sculpture is divided into layers and G-code directions are created to instruct the printer on how to move, the temperature to use, and the amount of material to extrude. At this point, AI is still being employed in the effort to find a middle ground between speed, strength and the accuracy in modeling details through automatic parameter optimisation. Super برنada creates algorithms to find the best balance between layers, print direction and filling density. Simulation-based testing is an important part of the process. This is where the print path and structure performance are tested virtually to ensure that there are no issues or deformations that may occur before they are created.

3) Material

selection and printing parameters

In AI-guided sculpture production, the selection of right materials and optimisation of the parameters is very important, both in maintaining the purity of the art and to ensure that the structure is stable. The structure, power, finish and visual effect of a sculpture are all directly affected by the material used. PLA is commonly used for environmentally friendly modeling, as a glue for fine surface textures and composite filaments (additives such as metal or carbon fiber or wood fibers for increased durability and greater variety of appearance). For large projects/tests, you can also use nylon and recyclable plastics. Different materials require different printing parameters, such as the temperature of the extruder, the bed, and the rate of cooling. These settings are measured in order to ensure that the print is stable and the correct size. The smoothness of the surfaces is controlled by layer height which is typically 0.1 to 0.3 mm. The interior strength and weight balance is governed by the filling density ranging from 10 to 100%. Depending on the thickness of the material and the complexity of the design, the speed of printing is changed. For example, slower speeds are required with more precise models.

6. Case Studies and Experimental Results

1) Examples

of AI-generated sculpture prototypes

As a part of that part of the research, a number of sculpture samples were produced by AI to demonstrate what machine-guided creation and additive manufacturing is capable of. A learnt Generative Adversarial Network (GAN) model was used to make more than 100 3D shapes at first. Ten of these shapes were then picked out to be produced in actual form. The prototypes all had a different style, ranging from biomorphic organic shapes to abstract geometrical shapes that shows how different AI-generated designs can be. Parametric modelling tools were used to enhance the accuracy of these models by correcting flaws that were found in the mesh and making the structures stronger. High-precision stereolithography (SLA) and fuse deposition modelling (FDM) 3D printers were used to make the parts, which used materials like plastic, PLA, and carbon-fiber composites. The statues which were made were between 10 and 35 centimetres tall and had complicated internal shapes and surface layers which could not be achieved by hand.

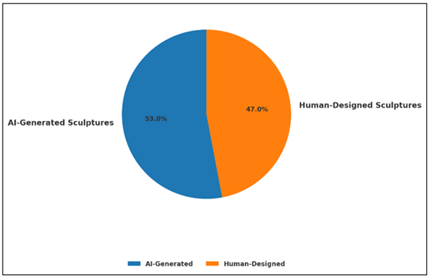

2) Comparative

analysis with human-designed sculptures

A comparison study was done between the AI versions that were made and a control group of sculptures that were drawn by humans and made using standard CAD-assisted processes to see how creative and technically sound the sculptures were. To make sure that the review was fair, the same material, machine type and size factors were used to make both sets of the statues. The comparison was based on three main factors; new looks, complicated structures and how well the products were made. Sculptures created by people had obvious artistic goal, coherent themes, and refinement of style details, which revealed that they were under hands, and conceptual. AI-generated designs, on the other hand, were more formal complexity and had more spatial uncertainty. They were often patterned, unfinished, and curvilinear, not in a sense of conventional symmetry, but in some way in harmony with nature. Quantitative tests revealed that the structure efficiency of the statues created by AI was 10-15% better because algorithms optimised the shape of the insides of the sculptures. This meant that less material was used without having an effect on their stability.

7. Result and Discussion

The results show that art making is much more creative, precise, and efficient with materials when combined with the use of AI with 3D printing. AI-generated versions were more complex in structure and less wasteful in the use of materials than works created by humans. Expert reviews were positive for their creativity and their one-of-a-kind looks, but the emotional depth was still primarily based on human emotions.

Table 2

|

Table 2 Technical Performance Comparison Between AI-Generated and Human-Designed Sculptures |

||

|

Parameter |

AI-Generated Sculptures |

Human-Designed Sculptures |

|

Average Dimensional Accuracy

(%) |

95.6 |

92.4 |

|

Surface Smoothness (μm

deviation) |

18.2 |

16.5 |

|

Structural Stability Index

(0–10 scale) |

9.1 |

8.4 |

|

Material Utilization Efficiency (%) |

88.5 |

76.3 |

|

Average Printing Time

(minutes) |

245 |

210 |

|

Post-Processing Effort (hours) |

1.8 |

1.2 |

|

Printing Error Rate (%) |

3.7 |

5.2 |

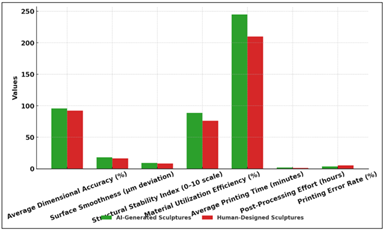

Table 2 shows a comparison that shows AI-generated statues are clearly better than human-designed sculptures in a number of important technical performance measures. The models created by AI had a better precision and a better geometric consistency, a higher structure stability score (9.1/10) and a higher spatial accuracy (95.6%). Figure 3 shows the overall performance comparison between AI generated and human designed sculptures.

Figure 3

Figure 3 Overall Performance Comparison Between AI-Generated

and Human-Designed Sculptures

This is an improvement from AI's mathematical optimisation skills to make complicated shapes better whilst keeping balance and perspective. Also, AI generated designs had a much higher material utilisation efficiency (88.5%), which shows that the system was able to reduce waste through computer modelling and filling optimisation.

Figure 4

Figure 4 Detailed Comparison of 3D Printing Metrics for AI

vs. Human-Designed Sculptures

However, designs based on AI took longer to print (245 minutes) and slightly more work to complete (1.8 hours), because of the more complex shapes and overhangs of the surfaces, which require more support removal and finishing. Figure 4 presents detailed comparison of 3D Printing Metrics for AI vs. human designed sculptures. Even so, AI models had a lower printing mistake rate (3.7%), which implies that the results of manufacturing were more reliable than statues made by humans (5.2%).

8. Conclusion

This study provides proof that the integration of 3D printing technology and artificial intelligence is a gigantic leap in making sculptures in the field. The study shows that AI-guided systems can create complicated aesthetically appealing shapes on their own going beyond the limitations of traditional art. This is done through trial design, theoretical analysis and comparison review. While combined together, machine learning algorithms, CAD-based improvement and additive manufacturing make it possible for more accuracy and creativity than ever before. This allows artists to experiment with structures that were previously difficult to imagine or to create by hand. The results show that the artist's job is changing from being the only creator to being a co-creator and manager working with smart systems, which learn, change and add to the creative process. This collaboration between people and machines offers a broad interpretations of being an author and creative, which opens the way to new ways of making art based on computer aesthetics. AI helps in having better formal creativity and speedy production but people will still need to use their instincts for emotional connection, mental thinking and moral direction. The research is demonstrating that it is easier with AI-guided 3D printing to optimise materials, create designs that work with the different types of materials, and create more environmentally-friendly production. This is in accordance with green practices in the digital manufacturing world. Philosophically, it raises the question of common concepts of originality, authorship, and artistic purpose. It also envisions a world in which humans and computers collaborate to be creative.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Ajani, S., and Wanjari, M. (2013). An Efficient Approach for Clustering Uncertain Data Mining Based on Hash Indexing and Voronoi Clustering. In Proceedings of the 5th International Conference on Computational Intelligence and Communication Networks (CICN 2013). https://doi.org/10.1109/CICN.2013.106

Bende, M., Khandelwal, M., Borgaonkar, D., and Khobragade, P. (2023). VISMA: A Machine Learning Approach to Image Manipulation. In 2023 6th International Conference on Information Systems and Computer Networks (ISCON) (pp. 1–5). IEEE. https://doi.org/10.1109/ISCON57294.2023.10112168

Boretti, A. (2024). A Techno-Economic Perspective on 3D Printing for Aerospace Propulsion. Journal of Manufacturing Processes, 109, 607–614. https://doi.org/10.1016/j.jmapro.2023.12.044

Freeman, S., Calabro, S., Williams, R., Jin, S., Ye, K. (2022). Bioink Formulation and Machine Learning-Empowered Bioprinting Optimization. Frontiers in Bioengineering and Biotechnology, 10, 913579. https://doi.org/10.3389/fbioe.2022.913579

Haque, A. N. M. A., and Naebe, M. (2023). Tensile Properties of Natural Fibre-Reinforced FDM Filaments: A Short Review. Sustainability, 15, 16580. https://doi.org/10.3390/su152416580

Hassan, M., Misra, M., Taylor, G. W., and Mohanty, A. K. (2024). A Review of AI for Optimization of 3D Printing of Sustainable Polymers and Composites. Composites Part C: Open Access, 15, 100513. https://doi.org/10.1016/j.jcomc.2024.100513

Johnson, J. E., Jamil, I. R., Pan, L., Lin, G., and Xu, X. (2025). Bayesian Optimization with Gaussian-Process-Based Active Machine Learning for Improvement of Geometric Accuracy in Projection Multi-Photon 3D Printing. Light: Science and Applications, 14, 56. https://doi.org/10.1038/s41377-024-01707-8

Metal AM. (2023). The Convergence of Additive Manufacturing and Artificial Intelligence: Envisioning a Future that is Closer than you Think. Metal AM.

Panico, A., Corvi, A., Collini, L., and Sciancalepore, C. (2025). Multi Objective Optimization of FDM 3D Printing Parameters set Via Design of Experiments and Machine Learning Algorithms. Scientific Reports, 15, 16753. https://doi.org/10.1038/s41598-025-01016-z

Sheela, M. A. A., Tejaswi, M., Prakash, N. B., Tulasi, M. D. S., and Anitha, K. (2025). IntegriScan: A Graph-Aided Model for Detecting Corrupted and Anomalous Data Patterns. IJRAET, 14(1), 71–78.

Srivastava, M., Aftab, J., and Tyll, L. (2025). The Influence of Artificial Intelligence and Additive Manufacturing on Sustainable Manufacturing Practices and their Effect on Performance. Sustainable Futures, 10, 100820. https://doi.org/10.1016/j.sftr.2025.100820

Thomas, D. J. (2022). Advanced Active-Gas 3D Printing of 436 Stainless Steel for Future Rocket Engine Structure Manufacture. Journal of Manufacturing Processes, 74, 256–265. https://doi.org/10.1016/j.jmapro.2021.12.037

Wang, G., Chen, Y., An, P., Hong, H., Hu, J., and Huang, T. (2023). UAV-YOLOv8: A Small-Object-Detection Model Based on Improved YOLOv8 for UAV Aerial Photography Scenarios. Sensors, 23, 7190. https://doi.org/10.3390/s23167190

Wang, W., Wang, P., Zhang, H., Chen, X., Wang, G., Lu, Y., Chen, M., Liu, H., and Li, J. (2023). A Real-Time Defect Detection Strategy for Additive Manufacturing Processes Based on Deep Learning and Machine Vision Technologies. Micromachines, 15, 28. https://doi.org/10.3390/mi15010028

Yampolskiy, M., Bates, P., Seifi, M., and Shamsaei, N. (2022). State of Security Awareness in the Additive Manufacturing Industry: 2020 Survey. Progress in Additive Manufacturing, 2021, 192–212. https://doi.org/10.1520/STP164420210119

Yeshiwas, T. A., Tiruneh, A. B., and Sisay, M. A. (2025). A Review Article on the Assessment of Additive Manufacturing. Journal of Materials Science: Materials in Engineering, 20, 85. https://doi.org/10.1186/s40712-025-00306-8

Zhou, L., Miller, J., Vezza, J., Mayster, M., Raffay, M., Justice, Q., Al Tamimi, Z., Hansotte, G., Sunkara, L. D., and Bernat, J. (2024). Additive Manufacturing: A Comprehensive Review. Sensors, 24, 2668. https://doi.org/10.3390/s24092668

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2025. All Rights Reserved.