ShodhKosh: Journal of Visual and Performing ArtsISSN (Online): 2582-7472

|

|

AN ANALYSIS OF ERGONOMIC RISK FACTORS ASSOCIATED WITH THE WOOD BLOCK MAKING CRAFT OF PETHAPUR, GUJARAT, INDIA

Vandita Bhatt 1![]()

![]() ,

Dr. Reena Bhatia 2

,

Dr. Reena Bhatia 2![]()

![]()

1 PhD

Scholar, Department of Clothing and Textiles, Faculty of Family and Community

Sciences, The Maharaja Sayajirao University of Baroda, Vadodara, India

2 Assistant

Professor, Department of Clothing and Textiles, Faculty of Family and Community

Sciences, The Maharaja Sayajirao University of Baroda, Vadodara, India

|

|

ABSTRACT |

||

|

The handicrafts sector in India provides employment to a vast number of people contributing to the country's economy; by the vary nature of woodblock making craft, the produce is made with hand- making it labour intensive; spending hours in the same place, health hazards associated occupation. Woodblock makers of Pethapur served as the focal point of the ergonomic study; to render the craft person to be more efficient and productive. The semi structured interview schedule was developed containing a detailed check list for analyzing occupational health hazards using musculoskeletal disorder scale and RULA scale. The results showed that the senior craftsmen experienced pain at various body parts such as joint pain, neck and shoulder pain. It was also discovered that working posture has relation to the body sections that are in pain. It was concluded that there is a need for implementing change in working pattern, workspace arrangement as well as creating awareness amongst the craftsmen about the ergonomic risk factors. The craftsmen need to undergo some physical exercises before performing work which would help in reducing pains. |

|||

|

Received 21 July 2023 Accepted 21 November 2023 Published 14 December 2023 Corresponding Author Vandita

Bhatt, vhbhatt28@gmail.com DOI 10.29121/shodhkosh.v4.i2.2023.605 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2023 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Woodblock

Making Craft, Ergonomic Approach, Musculoskeletal Disorders, Posture Analysis,

Work Environment, Working Pattern, Workshop Arrangement, Ergonomic Awareness,

Efficiency |

|||

1. INTRODUCTION AND background of the study

The

handicrafts sector in India occupies an important position in the country's

economy. There are a vast number of people employed in this sector. It is still

unorganised, and due to this, craftsmen face a number of difficulties in their

craft practices, such as designing, marketing, sourcing raw materials, finance,

communication skills, work efficiency, and occupational health hazards. Pethapur, situated 10 km from the capital city of Gujarat,

Gandhinagar, is one such centre of wood block-making craft. It has been famous

all over the world for its finely carved wooden blocks since the 16th century

BC Posrithong (2013).

Woodblock

is a prerequisite for hand block printing. It is made up of seasoned teakwood.

It requires skill, precision, concentration, and continuous effort to prepare a

perfect block for seamless printing. It is tedious and labour-intensive. It

takes a minimum of three years of training to acquire the craft skills. The

woodblock maker sits for hours in a static position and in complete focus to

achieve accurate and desired results. It was found during the pilot study that,

at present, only a handful of craftsmen practice this craft. The number of

craftsmen presently engaged in this craft is less than twenty. In addition to

this, it was also identified that there is enough work but, due to the lack of

manpower (a smaller number of craftsmen practicing), they are unable to achieve

the target in a given time frame. Therefore, increasing work efficiency could

be one of the possible ways for the craftsmen to perform at a higher level.

From the literature review, it was found that ergonomic studies helped increase

the productivity of the craftsmen in various ways.

As

stated above, making wood blocks is a tedious job, and craftsmen have to sit

for hours in a static position, which causes damage to various body parts,

which affects health and results in work fatigue. Hence, a study was undertaken

to ascertain the occurrence of work-related bodily complaints, identify

ergonomic risks and musculoskeletal disorders (MSD), and examine the work

patterns of the craftsmen and their workplace with an ergonomic approach.

The

present paper discusses the occupational health hazards associated with wood

block making and the work practices of the craftsmen by studying working

posture, working conditions, and the work environment. Additionally, it focuses

on possible solutions for reducing ergonomic risks in order to boost

productivity and ensure the better survival of the craft.

2. Literature review

A

review on similar studies were taken up to understand the various aspect of

ergonomic principles, the procedure of analysing risk, risk factors and

measures to prevent ergonomic risks.

Qutubuddin et al. (2013) studied on

Indian saw mill workers identified work-related musculoskeletal disorders and

ergonomic risks, recommending immediate ergonomic interventions and proper

awareness among workers.

The study by Widana et al. (2018) focused on ergonomic work station design to enhance workload

quality and productivity among craftsmen. Nine samples were tested before and

after treatment, and results showed improved occupational health, decreased

work load, and increased productivity.

According

to the study on Brass Handicraft workers found inadequate ventilation, limited

workshop space, and musculoskeletal complaints at the waist, neck, and

shoulder. They recommended raising awareness about occupational safety and

health Dharmawan et al. (2019). Ergonomics concepts are more

commonly applied in large-scale industries like steel, power, manufacturing,

and automotive, but they can boost worker efficiency by improving tools,

processes, and working environments, reducing pain and disorders Sain et al. (2016).

3. MATERIALS AND METHODS

3.1. Sample selection and locale of the study

The study was conducted in the village of Pethapur near Gandhinagar district, the capital of Gujarat.

The criteria for selecting the sample were the craftsmen who are presently

practicing the craft and the residents of Pethapur

village. The total number of craftsmen practicing the craft was only 15. Hence,

the population selected for the study was fifteen (N = 15), and therefore the

whole population was selected as a sample for the study. The sample

selected for the study was 15 craftsmen from eight existing workshops of

woodblock making situated in Pethapur village itself.

All the participants engaged in the craft study were male artisans.

3.2. Tool used for data collection: Questionnaire study

The Modified Musculoskeletal Questionnaire Bisht and Khan (2019). was used to collect the required information

from the respondents. It was divided into three sections.

·

Demographic and work-related

information, i.e., age, experience, education, marital status, health habits,

working hours, job tasks, workspace-related information, etc.

·

Body part experience discomfort

interview, i.e., pain or discomfort at different body sites, such as the palm,

wrist, and finger regions, knee, and leg (using the body part discomfort scale,

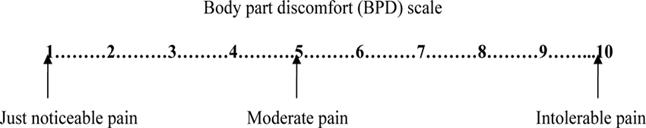

developed by Corlett, E.N., and Bishop, 1976). This is a 10-point scale and is

used to measure the pain experienced by the respondent to determine the degree

of severity of the pain. Figure 1

Figure 1

|

Figure 1 10 Point Body Part Discomfort Scale Corlett and Bishop (1976) Source https://www.researchgate.net/figure/Body-part-discomfort-BPD-scale |

1)

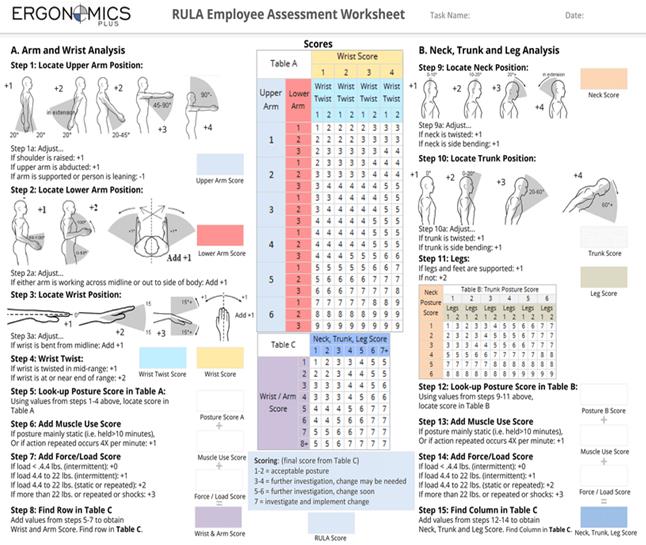

Postural analysis was done using the Rapid Upper Limb Assessment

[RULA] method by the existing craftsmen in Pethapur.

The RULA sheet is a tool to analyse the upper limb body posture, and it helps

to assess the biomechanical and postural load needs of job duties and demands

on the neck, trunk, and upper extremities. A one-page worksheet is used to

assess the necessary repetition, force, and body position. Scores were

entered for each body region in sections; A for the arm and wrist and B for the

neck and trunk based on the evaluations. Tables on the form are then utilised

to assemble the risk factor variables, resulting in a single score that shows

the amount of MSD risk after the data for each location has been gathered and

graded. RULA is a helpful tool in screening the ergonomic risks at the

workplace, as the final score also indicates whether an implantation of change

is required or not. The RULA postural analysis method is considered a

pen-and-paper observation method. Figure 2

Figure

2

|

Figure 2 Rapid Upper Limb Assessment Sheet (RULA) Source https://ergo-plus.com/wp-content/uploads/RULA-A-Step-by-Step-Guide1.pdf |

The

postures maintained for the long duration were considered for analysis.

Postures of the upper arm, lower arm, forearm, and wrist were scored as Posture

A. Force load scores were calculated. Neck, back, and leg postures were

observed and scored as Posture B. All the scores were then added to get the

final score, which determined the ergonomic risk associated with that posture.

The

questionnaire was developed in English and validated by the expert. Each

craftsman was explained about the RULA scale and Nordic questionnaire before

the interview. The questions were verbally explained in local language to the

respondents, and their answers were noted by the researcher. Self-enumeration

was difficult due to craftsmen's lack of understanding of the subject and the

lower literacy level of the majority of participants. The major advantage of

the interviewer-assisted data collection method was that low literacy rates

could be covered, and the response rate and quality of the data could be

increased by personalising the interview.

3.3. Physical

parameters

Physical

parameters such as height and weight were measured using a metal measuring tape

and digital weighing scale (Perfexca). The body mass

index (BMI) was computed from the collected data using a standard equation.

3.4. Sample size and analysis

The sample

selected for the study is equal to the population because the craftsmen engaged

in the craft are 15. Therefore, the whole population has been selected for the

study, which is N = 15, and all the craftsmen selected were residing in Pethapur. The participants were interviewed and observed to

analyse ergonomic risks associated with their age, workload, work pattern, and

work area. The data collected from all the participants was then compared to

find the effect of age, workload, and posture on body discomfort. As sample

size was small, the comparison and analysis were done using

table.

4. RESULTS AND DISCUSSIONS

It is

necessary to understand the tools and techniques of woodblock making before

beginning with the results.

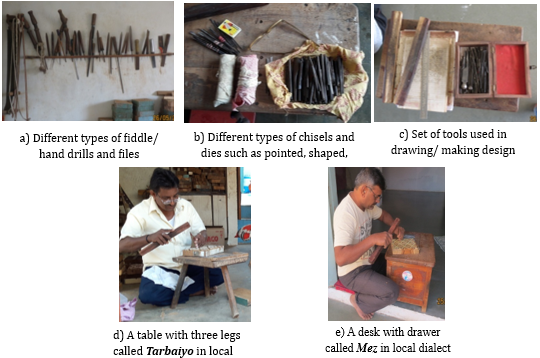

1)

An

introduction to the woodblock-making craft:

For hand

block printing, woodblocks are a necessary instrument. A flawless block must be

prepared for seamless printing with skill, accuracy, focus, and constant work.

It requires a minimum of three years of learning to acquire the craft skills.

It takes three days to carve an outline block. To complete the carving duties,

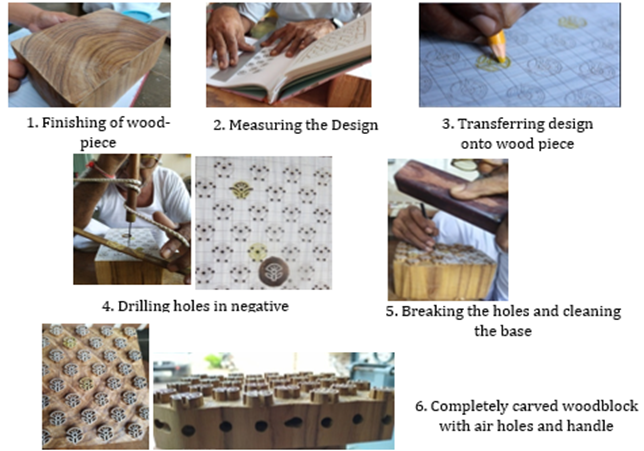

craftsmen must sit motionless for hours at a time. Figure 3 and Figure 4 depict the

equipment needed and the steps involved in creating woodblocks,

respectively.

Figure 3

|

Figure 3 Tools and

Equipment Used in Wood Block Making Source

Image Captured by researcher during field visit, Pethapur |

Figure 4

|

Figure 4 Process of

Wood Block Making Source

Image Captured by Researcher During Field Visit, Pethapur |

The

results are divided into four sections: i)

demographics and work-related information; ii) body part experiencing

discomfort scale; iii) rapid upper limb assessments (RULA); and iv) analysis of

work area and work pattern.

4.1. Demographics and work-task-related information

As

discussed in the methodology, 15 craftsmen were interviewed. Table 1 shows the

demographic details and work-related information. The average or mean BMI index

computed was 23.64 kg/m2, which is considered normal. The daily

working hours spent in craft practice by the respondents were 10 hours,

inclusive of 80–120 minutes of rest each day, and the weekly workload was 70

hours, including 14 hours of rest (7 days working).

The

average age calculated for block makers was 50 years. Six of the 15 craftsmen

were under the age of 40; four were between the ages of 41 and 50; and three

were above the age of 50. It was observed that 80 percent of participants had

education up to the secondary level. From Table 1, it has been

observed that six out of 15 craftsmen have limited work space in their

workshop. It was reported that 50% (four workshops out of eight) of the

workshops were run single-handedly by the craftsmen themselves, i.e., four

craftsmen were working without any assistant in their workshop. Hence, they

have to complete all the tasks alone, which results in work-related fatigue and

affects work efficiency.

Table 1

|

Table 1 Demographic and Job Task Related Information (n=15) |

|||

|

No. |

Category |

No. of Respondents (n=15) |

|

|

1 |

Age |

31-40 |

5 |

|

41-50 |

4 |

||

|

51 & above |

5 |

||

|

2 |

Education |

Illiterate |

1 |

|

Primary |

4 |

||

|

Secondary |

9 |

||

|

Graduate |

1 |

||

|

3 |

Experience |

5-20 years |

7 |

|

21-40 years |

4 |

||

|

41 years & above |

4 |

||

|

4 |

Working hours |

08 hrs |

13 |

|

10 hrs |

2 |

||

|

5 |

Breaking time |

2-5 time |

8 |

|

> 5 time |

7 |

||

|

6 |

Resting time |

1 hour |

|

|

2 hour |

15 |

||

|

7 |

Working pattern |

Alone |

6 |

|

With Assistant |

9 |

||

|

8 |

Do you carry your work monthly at same workplace? |

Yes |

15 |

|

No |

|||

|

9 |

Work rotation with colleagues |

Yes |

8 |

|

No |

7 |

||

|

10 |

Repetitive work |

Yes |

9 |

|

No |

6 |

||

|

11 |

Workshop having sufficient space |

Yes |

9 |

|

No |

6 |

||

|

12 |

Enough sunlight and air circulation/ proper

ventilation |

Yes |

13 |

|

No |

2 |

||

|

13 |

Use of any mechanized tools to reduce physical

activity/ reduce load |

Yes |

13 |

|

No |

2 |

||

|

14 |

Environmental or other factors that affects work

production/ create disturbance? |

||

|

Temperature |

3 |

||

|

Humidity |

15 |

||

|

Noise |

|||

|

Other than this please specify |

|||

|

14 |

Use of back rest for supporting upper back |

Yes |

6 |

|

No |

9 |

||

|

15 |

Use of cushion while working sitting on floor |

Yes |

15 |

|

No |

|||

|

16 |

Job tasks |

a) Finishing of wood piece |

8 |

|

b) Transferring design on to wood piece |

8 |

||

|

c) carving process |

9 |

||

|

d) Finishing of carved wooden block |

10 |

||

The

craft is practiced by sitting on the floor continuously in the same posture.

All of them use cushions for sitting, but nine craftsmen work without back

support. It was also reported that, according to the work pattern, craftsmen

undergo repetitive and continuous work. This caused musculoskeletal disorders

as well as pain and discomfort. There was no significant problem with eyesight

observed among the participants, as they preferred to work in sunlight. It

might be stated that in this case, long-term eye problems would be developed.

All

the craftsmen face disturbances in their work due to humidity during the rainy

season, as wood dust clumps to the wood and doesn’t come out easily from the

drilled part. In addition to this, less sunlight during the monsoon season also

creates work hindrances. 13 out of 15 craftsmen use mechanised tools such as a

trimmer, grinder, and hand drill for the finishing of wood pieces, i.e., the

preparatory process. This resulted in saving time and energy and increasing

productivity by maintaining quality. At the same time, it was reported that

many of them faced the problem of breathing. The wood dust produced from

grinding applications may cause a range of health hazards since grinding dust

tends to affect the respiratory system as well as spread throughout the work

area and environment quickly Mahmood et al. (2021). To address the

lighting and wood dust issues, this requires immediate attention and action.

4.2. Body part experiencing discomfort

Table 2

|

Table 2 Most Affected Body Part Experience Discomfort |

||||||||

|

Age |

Level

of Discomfort |

|||||||

|

ND

(n) |

LD |

MD |

SD |

DD |

UBD

(n) |

|||

|

(n) |

(n) |

(n) |

(n) |

|||||

|

31-40 |

Most

affected body parts |

|||||||

|

(n=5) |

Neck |

2 |

3 |

|||||

|

lower back |

2 |

3 |

||||||

|

lower leg |

4 |

1 |

||||||

|

knee |

3 |

2 |

||||||

|

Vision |

5 |

|||||||

|

Breathing problem |

3 |

1 |

1 |

|||||

|

Neck |

4 |

3 |

||||||

|

41-50 |

lower back |

3 |

2 |

|||||

|

(n=5) |

lower leg |

4 |

2 |

|||||

|

knee |

3 |

2 |

||||||

|

Vision |

4 |

1 |

||||||

|

Breathing problem |

3 |

2 |

||||||

|

Neck |

3 |

|||||||

|

51 & above |

lower back |

1 |

2 |

|

|

|||

|

(n=5) |

lower leg |

2 |

1 |

1 |

1 |

|||

|

knee |

1 |

2 |

2 |

|||||

|

Vision |

3 |

2 |

||||||

|

Breathing

problem |

3 |

2 |

||||||

|

*(n)= No. of respondents facing discomfort, ND- No Discomfort, LD- Light

Discomfort, MD- derate discomfort, SD- Strong Discomfort, DD- Disruptive

Discomfort |

||||||||

The results from the body part experiencing

discomfort scale were used to measure the level of discomfort experienced at

various regions of the body Mrunalini and Logeswari (2016). The light (LD)to moderate (MD) pain in neck was

reported amongst the 9 craftsmen. From Table 2, it is observed that most of the senior artisans

experienced this kind of pain regularly. The amount of disorder and pain

increases in the young generation at times of severe work load. Most of the

senior artisans (n = 5) experienced moderate (MD) to strong discomfort (SD) in

neck, lower back, lower leg and knee. Therefore, it can be said that the amount

of pain increased with the exertion at work as well as increased with the

growing age. There is an association with age as well as work exertion to the

Musculoskeletal Disorders (MSDs).

4.3. Postural analysis

The rapid upper limb analysis scale was 4 and 5.

The postural score of nine craftsmen was 4. The results indicated that

discomfort was more likely to occur in the neck and trunk. Based on the results

of the RULA assessment, the majority of participants needed more research

before making any changes Table 3.

The results from Nordic questionnaire

discovered that body part most affected by pain were the neck, lower back,

lower leg and knee.

Table 3

|

Table

3 Frequency Distribution of Exposure to Ergonomic

Risk Factors in Woodblock Makers RULA Score |

||

|

Statement |

Frequency |

|

|

1-2 |

Acceptable posture |

0 |

|

3-4 |

Further investigation and change may be

needed |

9 |

|

5-6 |

Further investigation, change soon |

6 |

|

7 |

Investigate and implement change |

0 |

The study was undertaken by observing the

postures and work space arrangement. The postural analysis and the work space

arrangement presented below are supported with photographs and analyzed with descriptions.

4.3.1. Working posture

There

are different stages of the block-making process, as shown in Figure 2. The postures differ according to the process or stage of

block-making. The craftsmen need to sit continuously for hours for the carving

process. There are four stages of woodblock making: a) finishing of the wood

piece; b) transferring design to the wood piece; c) actual carving; d) handle

attachment; and e) finishing of the carved woodblock. The process of finishing

a rough wood piece takes immense physical exertion and time. Although the use

of mechanised tools has reduced physical exertion by saving time and energy and

increasing the productivity of craftsmen.

The process of carving is tedious, and

craftsmen have to sit continuously in the same posture for hours. It takes a

minimum of three days to carve an outline block. The body parts involved and

affected in the carving process were the eye, neck, lower back, hand, and arm,

and the craftsmen worked in the same static position while carving. Thus, the

degree of stress associated with this position was examined. The majority of

responders were found to work and sit without back support. It was noted that

artisans would adjust their seating positions based on what was most

comfortable for them (Figure 5 and Figure 6).

Position

A: It has been observed, based on Figure 5, that some

craftsmen used to sit in a folded-leg posture. Due to this, pain in the lower

leg and knee has been reported.

Position

B: Some of the craftsmen used to sit on their paws or by keeping one leg

half-folded so that the elbows and arms got support from the knee and the arm

stayed in the rest position (Figure 6).

During

the carving process, one hand was used to hold the chisel while the other held

the mallet, which was used to repeatedly tap on the chisel. Two different kinds

of mallets were employed. One weighs 800 g, which is heavier and was used to

break the wood piece; the other weighs 500 g, which is lighter and was used for

carving and tracing. The mallet used is about a foot long, allowing the

craftsmen to handle it properly and conveniently (Figure 7).

Figure 5

|

Figure 5 Craftsmen at Work: Working Position A Source Image Captured by Researcher

During Field Visit, Pethapur |

Figure 6

|

Figure 6 Craftsmen at Work: Working Position B Source Image Captured by Researcher

During Field Visit, Pethapur |

Figure 7

|

Figure 7 A Mallet Used in Carving (weight: 500 gm) Source Image Captured by Researcher During Field Visit, Pethapur |

Figure 8

|

Figure 8 Work Area and Workshop Arrangement Source Image Captured

by Researcher During Field Visit, Pethapur

|

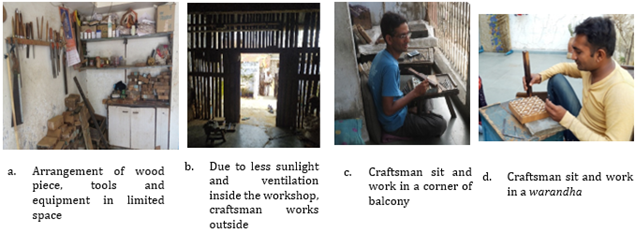

4.3.2. Work space and work environment

All the workshops were visited, and each

workshop was observed and analysed on the basis of ergonomic principles to

suggest interventions that need to be implemented.

Most of the workshops were attached to their

dwellings, such as the warandha or balcony, or

on a separate floor or a separate room used for the workshops, except for one

that was rented and a mile away from the residence. Due to this, craftsmen have

to attend to guests and do some household work, which interrupts the continuity

of the work. It was observed that, out of eight workshops, six needed

rearrangements of tools and space. It was observed that, due to the limited work space, they used to keep

tools in a wooden box or metal trunk. This has made work more difficult

and reduced productivity as craftsmen had to place things aside, then take out

their equipment and rearrange the table when they returned to their jobs. Due

to the time and energy consumed on repetitive tasks led to work-related fatigue

and a decrease in concentration, focus, and interest (Figure 8).

It was found that four out of eight workshops

were well maintained and in good condition. The rest of the four workshops need

improvement by reorganising the tools and other stuff to create a better

working area and avoid interruptions during work. There was enough sunlight and

ventilation in the workshops. It was observed that most of the craftsmen used

to mount the cutting and finishing tools with hooks on the wall. The small

tools, such as chisels, punches, and dies, were used to be put in a drawer of

table, sides of the table or in a separate box. Although all the respondents

used to keep the required tools within their reach, it would save time and

energy as we reduce physical activity during work.

It was reported that during the monsoon

season, work efficiency is affected due to less sunlight, and wood gets

affected by the moisture, so it becomes tricky for the craftsmen to remove wood

dust from the drilled part because when wood is moist, wood dust clumps

together and forms an impermeable barrier that does not allow air or heat to

pass through.

4.3.2.1. Work pattern

Based

on observations and interviews, it was found that in three of the nine

workshops, there were two or three artisans working as assistants. The other

artisans all labour on their own, without help. As a result, the craftsmen's

workload increased, and they were unable to meet the deadline. Despite the fact

that using mechanised equipment has decreased workload by conserving energy and

time, there are still other tedious tasks to be taken into consideration

(starting from procuring wood to packaging and shipping woodblocks). Hence, it

is important to educate the craftsmen about an organised workspace and

systematic working patterns.

It

was discovered that most artisans were forced to work at random due to the

limited workspace, low labour force, and large order list. As a result, there

was fatigue and reduced work efficiency.

The

way a workplace is designed has a significant effect on employee productivity.

Making the best use of space through optimum placement of equipment,

integrating human factors into workplace design, and effectively aligning the

workplace with the surrounding environment are important aspects of ergonomics Thomas (2012). Hence it was apparent that reorganizing the workspace

by following ergonomic principles will help to improve productivity.

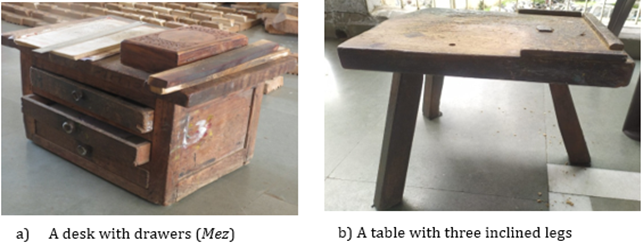

4.3.2.2. Ergonomic

analysis of table used for block making

A

table is the most essential and basic piece of equipment used in block making.

Two types of tables were used: one with three inclined legs is called tarbaiyo in the local language, and the other is a

desk called mez. (Figure 9) The

specification of the table used is shown in the table below. It was observed

that the tables used by the craftsmen were in different sizes, with minor

variations.

Figure 9

|

Figure 9 Tables

Used in Wood Block Making Source

Image Captured by Researcher During Field Visit, Pethapur |

A table with three inclined legs (tarbaiyo): This type of

table is used mainly for carving. It has been used by the craftsmen for many

years since the origin of the block-making craft. By observation and interview,

it can be said that Tarbaiyo has been

designed keeping in mind the following details:

·

Due to its three inclined legs, it doesn’t move while

carving.

·

Three legs allow easy movement of the leg.

·

The board (surface of the table) can withstand weight or

pressure exerted with a mallet since it is sturdy and thick enough.

·

To keep the dies and chisels steady and from collapsing off

the table, one side of the table features 1 cm-high edges (Figure 9b).

Desk (Mez): A desk is

generally used for drawing or tracing the design. It was made up of four legs

and had two or three drawers to keep the drawing tools within reach. The base

of a desk had a flat surface and was used for drawing. Some of the craftsmen

are also comfortable using a desk to perform all types of work, including

drawing, tracing, and carving.

·

Drawers make the tools easily

accessible, such as different chisels, dies, and drawing tools such scales,

compass, colour pencils, paint, mallets, and design papers, within reach of the

craftsmen.

·

There is a limited amount of

space for comfortable leg movement because of the drawers (Figure 9a).

At each workshop, the length, width, height, and

thickness of both types of tables were measured. A small amount of variance

between dimensions was noted between the tables each artist utilised in his

various workshops. The average dimension was then measured after that. Table 3 indicates that the average height of the three-legged Tarbaiyo table was 14.5" x 17.5" x 11" (L x

B x H), and the average size of a desk was 11.5" x 14.5" x 13.5"

(L x B x H). It has been estimated that the height of the table was nearly one

foot based on average size (Table 4).

Table 4

|

Table 4 Specifications of Table Used in Wood Block Making |

||||||

|

Dimensions |

L |

B |

H |

L |

B |

H |

|

|

11.5” |

14” |

13.5” |

14.5” |

17.5” |

11” |

|

Thickness of board/base |

1” |

1.5” |

||||

|

Wood used in making |

Teakwood |

Teakwood |

||||

|

Drawers |

Yes, two or three |

No |

||||

|

Legs |

four |

Three |

||||

|

Use |

Used in drawing and tracing of design |

Used in carving process |

||||

|

limitations |

Restricted leg movement |

Less space for keeping tools. |

||||

|

Height of table: |

|

|

||||

It

was noted during the interview that the height of the tables was adjusted in accordance

with the user's height; craftsmen would either place a wood piece under the

actual wood block to increase height or keep a stone or wood piece under the

table leg to adjust the height of the table (Figure 10). Since doing

otherwise might affect work posture and raise the risk of ergonomic hazards, it

can be said that the height of the table should be proportionate to the height

of the craftsman.

Figure 10

|

Figure 10 Craftsmen Used to Place Wood Piece or Stone to Make the Table Source Images Captured by the Researcher

During the Field Visit at Pethapur |

The

results of current study are supported with related literature. The study by Mahmood et al. (2021) found that upper extremity musculoskeletal

disorders and ergonomic risk exposure among Pakistani handicraft workers,

particularly the neck and shoulder, necessitate changes in working conditions.

Musculoskeletal problems were identified as a serious issue among craftsmen by Mrunalini and Logeswari (2016) in their

review, which emphasised the necessity for corrective actions to decrease

ergonomic risks. A study found that workers in saw mills face moderate to high

risk of musculoskeletal disorders due to manual work and lack of awareness

about ergonomics and proper postures. Small scale industries and handicraft

sectors were lacking with the awareness about ergonomics, good work

environment, right postures etc Sain and Meena (2016). According to

the study conducted by Caballer (2016) on school desk

suggests that school desks should be adjustable in height to accommodate

students of varying heights, ensuring comfort and ease of use.

5. Conclusions and Recommended Remedies

After

Significant ergonomic risks and hazards have been identified after an ergonomic

assessment. These were classified in order of urgency, and possible solutions

were given to overcome the ergonomic risks and increase productivity. The

proposed suggestive measures were derived from research on related issues that

applied and assessed ergonomic principles. The ergonomic risks associated with

the craft and its possible solutions have been discussed in detail below and

supported by the related literature.

|

Factors identified: Natural light provision and use of

artificial lighting |

|

|

Some workshops were found to have less

sunlight hence craftsmen had to work outside the workshop |

Skylights can be incorporated to get

maximum amount of sunlight |

|

During monsoon season, due to cloudy

weather less sunlight observed and that creates work hinderance |

Appropriate artificial lighting and

lamps with efficient light output such as T5 tube-light or LED lighting

systems can be used with less maintenance and do not produce any glare.1

|

|

Factors identified: Exposure to wood dust Shavings should

always be vacuumed up at the source wherever possible |

|

|

·

wood dust produced from grinding applications may

cause a range of health hazards since grinding dust tends to affect the respiratory

system |

·

OSHA recommends an eight-hour exposure limit of 5

mg/m3 for hard wood and soft wood. ·

Wearing masks and apron can minimize the risk

6 ·

Suction devices must be used to keep dust and

shavings from accumulating in the workspace. Shavings should always be

vacuumed up at the source16 |

|

·

Factors identified:

Adjustable desk |

|

|

Desk/table used for carving |

|

|

Craftsmen need to do adjustment in the

existing table to adjust height Need to overcome the limitations of

both kind of tables. |

·

By

maintaining the traditional design of the table with adjustable height, side

drawers or panels to store tools, and additional space, it is possible to

remodel it in accordance with ergonomic principles and the necessary

specifications. |

|

Factors

identified: Awareness |

|

|

The craftsmen were not aware of

ergonomic risks and occupational health hazards. |

·

There is a need

to familiarize young craftsmen by means of training with the term ‘ergonomics’

and impart knowledge of some physical exercises to reduce the level of pain

and for relaxation. |

|

·

Factors

identified: Policy planning |

|

|

·

Handicraft

sectors given least attention to ergonomic work place and its risk factors |

·

The government

needs to take initiatives to develop ergonomic workplaces in the craft sector

by providing financial support or subsidies to develop ergonomic

infrastructure ·

Create and

implement policies governing the ergonomic risks associated with craft

industries to help artisans 14. |

|

·

Factors

identified: Work pattern |

|

|

It was observed that

craftsmen used to take one long break of two hours in noon and working hours

were 8 in the morning to 6 in the evening |

·

The two-hour

lunch break could be split up into two or three shorter ones. One hour of

relaxing and one hour of lunch break, for instance, can be split up into

little intervals of fifteen or thirty minutes each. It might save time, and

additional time could be spent on bodily relaxation by increasing work

efficiency. ·

Increasing the

number of working hours per day and modifying work schedules have been

recommended to increase productivity. ·

Dividing work

according to the environment would benefit the craftsmen by boosting output

and eliminating fatigue. For example, intricate work like drawing and carving

should be done during daylight, while attaching handles and packaging can be

done in the evening. |

|

·

Factors

identified: Work area and work space |

|

|

·

Less manpower, pending orders, and limited

work space resulted in work fatigue and affected the work efficiency. ·

Most of the

workshops were located in the residence or were part of the dwellings. The

interruptions faced during work were due to family members, household work,

attending guests, children playing around, etc. |

·

Rearranging the

workspace: Arranging tools

and equipment in a more systematic manner will help the workplace overcome

fatigue and increase productivity. ·

Workstation

design: Create a

workspace or corner where artisans can focus better and work without

distractions. |

6. CONCLUSION

Craftsmen spent hours at a time in a static

position at the same place, according to observations and research findings.

Age and work exertion were found to have significant associations with

musculoskeletal disorders. Senior artisans reportedly complained of severe to

crippling lower back and knee pain. With higher exertion and longer work in the

same posture, discomfort increases. The paper states that the RULA score

indicated the need for further investigation on postural analysis and the

implementation of change. There is need to aware young craftsmen about the

ergonomic risks and its importance.

It was found that during the monsoon, work

efficiency was affected due to less sunlight. An adequate artificial light

source in workshops is needed to work smoothly in cloudy weather.

Wood dust produced with the use of a grinder and

trimmer can cause serious damage to the health of the craftsmen. It would

affect the respiratory system and cause skin allergies. It is intended to

remove wood dust in an appropriate manner. Vacuum suction can be used to

accomplish this. Floor chair with adjustable back support can be useful.

Further research needs to be done by designing a

workstation, applying ergonomic principles, and analysing its impact.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

The researcher is thankful to all the respondents for their support and patience while answering the questions and giving their valuable time despite their busy schedules. The researcher acknowledges the support of the Indian Council of Social Science Research (ICSSR) for the opportunity of a doctoral fellowship.

REFERENCES

Bansal, V. (2020). Role of Lighting in Wood Carving Procedure.

Bisht, D and Khan, M. (2019). 'Handle Design of Woodworking Tools: Preferences and Recommendations of Craftsmen and Design Students', International Journal of Advanced Production and Industrial Engineering, 5 (2), 40-47. https://doi.org/10.35121/ijapie202004245

Caballer, M. (2016).

Design of an Adjustable Table, Project of Bachelor Programme, School of

Engineering, Jonkoping University,

Sweden.

Daub, U. et al. (2018).

Ergonomic Workplace Design: Musculoskeletal Principles Deriving

Through from the Exercise,

Sports and Human Factor Sciences, Fraunhofer Institute for Manufacturing,

Engineering and Automation IPA, Stuttgart, Germany.

Dharmawan, Y., Setyaningsih, Y. U. L. I. A. N. I., & Prasetyaningrum, A. (2019). Work Environment and Musculoskeletal Complaints of Grinding Workers of Brass Crafts. In Journal of Physics: Conference Series, IOP Publishing. 1217 (1), 012160. https://doi.org/10.1088/1742-6596/1217/1/012160

Eldridge. (2021). Wood

Dust Exposure and Lung Cancer: Risk of Cancer and Other Health Conditions from Hard and Soft Wood Dust.

Industrial Vacuum Cleaners for Sawdust and Wood Dust (n.d.).

Kamti, K. et al. (2018). 'Occupational Health Profile of Workers in Terracotta Handicraft Industry: Ergonomics Intervention', In: Bijulal, D., Regi Kumar, V., Subramoniam, S., Iqbal, R., Khanzode, V.(eds), Technology-Enabled Work-System Design, Design Science and Innovation, Proceedings of HWWE 2018: International Conference on Humainzing Work and Work Environement. Springer, Singapore, 149-159. https://doi.org/10.1007/978-981-16-1884-0_15

Mahmood, W. et al. (2021). 'Upper Extremity Musculoskeletal Disorders and Exposure to Ergonomic Risk Factors Among Handicraft Workers', Pakistan Journal of Medical Sciences, 37 (2), 494. https://doi.org/10.12669/pjms.37.2.749

Mrunalini, A., and Logeswari, S. (2016). 'Musculoskeletal Problems of Artisans in Informal Sector-a Review Study'. International Journal of Environment and Ecology, Family and Urban Studies, 6 (1), 163-170.

Posrithong, P. (2013). 'Indian Trade Textiles as Thai Legacy', in Chandra, S. et al (Eds), The Sea, Identity and History: from the Bay of Bengal to the South China Sea. ISEAS Publishing, Institute of Southeast Asian Studies, 329-348. https://doi.org/10.1080/00856401.2014.890503

Qutubuddin, et al., (2013). An Ergonomic Study of Work-Related Musculoskeletal Disorder Risks in Indian Saw Mills. Journal of Mechanical and Civil Engineering, 7 (5), 7-13.

Sain, M.

K., & Meena, M. L. (2016). Occupational Health and Ergonomic Intervention

in Indian Small-Scale Industries: a Review.

Int J Recent Adv Mechanical

Engin, 5(1), 13-24.

Shrestha, R. (2011). "Craft's

village." India: Tribhuvan

University, Institute of Engineering Recuperado de.

Singh, A. et al (2019). 'Musculoskeletal Risk Assessment among the Male Workers Engaged in Craft Sectors of Jaipur, India, Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, March© IEOM Society International, 5-7, 763-770.

Thomas, J. (2012). Ergonomics

and Workplace Design.

Widana, I. K., Sumetri, N. W., and Sutapa, I. K. (2018). "Ergonomic Work Station Design to Improve Workload Quality and Productivity of the Craftsmen." Journal of Physics: Conference Series, IOP Publishing, 953 (1). https://doi.org/10.1088/1742-6596/953/1/012091

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© ShodhKosh 2023. All Rights Reserved.